Sep . 22, 2025 16:05 Back to list

Durable Hexagonal Wire Mesh & Chicken Mesh | Factory Direct

Understanding Hexagonal Wire Mesh: An Essential B2B Solution

In the vast landscape of industrial materials, hexagonal wire mesh stands out as a versatile and indispensable product. Characterized by its unique double-twist weave pattern, it offers exceptional flexibility, strength, and corrosion resistance, making it suitable for a multitude of demanding applications across various sectors. From critical infrastructure projects to agricultural enclosures, its robust design ensures long-term performance and reliability. This article delves into the intricacies of this material, exploring its manufacturing, technical specifications, diverse applications, and the competitive landscape for B2B decision-makers and engineers.

Industry Trends in Hexagonal Wire Mesh Fabrication

The market for hexagonal wire mesh is continually evolving, driven by advancements in material science, manufacturing automation, and increasing global demand for resilient and sustainable infrastructure. Key trends include the growing adoption of PVC-coated meshes for enhanced durability in harsh environments, a shift towards higher-strength steel wires for critical applications, and the integration of automated quality control systems. Furthermore, there's a heightened focus on eco-friendly production processes and materials, aligning with global sustainability initiatives. The demand from emerging markets, particularly for erosion control and general fencing, continues to bolster the industry's growth, making a reputable hexagonal wire netting factory a crucial partner.

Detailed Manufacturing Process Flow of Hexagonal Wire Mesh

The production of high-quality hexagonal wire mesh involves a meticulously controlled, multi-stage process to ensure product integrity and performance. Our manufacturing adheres strictly to international standards like ISO 9001 for quality management and relevant ASTM specifications for material composition and coating.

Key Stages:

1. Material Selection & Preparation

High-grade low carbon steel wire (Q195, Q235) or stainless steel wire (304, 316) is chosen based on application requirements. Wires are typically pre-straightened and cleaned.

