Sep . 19, 2025 17:55 Back to list

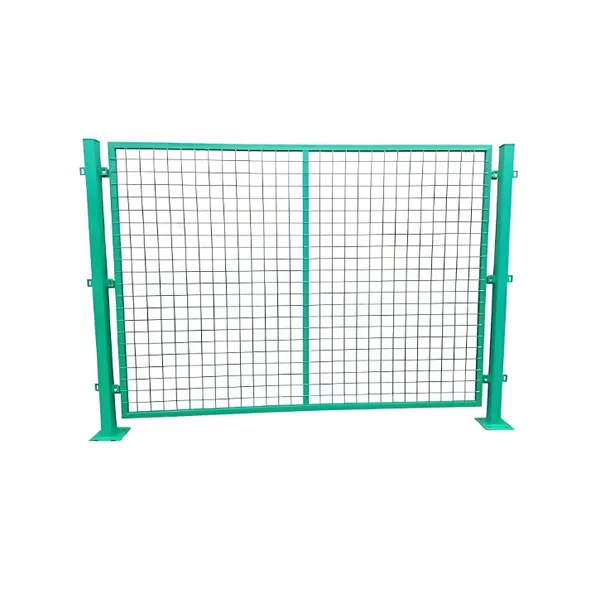

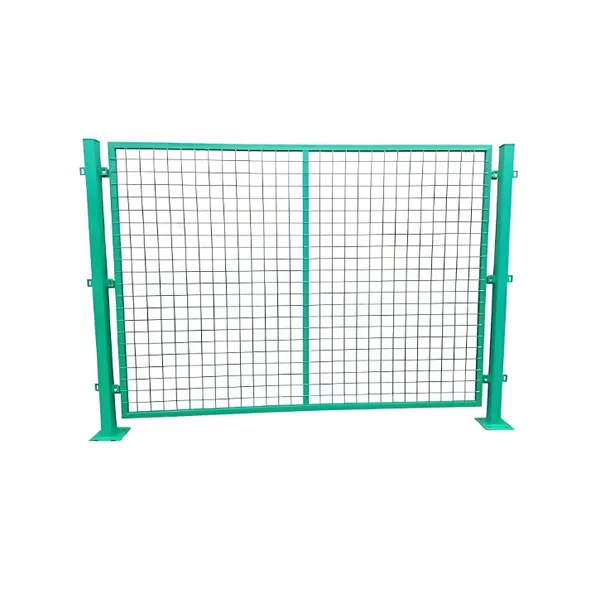

Durable PVC Coated Wire Mesh Panels | Quality Manufacturers

Understanding PVC Coated Wire Mesh in Industrial Applications

In diverse industrial and commercial sectors, the demand for robust, corrosion-resistant, and aesthetically pleasing fencing and containment solutions is paramount. PVC coated wire mesh represents a superior engineering solution, combining the structural integrity of steel wire with the protective and decorative qualities of polyvinyl chloride. This advanced material is engineered to withstand harsh environmental conditions, providing extended service life and reduced maintenance in critical infrastructure projects, security perimeters, and specialized animal enclosures. Its application spans across various demanding environments, offering a versatile alternative to traditional galvanized options.

The strategic integration of PVC coating enhances the innate strength of welded or woven wire mesh, creating a barrier that is highly resistant to rust, chemical exposure, and UV degradation. This section will delve into the intricate manufacturing process, highlight key technical specifications, explore prevalent application scenarios, and articulate the distinct advantages that position this material as a preferred choice among B2B decision-makers and engineers.

Detailed Manufacturing Process Flow of PVC Coated Wire Mesh

The production of high-quality pvc coated wire mesh involves a sophisticated multi-stage process, ensuring both structural integrity and superior protective properties. This meticulous manufacturing chain underpins the product's extended service life and performance in challenging environments.

1. Raw Material Sourcing and Preparation

The foundation of our PVC Coated Welded Wire Mesh begins with premium low-carbon steel wire. This wire typically conforms to ASTM A641 or equivalent international standards, ensuring optimal tensile strength and ductility. Upon receipt, the raw wire coils undergo rigorous inspection for diameter consistency, surface imperfections, and material composition.

