Sep . 23, 2025 02:05 Back to list

Durable Gabion Cages For Sale - Versatile Landscape Solutions

The Strategic Role of Gabion Solutions in Modern Infrastructure

In the landscape of modern civil engineering and environmental protection, the demand for robust, sustainable, and cost-effective solutions for erosion control, retaining structures, and hydraulic works is paramount. Among these, gabion cages for sale have emerged as an indispensable component. These versatile wire mesh container111s, filled with natural stone, offer an ideal blend of strength, flexibility, permeability, and ecological integration, making them a preferred choice for engineers, contractors, and governmental agencies worldwide.

This comprehensive overview delves into the critical aspects of gabion technology, from prevailing industry trends and meticulous manufacturing processes to technical specifications, diverse application scenarios, and the intrinsic advantages they offer. We aim to provide B2B decision-makers and technical professionals with the insights necessary to make informed procurement decisions, highlighting the expertise, experience, authoritativeness, and trustworthiness of leading gabion manufacturers.

Current Industry Trends in Gabion Technology

The gabion industry is continually evolving, driven by an increased emphasis on sustainability, resilience, and efficiency in construction. Key trends include:

- Eco-Engineering Integration: A growing focus on designs that foster vegetation growth within gabion structures, enhancing biodiversity and blending seamlessly with natural landscapes. This approach significantly contributes to ecological restoration projects.

- Advanced Corrosion Protection: While traditional galvanization remains popular, there's a surge in demand for materials with superior corrosion resistance, such as Galfan (Zn-5%Al-MM) alloy coatings and high-performance PVC coatings. These coatings extend the service life of gabion box structures, particularly in harsh environments like coastal areas or polluted industrial zones.

- Modular and Prefabricated Gabions: The adoption of pre-assembled or flat-packed gabions that allow for quicker on-site deployment, reducing labor costs and project timelines. This is particularly beneficial for large-scale infrastructure projects.

- Digital Design and Analysis: The use of advanced software for modeling gabion structure performance under various loads and environmental conditions, optimizing designs for stability and material efficiency.

- Increased Demand for Aesthetic Solutions: Beyond pure functionality, there's a rising interest in gabions for architectural and landscaping applications, demanding higher aesthetic standards and custom finishes.

These trends underscore the importance of partnering with a forward-thinking gabion box supplier who can deliver cutting-edge solutions.

The Manufacturing Process of High-Quality Gabion Cages

The production of durable and effective gabion cages for sale involves a precise sequence of steps, ensuring adherence to stringent international standards. Our process emphasizes material integrity, manufacturing precision, and rigorous quality control.

Schematic Steps of Production:

- Material Selection and Wire Drawing: We begin with high-grade steel wire rods, typically low-carbon steel, chosen for their optimal tensile strength and ductility. These rods undergo cold drawing to achieve the precise wire diameters required for gabion mesh, ranging from 2.0 mm to 4.0 mm.

-

Weaving/Welding Process:

- Double-Twisted Hexagonal Mesh (Gabion Box): For traditional gabion boxes, wires are continuously twisted together to form a double-twisted hexagonal mesh. This method ensures exceptional strength, flexibility, and prevents unraveling even if a wire is cut. Our state-of-the-art weaving machines operate with high precision.

- Welded Mesh Gabions: For welded mesh gabions, individual wires are resistance-welded at their intersections, forming a rigid, square, or rectangular mesh. This type is often preferred for architectural applications or where a more rigid structure is desired.

-

Surface Treatment (Corrosion Protection): This is a critical stage for the longevity of the gabion.

- Hot-Dip Galvanization: After weaving/welding, the wire mesh panels are hot-dip galvanized, forming a metallurgical bond between the zinc coating and the steel. This provides a robust barrier against corrosion. Coating weight typically ranges from 240 g/m² to 290 g/m².

- Galfan (Zn-5%Al-MM) Coating: A superior alternative, Galfan offers enhanced corrosion resistance compared to standard galvanization, especially in acidic or saline environments.

- PVC Coating: For highly corrosive environments (e.g., marine, polluted industrial areas), a thick layer of PVC (Polyvinyl Chloride) is extruded onto galvanized or Galfan-coated wire. This significantly extends the service life, often exceeding 75-100 years. The PVC coating typically has a minimum thickness of 0.5 mm.

- Cutting and Edge Reinforcement: The treated wire mesh is cut to the specified dimensions for gabion panels (front, back, sides, top, base, and diaphragms). All external edges are reinforced with heavier selvedge wire to enhance structural integrity.

- Assembly and Packaging: The panels are then folded flat for efficient transport. Lacing wire or C-rings are included for on-site assembly. The flat-packed gabions are bundled, often strapped onto pallets, ready for shipment.

-

Quality Control and Testing Standards: Every batch undergoes rigorous quality checks. We adhere strictly to international standards such as ISO 9001:2015 for quality management, ASTM A975-97 for gabion basket specifications, and EN 10223-3 for metallic wire mesh products.

- Tensile Strength Testing: Ensuring the wire meets specified strength requirements (e.g., 380-550 N/mm²).

- Elongation Testing: Verifying wire ductility (typically >10%).

- Coating Thickness/Adhesion Tests: Ensuring uniform and durable anti-corrosion layers.

- Mesh Aperture and Dimension Checks: Guaranteeing correct sizing and tolerance.

This meticulous process ensures that our gabion cages for sale offer an extended service life, typically ranging from 25 years for heavily galvanized units to over 75-100 years for PVC-coated systems, even in challenging environments.

Technical Specifications and Parameters

Understanding the precise technical parameters is crucial for engineers and procurement specialists when evaluating gabion cages for sale. Here, we outline the key specifications that define our high-performance gabion products.