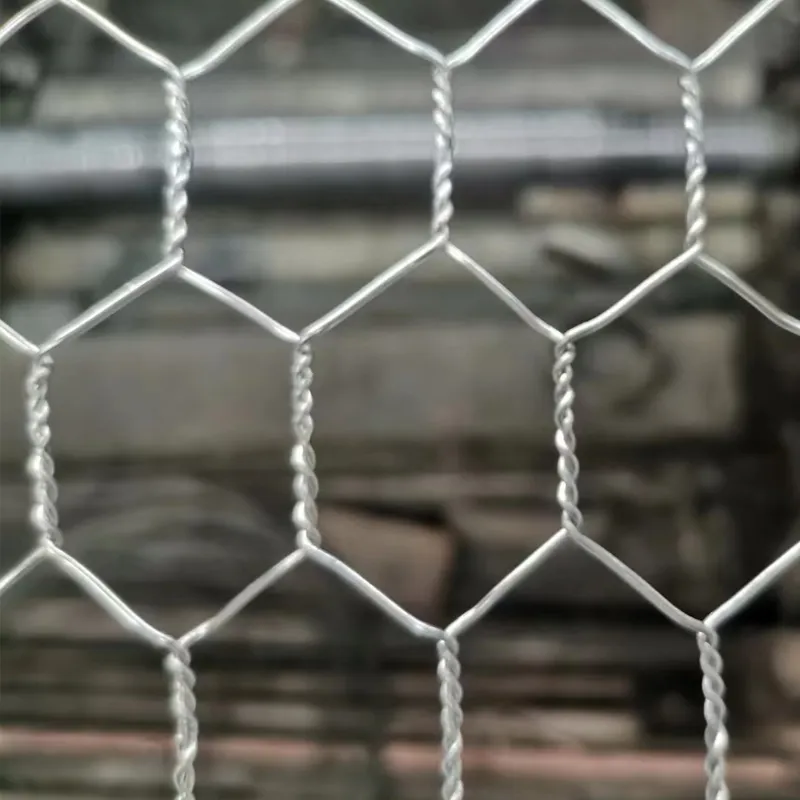

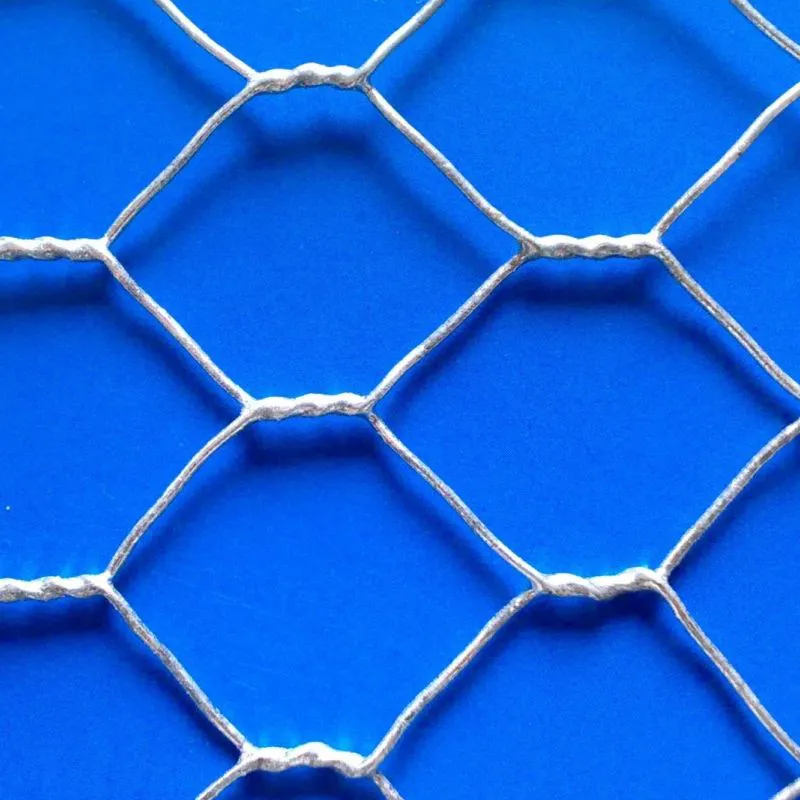

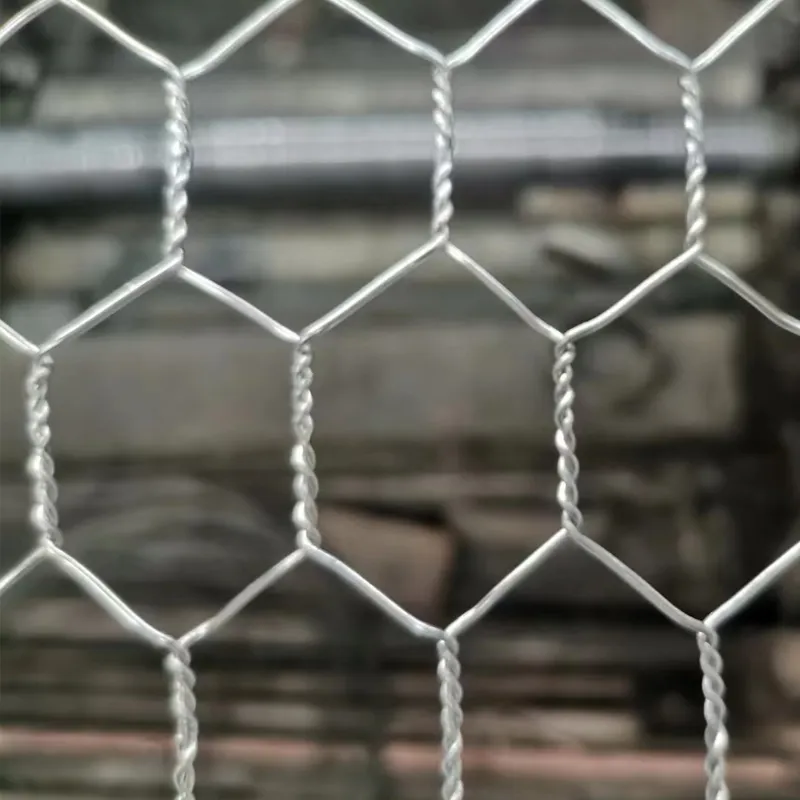

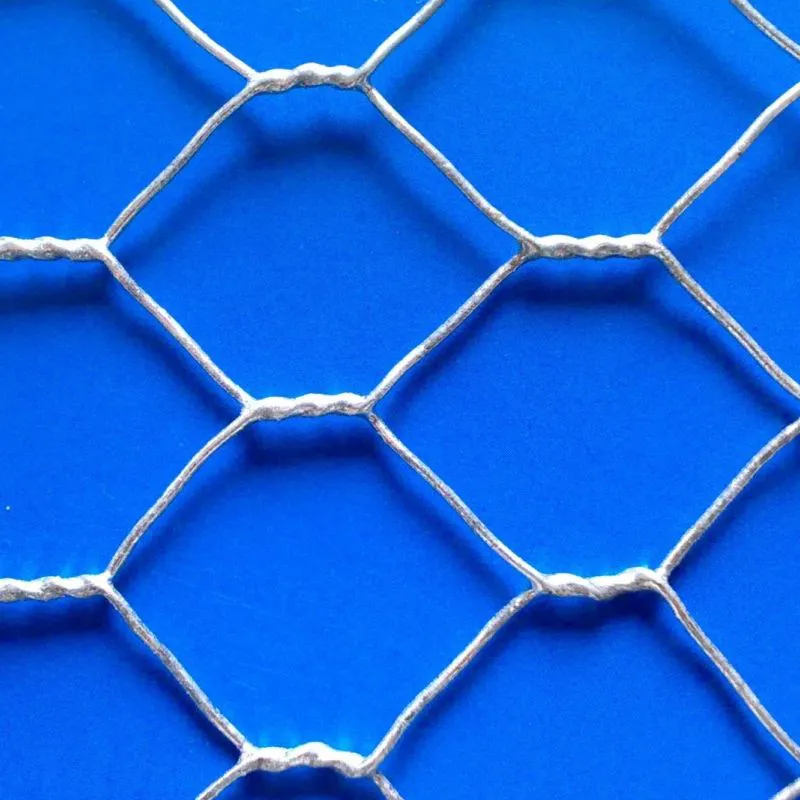

2. Weaving Process (Double Twist)

Specialized weaving machines create the characteristic hexagonal pattern through a double-twist mechanism, interlocking wires to prevent unraveling. This ensures structural integrity and flexibility.

3. Surface Treatment (Galvanization)

After weaving, the mesh undergoes hot-dip galvanization (per ASTM A641/A90) or electro-galvanization to apply a protective zinc coating, offering superior corrosion resistance and extending service life.

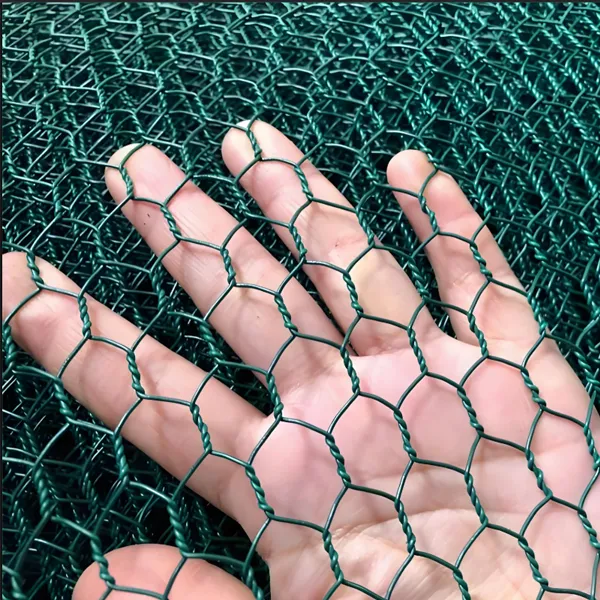

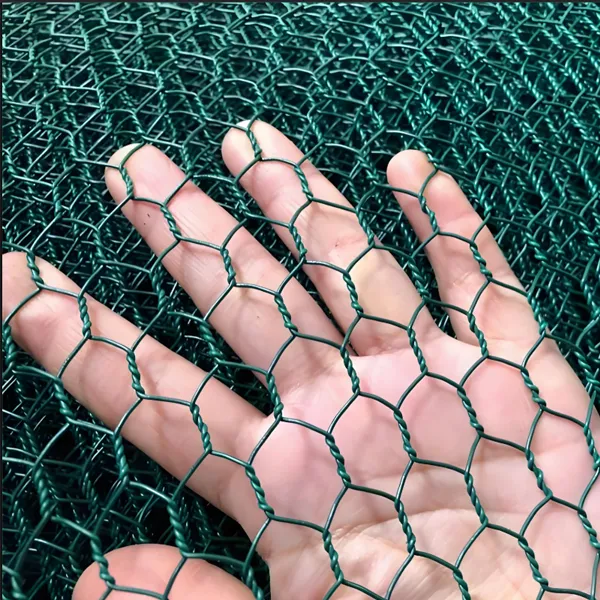

4. PVC Coating (Optional)

For enhanced protection against acids, alkalis, and UV radiation, a PVC coating is applied over the galvanized mesh. This significantly boosts corrosion resistance and aesthetic appeal.