2. Welding or Weaving the Mesh Base

- Welded Wire Mesh: Precision welding machines utilize electrical resistance welding to fuse intersecting steel wires, creating a strong, uniform grid pattern. The welding parameters (current, pressure, time) are precisely controlled to ensure consistent weld strength across the entire mesh panel, meeting ISO 9001 quality standards.

- Woven Wire Mesh: For woven variants, steel wires are interlaced on specialized looms, forming various weave patterns such as plain weave or twill weave, depending on the desired flexibility and aperture size.

3. Pre-treatment and Cleaning

Before PVC application, the mesh base undergoes a comprehensive cleaning and pre-treatment process crucial for adhesion. This typically includes:

- Degreasing: Removal of oils, greases, and contaminants using alkaline or acidic solutions.

- Rinsing: Multiple stages of rinsing with deionized water to eliminate chemical residues.

- Phosphating/Chromating: Application of a conversion coating to enhance corrosion resistance and provide an excellent bonding surface for the PVC. This step is critical for long-term adhesion.

- Drying: Thorough drying in ovens to ensure no moisture interferes with the subsequent coating process.

4. PVC Coating Application

This is the defining step where the wire mesh receives its protective PVC layer. Two primary methods are employed:

- Fluidized Bed Dipping: The pre-heated mesh is immersed into a tank of finely powdered PVC resin, fluidized by air. The heat from the mesh melts the PVC powder upon contact, creating a uniform, thick coating. This method is renowned for achieving excellent edge coverage and consistent thickness, typically resulting in coating thicknesses of 0.3mm to 1.0mm.

- Electrostatic Spraying: For certain applications or aesthetic finishes, PVC powder can be electrostatically charged and sprayed onto the grounded mesh. This method allows for thinner, more controlled coating layers.

5. Curing and Cooling

After coating, the mesh enters a curing oven where the PVC is thermoset at elevated temperatures (typically 180-220°C). This process ensures the polymer fully cross-links, achieving its final hardness, adhesion, and chemical resistance properties. Subsequent controlled cooling prevents warping and maintains material integrity.

6. Quality Control and Testing Standards

Each batch of PVC Coated Welded Wire Mesh undergoes rigorous quality assurance. Testing standards include:

- Adhesion Test: ASTM D3359 (Cross-Cut Tape Test) to ensure PVC bonding.

- Coating Thickness Measurement: Using eddy current or magnetic induction gauges, conforming to ISO 2808.

- Corrosion Resistance: Salt spray testing (ASTM B117) demonstrates superior resistance, often exceeding 1000 hours without red rust.

- UV Resistance: Accelerated weathering tests (ASTM G154 or ISO 4892) confirm color stability and material integrity under prolonged sun exposure.

- Tensile Strength: Of the underlying wire and overall mesh structure, per ASTM A641.

- Dimensional Accuracy: Mesh aperture and panel dimensions checked against ANSI/AWWA C203-15 or project-specific requirements.

7. Cutting, Packaging, and Dispatch

Finished rolls or panels are cut to specified dimensions, carefully inspected, and packaged to prevent damage during transit. The expected service life of properly installed and maintained pvc coated wire mesh in typical outdoor environments can range from 15 to 25 years, significantly outperforming uncoated or galvanized-only alternatives. This extended lifespan provides exceptional long-term value.

Target Industries and Advantages

The robust nature of pvc coated wire mesh makes it indispensable across diverse sectors:

- Petrochemical: For security fencing around refineries, storage tanks, and pipelines, offering corrosion resistance against chemical spills and saline atmospheres.

- Metallurgy: Creating secure enclosures within processing plants where dust and chemical vapors are prevalent.

- Water Supply & Drainage: Used in treatment plants for access control, equipment protection, and filtration screens, benefiting from its resistance to moisture and microbial growth.

- Agriculture & Animal Husbandry: Durable, safe enclosures for livestock and crops, resisting weather and animal wear.

- Construction & Infrastructure: Permanent security fencing, bridge reinforcement, and erosion control.

In these scenarios, the advantages extend beyond corrosion resistance. The material offers energy saving benefits in contexts requiring low thermal conductivity, and its aesthetic versatility contributes to better site integration and enhanced safety.