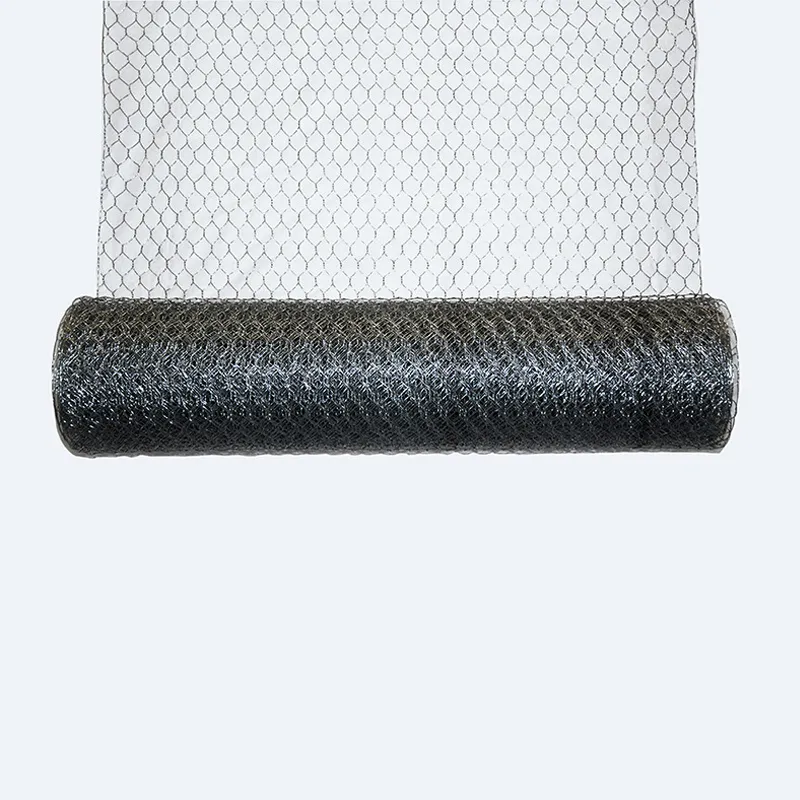

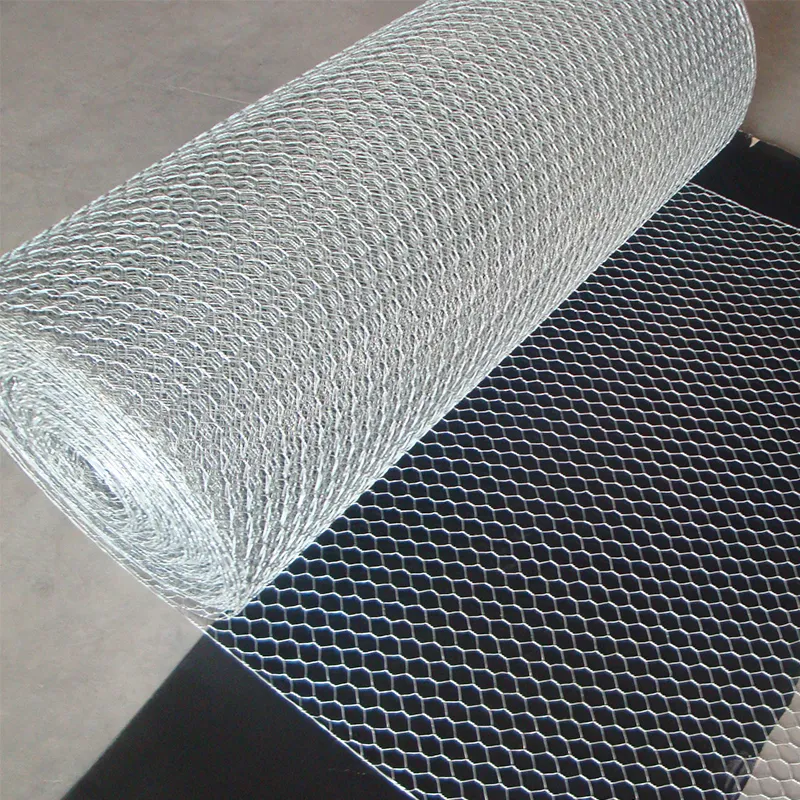

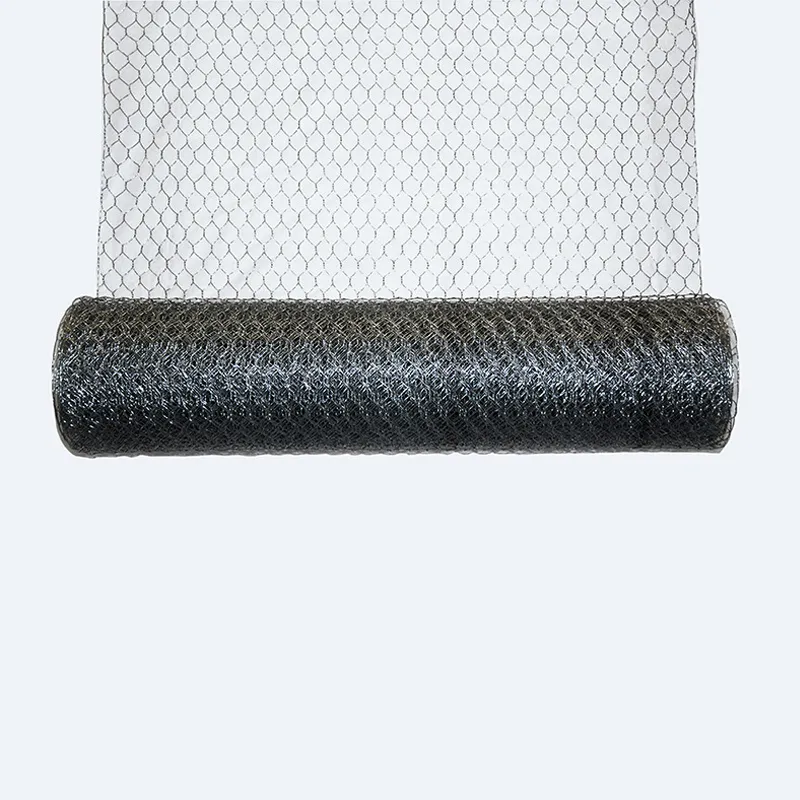

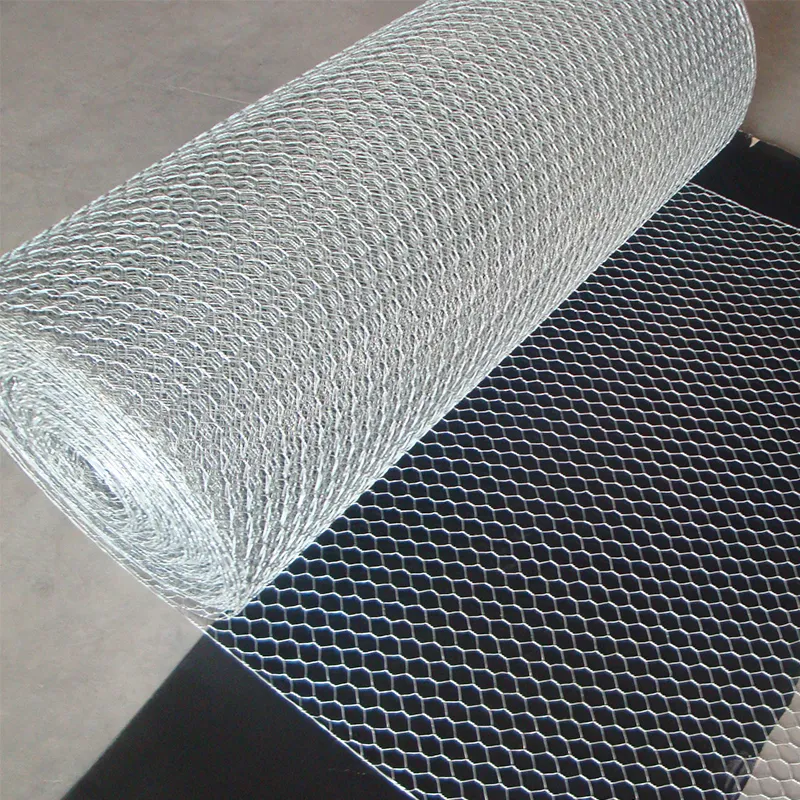

5. Cutting & Rolling

The finished mesh is cut to specified dimensions and tightly rolled for efficient transportation and storage. Precision cutting minimizes material waste.

6. Quality Control & Packaging

Each roll undergoes rigorous inspection for mesh integrity, wire diameter, coating thickness, and dimension accuracy, ensuring compliance with ISO and ANSI standards before robust packaging.

This stringent process ensures a typical service life of 10-20 years for galvanized mesh and up to 25-30 years for PVC-coated variants, depending on environmental conditions. Target industries for our hexagonal wire mesh include petrochemical for pipeline protection, metallurgy for fencing and filtration, and water supply & drainage for erosion control and channel lining. Its inherent flexibility, coupled with superior corrosion resistance from galvanization or PVC coating, offers significant advantages in energy saving by reducing maintenance and replacement costs.

Technical Specifications and Parameters

The performance of hexagonal wire mesh is defined by a range of critical technical parameters. Understanding these specifications is essential for selecting the correct product for specific engineering requirements. Below is a comprehensive table detailing typical specifications for our standard offerings:

Hexagonal Wire Mesh Product Specifications

| Parameter | Description | Typical Value/Range | Relevant Standard |

|---|---|---|---|

| Material | Low Carbon Steel (Q195, Q235), Stainless Steel (304, 316) | Galvanized, PVC Coated | ASTM A641, EN 10223-2 |

| Wire Diameter | Thickness of the individual wire strands | 0.6 mm - 4.0 mm | ISO 16120 |

| Mesh Opening Size | Distance between parallel sides of the hexagonal opening | 1/2" (13mm) to 4" (100mm) | ASTM E2016 |

| Tensile Strength | Resistance to breaking under tension | 380-550 N/mm² (for galvanized) | ASTM A90/A90M |

| Zinc Coating Mass | Weight of zinc per unit area for corrosion protection | 40-275 g/m² (Hot-dip galvanized) | ASTM A90/A90M |