Industry Trends and Technical Specifications

The market for pvc coated wire mesh is constantly evolving, driven by innovations in material science, environmental regulations, and increasing demands for enhanced security and durability. Current trends indicate a shift towards more sustainable PVC formulations, specialized color matching for architectural integration, and increased adoption of automated manufacturing processes to ensure consistent quality and efficiency.

Emerging Trends:

- Eco-Friendly Formulations: Development of phthalate-free and lead-free PVC compounds to meet stricter environmental standards and health regulations, particularly in applications exposed to the public.

- Smart Fencing Integration: Growing demand for mesh solutions that can integrate with smart security systems, incorporating sensors for intrusion detection or surveillance equipment.

- Architectural Aesthetics: Increased emphasis on aesthetic appeal, leading to a wider range of custom colors and finishes that blend seamlessly with modern architectural designs, especially for urban infrastructure projects.

- Enhanced UV Stability: Continuous improvements in UV stabilizers to provide even longer-lasting color retention and material integrity in extreme solar exposure environments.

Key Technical Specifications:

Understanding the precise technical parameters is crucial for selecting the appropriate pvc coated wire mesh for any given project. Below is a typical specification table for standard industrial-grade PVC coated welded wire mesh panels.

| Parameter | Specification Range | Standard Met / Notes |

|---|---|---|

| Mesh Aperture (Opening) | 1/2" x 1/2" to 4" x 4" (12.7x12.7mm to 101.6x101.6mm) | Custom sizes available |

| Wire Gauge (Before Coating) | 16 AWG (1.6mm) to 8 AWG (4.0mm) | ANSI/AWG B36.10M-2015 |

| Overall Wire Diameter (After Coating) | Typically 2.0mm to 5.0mm (0.08" to 0.2") | Ensures minimum PVC thickness |

| PVC Coating Thickness | 0.3mm to 1.0mm (0.012" to 0.04") per side | ISO 2808, adjustable for application |

| Tensile Strength (Coated Wire) | Min. 450 MPa (65,000 psi) | ASTM A641, ISO 6892-1 |

| Corrosion Resistance (Salt Spray) | > 1000 hours (no red rust) | ASTM B117, ISO 9227 (NSS) |

| UV Resistance | Excellent (5+ years against significant color fade/degradation) | ASTM G154, ISO 4892 |

| Temperature Range (Operating) | -30°C to +70°C (-22°F to +158°F) | Ensures performance in varied climates |

| Standard Colors | Dark Green (RAL 6005), Black (RAL 9005), Grey (RAL 7016) | Custom RAL colors available |

These specifications highlight the material's engineering robustness, critical for applications where reliability and longevity are non-negotiable.

Versatile Application Scenarios for PVC Coated Wire Mesh

The inherent strength, flexibility, and superior corrosion resistance of pvc coated wire mesh make it an exceptionally versatile material, finding critical applications across a broad spectrum of industries. Its ability to perform reliably in harsh outdoor conditions, coupled with its aesthetic appeal, positions it as a preferred solution for both functional and visual requirements.

1. Security and Perimeter Fencing

- Industrial Facilities: High-security fencing around power plants, data centers, manufacturing sites, and chemical processing facilities. The PVC coating offers protection against chemical exposure and extends the life of the barrier.

- Commercial Properties: Schools, parks, and retail centers benefit from durable and aesthetically pleasing perimeter control, deterring unauthorized access while blending with the landscape.

- Military & Government Sites: Robust security enclosures where long-term integrity and resistance to tampering are critical.

2. Animal Containment and Agriculture

- Zoological Parks & Wildlife Sanctuaries: Creating safe and humane enclosures for various animal species, where the smooth PVC surface prevents injuries and resists corrosive animal waste.

- Farm Fencing: Durable and weather-resistant fencing for livestock, poultry runs, and garden protection against pests, offering a longer lifespan than uncoated alternatives.

- Aviaries and Pet Enclosures: Provides a secure and visually unobtrusive barrier that is safe for animals.

3. Construction and Infrastructure

- Temporary and Permanent Site Fencing: For construction sites, offering security and delineation. Its reusability and resistance to construction debris make it cost-effective.