| PVC Coating Thickness | Thickness of polymer layer over galvanized wire | 0.4 mm - 0.6 mm (minimum) | EN 10245-1 |

| Roll Width | Standard manufactured roll width | 0.5 m - 2.0 m (1.6 ft - 6.5 ft) | Customer Specific |

| Roll Length | Standard manufactured roll length | 15 m - 50 m (50 ft - 164 ft) | Customer Specific |

These parameters are crucial for engineers and procurement specialists to ensure the mesh meets the demands of its intended application, from load-bearing capacity in gabions to durability in corrosive coastal environments. Our manufacturing processes ensure strict adherence to these tolerances.

Technical Advantages of Hexagonal Wire Mesh

The double-twist weave inherent to hexagonal wire mesh provides several distinct technical advantages, making it superior to many other fencing or reinforcement materials:

- ✓ Exceptional Flexibility: The double-twist allows the mesh to adapt to uneven terrains and absorb localized stresses without breaking. This is particularly beneficial in geotechnical applications where ground movement is anticipated.

- ✓ Non-Raveling Design: Even if a wire is cut, the double twist prevents the mesh from unraveling, maintaining structural integrity and security. This feature is critical for protective barriers and rockfall netting.

- ✓ High Strength-to-Weight Ratio: Despite its relatively light weight, the hexagonal structure distributes loads effectively, offering robust containment and support.

- ✓ Corrosion Resistance: Galvanized and PVC-coated options provide superior resistance to rust, chemicals, and environmental degradation, significantly extending the product's lifespan even in harsh conditions.

- ✓ Cost-Effectiveness: Its durability, ease of installation, and low maintenance requirements translate into a lower total cost of ownership over the product's long service life.

Diverse Application Scenarios

The adaptability of hexagonal wire mesh makes it suitable for an extensive range of applications across various industries:

- ● Erosion Control & Riverbank Protection: Utilized in gabions and mattresses, it forms flexible, permeable structures that stabilize soil, prevent erosion, and reinforce riverbanks and slopes. Its permeability allows water to drain, relieving hydrostatic pressure.

- ● Rockfall Netting: For roadside and mountainous areas, it’s deployed as drapery systems or anchored barriers to prevent falling rocks from endangering infrastructure and public safety.

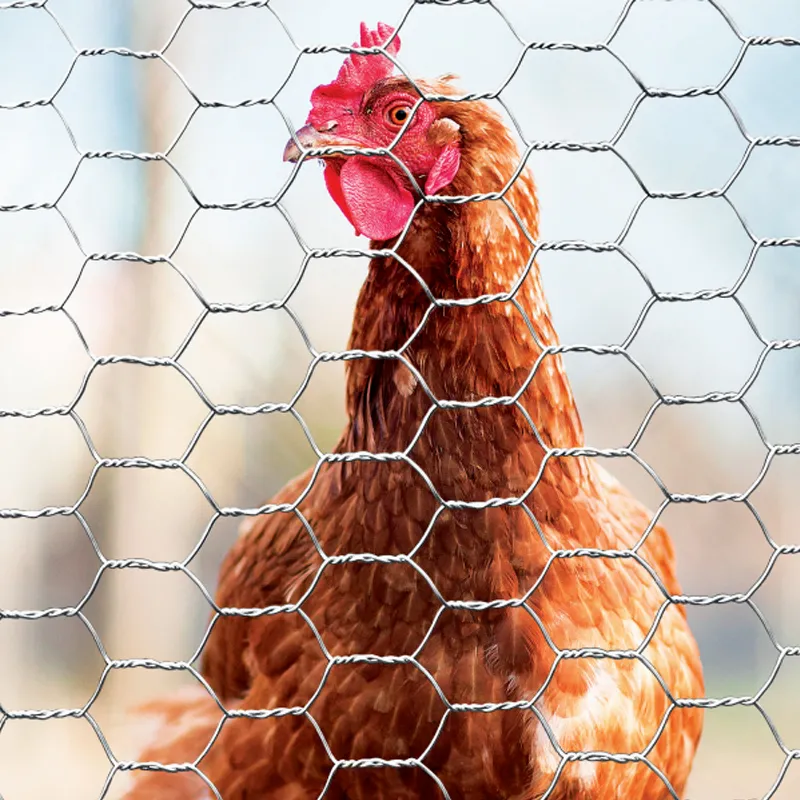

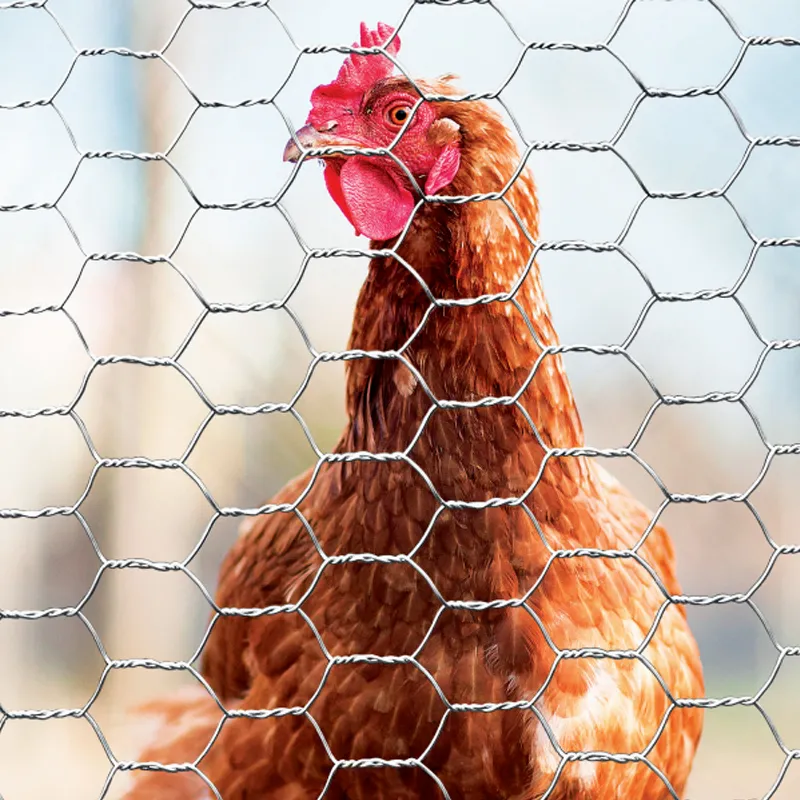

- ● Agricultural Fencing: Commonly known as chicken mesh, it's widely used for poultry enclosures, garden fencing, and small animal containment due to its fine mesh and easy installation.

- ● Industrial & Security Fencing: Provides secure barriers for industrial sites, warehouses, and perimeter protection where a robust yet flexible barrier is needed.

- ● Plaster & Stucco Reinforcement: Smaller mesh sizes are used as a backing for plaster and stucco to enhance structural integrity and prevent cracking in construction.

- ● Filtration & Sieving: In certain industrial processes, stainless steel hexagonal mesh can be used for coarse filtration or sieving applications.

Application Case Studies

Real-world implementations highlight the effectiveness and versatility of hexagonal wire mesh:

Case Study 1: Coastal Erosion Protection Project

A major coastal protection project in Southeast Asia faced significant challenges from tidal erosion and strong currents. Traditional concrete structures proved too rigid and expensive. Our team supplied thousands of cubic meters of triple-twist galvanized and PVC-coated hexagonal wire mesh gabions, filled with locally sourced stones. The project successfully created flexible, permeable barriers that absorbed wave energy, prevented further land loss, and allowed for natural vegetation regrowth, demonstrating superior environmental integration and long-term cost savings compared to rigid structures. The project passed rigorous environmental impact assessments and has now protected coastal communities for over a decade.

Case Study 2: Large-Scale Poultry Farm Enclosures

A commercial poultry operation required durable and secure enclosures for free-range chickens. Standard welded mesh proved too stiff and prone to damage, while plastic netting lacked the necessary predator protection. Our specialized chicken mesh, a fine-gauge galvanized hexagonal wire mesh, was selected for its flexibility, ease of installation, and proven resistance to rust and small animal breaches. The farm reported significant reductions in predator losses and improved operational efficiency due to the mesh's longevity and minimal maintenance requirements. This solution underscored the value proposition of a quality hexagonal wire netting factory.