- Gabion Baskets: Used in retaining walls and erosion control structures, where the PVC coating protects the underlying steel from water and soil corrosion, enhancing the structural integrity and lifespan of the entire system.

- Reinforcement Mesh: In specific concrete applications where exposure to corrosive elements is a concern, prolonging the life of concrete structures.

4. Marine and Coastal Environments

- Docks and Harbors: For protective barriers, safety guards, and minor marine structures due to its exceptional resistance to saltwater corrosion.

- Coastal Erosion Control: In lightweight applications where resistance to salt spray and UV is critical.

5. Landscaping and Architectural Elements

- Garden Fencing and Trellises: Provides a durable, low-maintenance solution that integrates well with natural surroundings.

- Decorative Panels: Used in modern architectural designs for aesthetic appeal, providing privacy screens or partitioning elements with long-lasting color and finish.

The versatility of pvc coated wire mesh panels demonstrates its adaptability to a wide array of functional and environmental demands, making it a highly valuable material across diverse industries.

Technical Advantages of PVC Coated Wire Mesh

The engineering advantages of pvc coated wire mesh over traditional fencing materials, particularly plain galvanized steel, are substantial and contribute significantly to its lower total cost of ownership and superior performance in demanding applications.

-

Superior Corrosion Resistance:

The primary advantage of PVC coating is its exceptional barrier protection against corrosive elements. Unlike galvanized steel, which relies on a sacrificial zinc layer that eventually degrades, PVC forms an impermeable shield. This makes it ideal for environments exposed to moisture, chemicals (e.g., acid rain, industrial fumes), saline conditions (coastal areas), and harsh weather. This translates to significantly extended service life, often 2-3 times longer than hot-dip galvanized mesh, minimizing replacement cycles and associated labor costs.

-

UV Stability and Color Retention:

High-quality PVC formulations include UV inhibitors that resist degradation from prolonged sunlight exposure. This ensures that the material retains its color and structural integrity without becoming brittle or faded, maintaining aesthetic appeal and performance over decades, a crucial factor for visible installations and long-term infrastructure.

-

Enhanced Aesthetics and Blending Capabilities:

Available in a wide range of RAL colors (most commonly green, black, grey), pvc coated wire mesh can be selected to blend seamlessly into natural landscapes or specific architectural designs. This aesthetic versatility is highly valued in public spaces, residential areas, and corporate campuses, where visual impact is as important as functionality.

-

Reduced Maintenance Requirements:

Due to its corrosion resistance and color stability, PVC coated mesh requires minimal maintenance. It does not need painting, recoating, or frequent rust removal, leading to substantial savings in labor and material costs over its lifetime. Simple cleaning is usually sufficient to maintain its appearance.

-

Smooth, Safe Surface:

The smooth, uniform PVC layer eliminates sharp edges, burrs, or wire ends that are common with uncoated or poorly galvanized mesh. This makes it safer for handling, installation, and interaction, particularly in public areas, schools, and animal enclosures, minimizing the risk of injury.

-

Electrical Insulation & Thermal Properties:

PVC is an excellent electrical insulator, which can be an advantage in specific industrial settings where accidental contact with electrified components needs to be prevented. While not primarily a thermal insulator for buildings, its low thermal conductivity can contribute to minor energy saving benefits in certain niche applications compared to bare metal.

These combined technical advantages underscore why pvc coated wire mesh is a strategic investment for projects requiring long-term durability, minimal upkeep, and reliable performance in challenging environments.

Vendor Comparison: Selecting the Right PVC Coated Wire Mesh Manufacturers

Choosing the right supplier for pvc coated wire mesh is a critical decision for any B2B project. The quality of the product, reliability of service, and capacity for customization can significantly impact project timelines, budget, and long-term performance. Here’s a framework for comparing pvc coated wire mesh manufacturers.

Key Evaluation Criteria:

- Quality Certifications & Standards: Verify ISO 9001 for quality management, CE certification for European markets, and adherence to ASTM, ANSI, or specific regional standards for materials and processes.