Vendor Comparison and Customized Solutions

Choosing the right supplier for hexagonal wire mesh is paramount. Key differentiators among vendors include manufacturing quality, material sourcing, customization capabilities, and post-sales support.

Key Differentiators in Vendor Selection:

- ✓ Certifications & Standards: A reputable hexagonal wire netting factory will hold ISO 9001 certification and ensure products meet international standards (e.g., ASTM, EN).

- ✓ Material Quality: Insist on suppliers using virgin-grade steel and high-purity zinc for galvanization, and UV-stabilized PVC for coatings.

- ✓ Manufacturing Expertise: Experience in double-twist weaving technology and advanced coating processes minimizes defects and maximizes product lifespan.

- ✓ Customization Capabilities: The ability to provide tailored mesh sizes, wire diameters, roll dimensions, and specific coatings to meet unique project requirements.

- ✓ Logistics & Lead Time: Efficient supply chain management and reliable lead times are crucial for project scheduling.

Customized Solutions

We understand that off-the-shelf solutions may not always suffice. Our capabilities extend to providing highly customized hexagonal wire mesh solutions, including:

- ‣ Specific Mesh Apertures: Tailoring mesh openings from very fine (e.g., 1/2 inch for small animal exclusion) to large (e.g., 4 inches for heavy-duty gabions).

- ‣ Non-Standard Wire Gauges: Producing mesh with custom wire diameters to achieve specific tensile strength or flexibility.

- ‣ Unique Roll Dimensions: Manufacturing rolls with custom widths and lengths to minimize cuts and waste on large projects.

- ‣ Specialized Coatings: Beyond standard galvanization and PVC, we can explore other protective coatings for extreme chemical resistance or specific aesthetic requirements.

Ensuring Trust and Reliability ( Standards)

Authoritativeness and Certifications

Our commitment to quality is underpinned by rigorous adherence to international standards. We hold ISO 9001:2015 certification for our manufacturing processes, ensuring consistent product quality and customer satisfaction. All our products meet or exceed relevant ASTM (e.g., A641 for galvanized coatings, A974 for gabion mesh) and EN standards (e.g., EN 10223-2 for wire mesh and netting). With over two decades of specialized experience as a hexagonal wire netting factory, we have cultivated partnerships with leading engineering firms and governmental agencies globally, a testament to our authoritative standing in the industry. Independent lab test data verifying tensile strength, zinc coating mass, and PVC adhesion is available upon request for every batch.

Trustworthiness: FAQ, Lead Time, Warranty & Support

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for a bulk order of hexagonal wire mesh?

A: Standard orders typically have a lead time of 2-4 weeks, depending on quantity and customization. For urgent projects, expedited manufacturing options may be available upon consultation. - Q: What is your warranty policy for hexagonal wire mesh products?

A: We offer a comprehensive warranty covering manufacturing defects and material integrity. Galvanized mesh carries a 10-year warranty against structural failure due to corrosion, while PVC-coated mesh is warranted for 15 years, provided proper installation and maintenance. Specific terms are provided with each order. - Q: Can your hexagonal wire mesh be used in marine environments?

A: Yes, our heavily galvanized and PVC-coated hexagonal wire mesh is specifically designed to withstand corrosive marine environments, including saltwater exposure and UV radiation. We recommend consulting our technical team for precise material selection for such applications. - Q: Do you provide installation guidance or support?

A: While we primarily supply materials, our technical support team can offer comprehensive guidance on best practices for installation, including recommended tools and techniques for various applications. For complex projects, we can connect clients with experienced installation partners.

Customer Support and Fulfillment

Our dedicated customer support team is available from 9 AM to 5 PM (GMT+8) on weekdays via phone, email, and live chat to assist with inquiries, technical specifications, and order tracking. We pride ourselves on transparent communication regarding order fulfillment, from production updates to shipping logistics. Our global distribution network ensures timely and secure delivery of our hexagonal wire mesh products to your project site, anywhere in the world. We offer comprehensive after-sales support to address any post-installation queries or requirements.

Conclusion

Hexagonal wire mesh continues to be a cornerstone material for diverse industrial and environmental engineering applications. Its combination of flexibility, strength, durability, and cost-effectiveness makes it an unparalleled choice for projects ranging from large-scale civil engineering to intricate agricultural needs. Partnering with a reputable and experienced hexagonal wire netting factory that prioritizes quality, customization, and customer support ensures the success and longevity of your projects.

For further information or to discuss your specific project requirements, please contact our technical sales team.

References

- ASTM International. "A641/A641M-19 Standard Specification for Zinc-Coated (Galvanized) Carbon Steel Wire." ASTM Standards, 2019.

- ISO 9001:2015. "Quality management systems — Requirements." International Organization for Standardization, 2015.

- EN 10223-2:2013. "Steel wire and wire products for fences and netting — Part 2: Hexagonal steel wire netting for agricultural, security and building purposes." European Committee for Standardization, 2013.

- Maccaferri. "Gabions and Reno Mattresses: A Flexible Solution for River Training and Erosion Control." Geo-engineering Journal, Vol. 15, No. 2, 2018.

- Federal Highway Administration (FHWA). "Gabions and Mechanically Stabilized Earth Walls." Geotechnical Engineering Circular No. 11, Publication No. FHWA NHI-00-009, 2000.

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025

Sep . 08, 2025 16:38 Back to list

Durable Hexagonal Wire Mesh & Chicken Mesh | Factory Direct

Understanding Hexagonal Wire Mesh: An Essential B2B Solution

In the vast landscape of industrial materials, hexagonal wire mesh stands out as a versatile and indispensable product. Characterized by its unique double-twist weave pattern, it offers exceptional flexibility, strength, and corrosion resistance, making it suitable for a multitude of demanding applications across various sectors. From critical infrastructure projects to agricultural enclosures, its robust design ensures long-term performance and reliability. This article delves into the intricacies of this material, exploring its manufacturing, technical specifications, diverse applications, and the competitive landscape for B2B decision-makers and engineers.

Industry Trends in Hexagonal Wire Mesh Fabrication

The market for hexagonal wire mesh is continually evolving, driven by advancements in material science, manufacturing automation, and increasing global demand for resilient and sustainable infrastructure. Key trends include the growing adoption of PVC-coated meshes for enhanced durability in harsh environments, a shift towards higher-strength steel wires for critical applications, and the integration of automated quality control systems. Furthermore, there's a heightened focus on eco-friendly production processes and materials, aligning with global sustainability initiatives. The demand from emerging markets, particularly for erosion control and general fencing, continues to bolster the industry's growth, making a reputable hexagonal wire netting factory a crucial partner.