- Manufacturing Expertise & Technology: Inquire about their coating process (fluidized bed vs. electrostatic spray), pre-treatment procedures, and quality control protocols. Experienced manufacturers typically have state-of-the-art equipment and deep technical knowledge.

- Product Range & Customization: Assess their ability to provide diverse mesh sizes, wire gauges, panel dimensions, and especially custom PVC colors and coating thicknesses to meet unique project specifications.

- Material Traceability: A reputable manufacturer will offer full traceability of raw materials (steel wire origin, PVC compound specifications), providing assurance of consistent quality.

- Lead Times & Logistics: Evaluate their production capacity and typical lead times for standard and custom orders. Their logistics network for timely delivery is also crucial for project scheduling.

- Warranty & After-Sales Support: Understand their product warranty terms (e.g., against coating delamination, premature degradation) and the level of technical and customer support offered post-purchase.

- References & Case Studies: Request references from past B2B clients and detailed case studies demonstrating their successful project deliveries in relevant sectors.

Product Comparison: PVC Coated vs. Hot-Dip Galvanized Wire Mesh

While hot-dip galvanized mesh offers robust corrosion protection, pvc coated wire mesh often presents a superior long-term value proposition, particularly when aesthetic, environmental, and extended lifespan considerations are paramount.

| Feature | PVC Coated Wire Mesh | Hot-Dip Galvanized Wire Mesh | Advantage Highlight |

|---|---|---|---|

| Corrosion Resistance | Excellent, especially in chemical/salt environments. Physical barrier. | Very Good, sacrificial zinc layer. | PVC Coated (Longer-term barrier) |

| Service Life | 15-25+ years (often 2-3x galvanized) | 5-15 years (depending on environment) | PVC Coated (Superior Longevity) |

| Aesthetics | Wide range of colors, smooth finish, UV stable. | Silvery-grey, can dull over time. No color options. | PVC Coated (Visual Appeal & Integration) |

| Maintenance | Very low (no painting, minimal cleaning). | Low initially, but eventually requires intervention. | PVC Coated (Lowest Lifetime Cost) |

| Safety (Touch) | Smooth, non-abrasive surface, less risk of injury. | Rougher surface, potential for sharp edges/zinc flakes. | PVC Coated (Enhanced User Safety) |

| Cost (Initial) | Higher initial investment. | Lower initial investment. | Galvanized (Lower Upfront) |

While initial costs for pvc coated wire mesh might be higher, its extended lifespan, reduced maintenance, and superior aesthetic performance often lead to a lower total cost of ownership (TCO) over the project's duration.

Customized Solutions for PVC Coated Wire Mesh Panels

In the B2B sector, cookie-cutter solutions rarely suffice. Many industrial, architectural, and security projects demand highly specific parameters to ensure optimal performance, aesthetic integration, and compliance with unique site requirements. Recognizing this, leading pvc coated wire mesh manufacturers offer extensive customization capabilities.

Tailoring Dimensions and Specifications:

- Mesh Aperture: Custom mesh opening sizes can be produced to meet specific security levels, animal containment requirements, or filtration needs. For example, smaller apertures for rodent control, larger for visibility.

- Wire Gauge: The core steel wire diameter can be adjusted to achieve desired levels of rigidity, strength, and security. Heavier gauges provide greater resistance to cutting and bending.

- Panel/Roll Dimensions: While standard rolls and panels are available, custom lengths, widths, and heights are crucial for seamless integration into complex site layouts, reducing waste and installation time.

- PVC Coating Thickness: For extremely harsh environments (e.g., highly corrosive industrial zones, intense UV regions), a thicker PVC coating can be applied to provide enhanced protection and extended service life.

Color Matching and Aesthetic Integration:

- Custom RAL Colors: Beyond standard green, black, and grey, manufacturers can match virtually any RAL color specification to align with corporate branding, local architectural guidelines, or environmental blending requirements.

- Finish Options: While generally smooth, specific finishes or textures can sometimes be achieved for unique aesthetic or anti-climb properties.

Value-Added Services:

- Design Consultation: Expert teams work with clients to optimize mesh specifications based on project drawings, environmental factors, and budget constraints, ensuring the most suitable pvc coated wire mesh panels are selected.