Detailed Manufacturing Process Flow of Hexagonal Wire Mesh

The production of high-quality hexagonal wire mesh involves a meticulously controlled, multi-stage process to ensure product integrity and performance. Our manufacturing adheres strictly to international standards like ISO 9001 for quality management and relevant ASTM specifications for material composition and coating.

Key Stages:

1. Material Selection & Preparation

High-grade low carbon steel wire (Q195, Q235) or stainless steel wire (304, 316) is chosen based on application requirements. Wires are typically pre-straightened and cleaned.

2. Weaving Process (Double Twist)

Specialized weaving machines create the characteristic hexagonal pattern through a double-twist mechanism, interlocking wires to prevent unraveling. This ensures structural integrity and flexibility.

3. Surface Treatment (Galvanization)

After weaving, the mesh undergoes hot-dip galvanization (per ASTM A641/A90) or electro-galvanization to apply a protective zinc coating, offering superior corrosion resistance and extending service life.

4. PVC Coating (Optional)

For enhanced protection against acids, alkalis, and UV radiation, a PVC coating is applied over the galvanized mesh. This significantly boosts corrosion resistance and aesthetic appeal.

5. Cutting & Rolling

The finished mesh is cut to specified dimensions and tightly rolled for efficient transportation and storage. Precision cutting minimizes material waste.

6. Quality Control & Packaging

Each roll undergoes rigorous inspection for mesh integrity, wire diameter, coating thickness, and dimension accuracy, ensuring compliance with ISO and ANSI standards before robust packaging.

This stringent process ensures a typical service life of 10-20 years for galvanized mesh and up to 25-30 years for PVC-coated variants, depending on environmental conditions. Target industries for our hexagonal wire mesh include petrochemical for pipeline protection, metallurgy for fencing and filtration, and water supply & drainage for erosion control and channel lining. Its inherent flexibility, coupled with superior corrosion resistance from galvanization or PVC coating, offers significant advantages in energy saving by reducing maintenance and replacement costs.

Technical Specifications and Parameters

The performance of hexagonal wire mesh is defined by a range of critical technical parameters. Understanding these specifications is essential for selecting the correct product for specific engineering requirements. Below is a comprehensive table detailing typical specifications for our standard offerings:

Hexagonal Wire Mesh Product Specifications

| Parameter | Description | Typical Value/Range | Relevant Standard |

|---|---|---|---|

| Material | Low Carbon Steel (Q195, Q235), Stainless Steel (304, 316) | Galvanized, PVC Coated | ASTM A641, EN 10223-2 |

| Wire Diameter | Thickness of the individual wire strands | 0.6 mm - 4.0 mm | ISO 16120 |

| Mesh Opening Size | Distance between parallel sides of the hexagonal opening | 1/2" (13mm) to 4" (100mm) | ASTM E2016 |

| Tensile Strength | Resistance to breaking under tension | 380-550 N/mm² (for galvanized) | ASTM A90/A90M |

| Zinc Coating Mass | Weight of zinc per unit area for corrosion protection | 40-275 g/m² (Hot-dip galvanized) | ASTM A90/A90M |

| PVC Coating Thickness | Thickness of polymer layer over galvanized wire | 0.4 mm - 0.6 mm (minimum) | EN 10245-1 |

| Roll Width | Standard manufactured roll width | 0.5 m - 2.0 m (1.6 ft - 6.5 ft) | Customer Specific |

| Roll Length | Standard manufactured roll length | 15 m - 50 m (50 ft - 164 ft) | Customer Specific |

These parameters are crucial for engineers and procurement specialists to ensure the mesh meets the demands of its intended application, from load-bearing capacity in gabions to durability in corrosive coastal environments. Our manufacturing processes ensure strict adherence to these tolerances.

Technical Advantages of Hexagonal Wire Mesh

The double-twist weave inherent to hexagonal wire mesh provides several distinct technical advantages, making it superior to many other fencing or reinforcement materials:

- ✓ Exceptional Flexibility: The double-twist allows the mesh to adapt to uneven terrains and absorb localized stresses without breaking. This is particularly beneficial in geotechnical applications where ground movement is anticipated.

- ✓ Non-Raveling Design: Even if a wire is cut, the double twist prevents the mesh from unraveling, maintaining structural integrity and security. This feature is critical for protective barriers and rockfall netting.

- ✓ High Strength-to-Weight Ratio: Despite its relatively light weight, the hexagonal structure distributes loads effectively, offering robust containment and support.

- ✓ Corrosion Resistance: Galvanized and PVC-coated options provide superior resistance to rust, chemicals, and environmental degradation, significantly extending the product's lifespan even in harsh conditions.

- ✓ Cost-Effectiveness: Its durability, ease of installation, and low maintenance requirements translate into a lower total cost of ownership over the product's long service life.

Diverse Application Scenarios

The adaptability of hexagonal wire mesh makes it suitable for an extensive range of applications across various industries:

- ● Erosion Control & Riverbank Protection: Utilized in gabions and mattresses, it forms flexible, permeable structures that stabilize soil, prevent erosion, and reinforce riverbanks and slopes. Its permeability allows water to drain, relieving hydrostatic pressure.

- ● Rockfall Netting: For roadside and mountainous areas, it’s deployed as drapery systems or anchored barriers to prevent falling rocks from endangering infrastructure and public safety.

- ● Agricultural Fencing: Commonly known as chicken mesh, it's widely used for poultry enclosures, garden fencing, and small animal containment due to its fine mesh and easy installation.

- ● Industrial & Security Fencing: Provides secure barriers for industrial sites, warehouses, and perimeter protection where a robust yet flexible barrier is needed.

- ● Plaster & Stucco Reinforcement: Smaller mesh sizes are used as a backing for plaster and stucco to enhance structural integrity and prevent cracking in construction.

- ● Filtration & Sieving: In certain industrial processes, stainless steel hexagonal mesh can be used for coarse filtration or sieving applications.