- Prototyping: For large-scale or highly specialized projects, prototyping services allow clients to evaluate custom samples before full production, minimizing risks and ensuring satisfaction.

- Integrated Solutions: Many manufacturers can provide complementary accessories such as posts, gates, and specialized fasteners that are also PVC coated for a complete, uniform, and long-lasting system.

By leveraging customized solutions, businesses can procure pvc coated wire mesh that is precisely engineered for their unique challenges, ensuring maximum efficiency, longevity, and return on investment.

Application Case Studies: PVC Coated Wire Mesh in Action

Real-world applications demonstrate the tangible benefits and reliability of pvc coated wire mesh in diverse and demanding environments. These case studies highlight its performance and value proposition.

Case Study 1: Perimeter Security for a Coastal Petrochemical Plant

- Challenge: A major petrochemical facility located on a highly corrosive coastal site required robust, long-lasting perimeter fencing capable of resisting saltwater spray, industrial chemical fumes, and providing high security against intrusion. Traditional galvanized fencing showed rapid degradation.

- Solution: Installation of heavy-gauge PVC Coated Welded Wire Mesh fencing, specifically designed with an increased PVC coating thickness (0.8mm) to withstand extreme conditions. The mesh panels were paired with PVC-coated posts and fittings for a fully integrated protective system.

- Outcome: After 10 years, the PVC coated fencing showed negligible signs of corrosion or UV degradation, vastly outperforming the previous galvanized fence which required replacement within 3-5 years. The initial higher investment was offset by zero maintenance costs and extended lifespan, resulting in an estimated 40% reduction in TCO over two decades.

Case Study 2: Animal Enclosures for a Public Zoological Park

- Challenge: A metropolitan zoo needed to upgrade multiple animal enclosures, requiring a mesh material that was safe for animals (no sharp edges), highly durable against animal wear and tear, resistant to waste products, and aesthetically pleasing for public viewing areas.

- Solution: Custom-fabricated PVC Coated Welded Wire Mesh panels with specific mesh apertures were chosen. The smooth PVC coating prevented abrasions to animals, while its resistance to urine and feces extended the enclosure's cleanliness and lifespan. A dark green PVC color was selected to blend naturally with the park's landscaping.

- Outcome: The new enclosures provided a safe, secure, and visually appealing habitat for the animals. Zookeepers reported improved hygiene due to the easy-to-clean surface, and the durable PVC coating resisted damage from animal activity for over 15 years without significant wear, reducing maintenance and replacement costs.

Case Study 3: Erosion Control Gabion Walls in a Riverine Project

- Challenge: A civil engineering firm required robust gabion baskets for erosion control along a riverbank susceptible to fluctuating water levels and sediment abrasion. The material needed to withstand constant moisture, soil contact, and provide long-term structural stability.

- Solution: Gabion baskets constructed from heavy-duty pvc coated wire mesh were deployed. The PVC coating provided an additional layer of protection against water corrosion, chemical interactions from soil, and mechanical abrasion from moving sediments, complementing the inherent strength of the steel wire.

- Outcome: The PVC coated gabion structures demonstrated exceptional stability and durability, effectively preventing further riverbank erosion. Inspections after five years showed the mesh integrity to be completely intact, with no signs of rust or coating failure, ensuring the long-term effectiveness of the riverine stabilization project.

Ensuring Trust: Quality Assurance, Logistics, and Support

For B2B procurement, trust is built on a foundation of verifiable quality, transparent logistics, and unwavering customer support. Leading providers of pvc coated wire mesh prioritize these elements to ensure customer satisfaction and long-term partnerships.

Authoritativeness and Certifications:

- ISO 9001 Certification: Demonstrates a commitment to a robust quality management system, ensuring consistent product quality from raw material to finished good.

- CE Marking: For products intended for the European market, indicating compliance with essential health and safety requirements.

- Industry Affiliations: Membership in relevant industry associations (e.g., fence manufacturers' associations, construction material bodies) signifies adherence to industry best practices and standards.

- Years of Service & Client Portfolio: A long operational history and a track record of serving reputable clients across various industries (e.g., major petrochemical, infrastructure, governmental bodies) validates expertise and reliability.