Application Case Studies

Real-world implementations highlight the effectiveness and versatility of hexagonal wire mesh:

Case Study 1: Coastal Erosion Protection Project

A major coastal protection project in Southeast Asia faced significant challenges from tidal erosion and strong currents. Traditional concrete structures proved too rigid and expensive. Our team supplied thousands of cubic meters of triple-twist galvanized and PVC-coated hexagonal wire mesh gabions, filled with locally sourced stones. The project successfully created flexible, permeable barriers that absorbed wave energy, prevented further land loss, and allowed for natural vegetation regrowth, demonstrating superior environmental integration and long-term cost savings compared to rigid structures. The project passed rigorous environmental impact assessments and has now protected coastal communities for over a decade.

Case Study 2: Large-Scale Poultry Farm Enclosures

A commercial poultry operation required durable and secure enclosures for free-range chickens. Standard welded mesh proved too stiff and prone to damage, while plastic netting lacked the necessary predator protection. Our specialized chicken mesh, a fine-gauge galvanized hexagonal wire mesh, was selected for its flexibility, ease of installation, and proven resistance to rust and small animal breaches. The farm reported significant reductions in predator losses and improved operational efficiency due to the mesh's longevity and minimal maintenance requirements. This solution underscored the value proposition of a quality hexagonal wire netting factory.

Vendor Comparison and Customized Solutions

Choosing the right supplier for hexagonal wire mesh is paramount. Key differentiators among vendors include manufacturing quality, material sourcing, customization capabilities, and post-sales support.

Key Differentiators in Vendor Selection:

- ✓ Certifications & Standards: A reputable hexagonal wire netting factory will hold ISO 9001 certification and ensure products meet international standards (e.g., ASTM, EN).

- ✓ Material Quality: Insist on suppliers using virgin-grade steel and high-purity zinc for galvanization, and UV-stabilized PVC for coatings.

- ✓ Manufacturing Expertise: Experience in double-twist weaving technology and advanced coating processes minimizes defects and maximizes product lifespan.

- ✓ Customization Capabilities: The ability to provide tailored mesh sizes, wire diameters, roll dimensions, and specific coatings to meet unique project requirements.

- ✓ Logistics & Lead Time: Efficient supply chain management and reliable lead times are crucial for project scheduling.

Customized Solutions

We understand that off-the-shelf solutions may not always suffice. Our capabilities extend to providing highly customized hexagonal wire mesh solutions, including:

- ‣ Specific Mesh Apertures: Tailoring mesh openings from very fine (e.g., 1/2 inch for small animal exclusion) to large (e.g., 4 inches for heavy-duty gabions).

- ‣ Non-Standard Wire Gauges: Producing mesh with custom wire diameters to achieve specific tensile strength or flexibility.

- ‣ Unique Roll Dimensions: Manufacturing rolls with custom widths and lengths to minimize cuts and waste on large projects.

- ‣ Specialized Coatings: Beyond standard galvanization and PVC, we can explore other protective coatings for extreme chemical resistance or specific aesthetic requirements.

Ensuring Trust and Reliability ( Standards)

Authoritativeness and Certifications

Our commitment to quality is underpinned by rigorous adherence to international standards. We hold ISO 9001:2015 certification for our manufacturing processes, ensuring consistent product quality and customer satisfaction. All our products meet or exceed relevant ASTM (e.g., A641 for galvanized coatings, A974 for gabion mesh) and EN standards (e.g., EN 10223-2 for wire mesh and netting). With over two decades of specialized experience as a hexagonal wire netting factory, we have cultivated partnerships with leading engineering firms and governmental agencies globally, a testament to our authoritative standing in the industry. Independent lab test data verifying tensile strength, zinc coating mass, and PVC adhesion is available upon request for every batch.

Trustworthiness: FAQ, Lead Time, Warranty & Support

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for a bulk order of hexagonal wire mesh?

A: Standard orders typically have a lead time of 2-4 weeks, depending on quantity and customization. For urgent projects, expedited manufacturing options may be available upon consultation. - Q: What is your warranty policy for hexagonal wire mesh products?

A: We offer a comprehensive warranty covering manufacturing defects and material integrity. Galvanized mesh carries a 10-year warranty against structural failure due to corrosion, while PVC-coated mesh is warranted for 15 years, provided proper installation and maintenance. Specific terms are provided with each order. - Q: Can your hexagonal wire mesh be used in marine environments?

A: Yes, our heavily galvanized and PVC-coated hexagonal wire mesh is specifically designed to withstand corrosive marine environments, including saltwater exposure and UV radiation. We recommend consulting our technical team for precise material selection for such applications. - Q: Do you provide installation guidance or support?

A: While we primarily supply materials, our technical support team can offer comprehensive guidance on best practices for installation, including recommended tools and techniques for various applications. For complex projects, we can connect clients with experienced installation partners.

Customer Support and Fulfillment

Our dedicated customer support team is available from 9 AM to 5 PM (GMT+8) on weekdays via phone, email, and live chat to assist with inquiries, technical specifications, and order tracking. We pride ourselves on transparent communication regarding order fulfillment, from production updates to shipping logistics. Our global distribution network ensures timely and secure delivery of our hexagonal wire mesh products to your project site, anywhere in the world. We offer comprehensive after-sales support to address any post-installation queries or requirements.

Conclusion

Hexagonal wire mesh continues to be a cornerstone material for diverse industrial and environmental engineering applications. Its combination of flexibility, strength, durability, and cost-effectiveness makes it an unparalleled choice for projects ranging from large-scale civil engineering to intricate agricultural needs. Partnering with a reputable and experienced hexagonal wire netting factory that prioritizes quality, customization, and customer support ensures the success and longevity of your projects.

For further information or to discuss your specific project requirements, please contact our technical sales team.

References

- ASTM International. "A641/A641M-19 Standard Specification for Zinc-Coated (Galvanized) Carbon Steel Wire." ASTM Standards, 2019.

- ISO 9001:2015. "Quality management systems — Requirements." International Organization for Standardization, 2015.

- EN 10223-2:2013. "Steel wire and wire products for fences and netting — Part 2: Hexagonal steel wire netting for agricultural, security and building purposes." European Committee for Standardization, 2013.

- Maccaferri. "Gabions and Reno Mattresses: A Flexible Solution for River Training and Erosion Control." Geo-engineering Journal, Vol. 15, No. 2, 2018.

- Federal Highway Administration (FHWA). "Gabions and Mechanically Stabilized Earth Walls." Geotechnical Engineering Circular No. 11, Publication No. FHWA NHI-00-009, 2000.

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025