- Independent Test Data: Providing third-party verified test reports for corrosion resistance (ASTM B117), UV stability (ASTM G154), and material strength (ASTM A641) builds confidence in product claims.

Lead Time & Fulfillment:

Efficient project planning relies on predictable lead times. For standard pvc coated wire mesh panels, typical lead times can range from 2-4 weeks. Customized orders, depending on complexity and volume, may require 4-8 weeks. We maintain robust production schedules and collaborate with reliable logistics partners to ensure on-time delivery. We provide transparent communication on order status and shipping details throughout the fulfillment process, from order confirmation to final delivery at your site.

Warranty Commitments:

Our pvc coated wire mesh products are backed by a comprehensive warranty, typically covering defects in materials and workmanship for a period of 5 to 10 years, depending on the product line and specific application environment. This warranty ensures protection against premature rusting, coating delamination, and significant UV degradation under normal operating conditions, providing peace of mind for your investment. Specific warranty details are available upon request and tailored to project specifications.

Customer Support & Technical Assistance:

Our commitment extends beyond product delivery. We offer dedicated customer support and technical assistance from initial consultation through installation and post-purchase. This includes:

- Expert Consultation: Guidance on material selection, technical specifications, and custom design to meet precise project needs.

- Installation Support: Providing best practice guidelines and technical drawings for efficient and correct installation.

- After-Sales Service: Responsive support for any queries, maintenance advice, or warranty claims. Our team is accessible via phone, email, and dedicated online portals.

Frequently Asked Questions (FAQ) about PVC Coated Wire Mesh

- Q1: What is the primary advantage of PVC coated wire mesh over galvanized mesh?

- A1: The primary advantage is superior corrosion resistance, especially in harsh environments (coastal, chemical). The PVC coating creates an impermeable barrier that protects the underlying steel from elements that would degrade zinc galvanization over time. It also offers a wider range of colors and a smoother, safer surface.

- Q2: How long does PVC coated wire mesh typically last?

- A2: Properly manufactured and installed pvc coated wire mesh has an excellent service life, typically ranging from 15 to 25 years or even longer, depending on the coating thickness, quality of the PVC compound, and environmental conditions.

- Q3: Is the PVC coating environmentally friendly?

- A3: Modern PVC formulations used in wire mesh are increasingly designed to be phthalate-free and lead-free, adhering to international environmental and health standards. The long lifespan of pvc coated wire mesh also reduces the frequency of replacement and associated resource consumption.

- Q4: Can PVC coated wire mesh be cut or modified on site?

- A4: Yes, it can be cut using standard wire cutters or angle grinders. However, it is important to apply a protective coating (e.g., touch-up paint specifically designed for PVC coatings) to any exposed cut ends to maintain the corrosion resistance of the underlying steel wire.

- Q5: What are the common applications for PVC coated wire mesh panels?

- A5: Common applications include perimeter security fencing for industrial and commercial sites, animal enclosures (zoos, farms), garden and landscaping barriers, gabion baskets for erosion control, and safety guards in various manufacturing settings due to its durability, aesthetics, and resistance to environmental factors.

- Q6: How does the coating thickness impact performance?

- A6: A thicker PVC coating generally provides enhanced protection, particularly against abrasion, impact, and prolonged exposure to corrosive elements or harsh UV radiation. It directly contributes to a longer product lifespan and greater durability.

References

- American Society for Testing and Materials (ASTM) Standards for Wire and Wire Products. ASTM International, West Conshohocken, PA.

- International Organization for Standardization (ISO) Standards for Quality Management and Corrosion Testing. ISO, Geneva, Switzerland.

- "Corrosion Protection by Polymer Coatings: Testing and Performance." Journal of Coatings Technology and Research, Volume 17, Issue 5, September 2020, pp. 1201–1215.

- "Polyvinyl Chloride (PVC) in Construction: An Environmental Product Declaration." The European Council of Vinyl Manufacturers (ECVM), Brussels, Belgium.

- "Advanced Materials for Infrastructure Protection." National Academies of Sciences, Engineering, and Medicine. The National Academies Press, Washington, DC.

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025