Typical Gabion Box Specifications

| Parameter | Description | Standard Values/Range |

|---|---|---|

| Mesh Type | Double-Twisted Hexagonal Mesh or Welded Mesh | ASTM A975-97, EN 10223-3 |

| Wire Diameter | Main Mesh Wire, Selvedge Wire, Lacing Wire | 2.0 mm - 4.0 mm (Mesh); 3.0 mm - 5.0 mm (Selvedge); 2.2 mm (Lacing) |

| Mesh Aperture (Opening) | Typically hexagonal or square openings | 60x80 mm, 80x100 mm, 100x120 mm (Hexagonal); 50x50 mm, 75x75 mm (Welded) |

| Tensile Strength | Of the wire material | Min. 380 N/mm² (typically 380-550 N/mm²) |

| Elongation | At break for wire | Min. 10% (for wire 3.0mm) |

| Corrosion Protection | Coating type and weight/thickness |

|

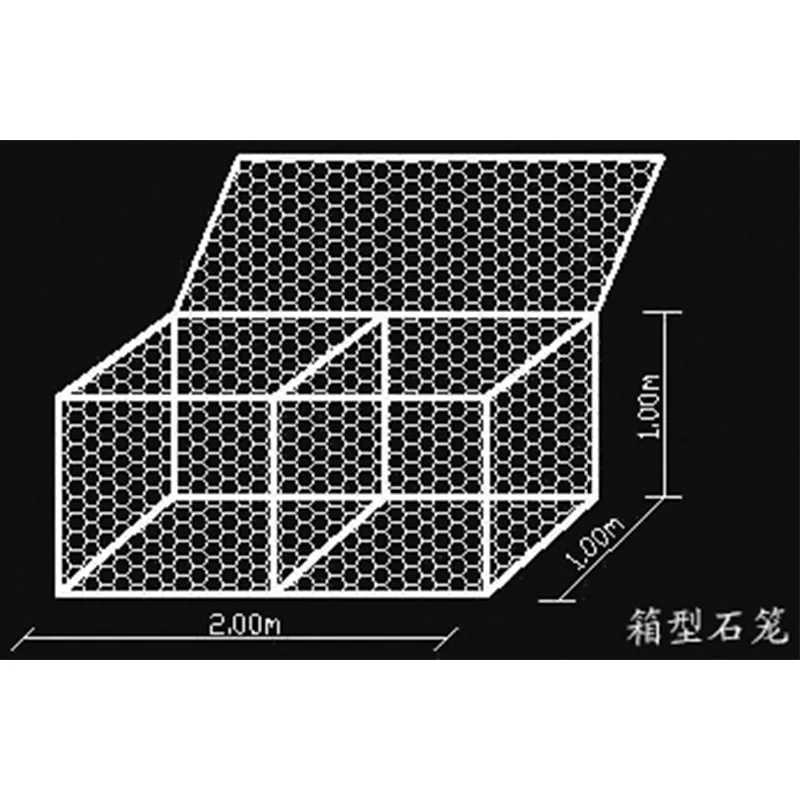

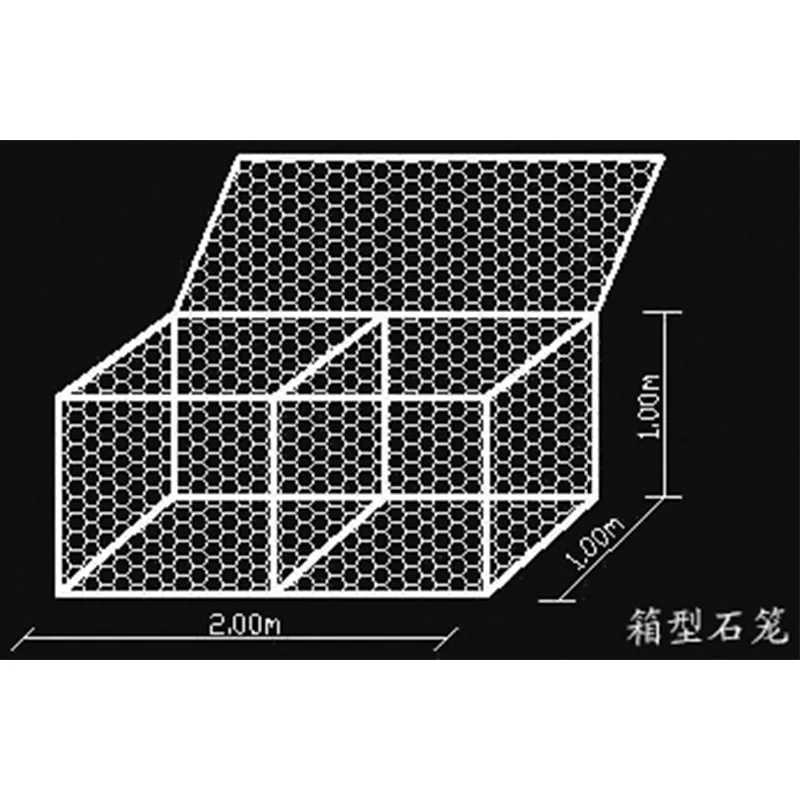

| Gabion Dimensions (L x W x H) | Standard sizes available, customizable |

|

| Diaphragms | Internal partitions for structural stability and shape retention | Included at 1.0m intervals for gabions longer than 2.0m |

Diverse Application Scenarios and Case Studies

The versatility of gabion box structures makes them suitable for a vast array of engineering challenges across various sectors. Their adaptability to site conditions, along with their aesthetic and environmental benefits, underscores their value.

Typical Application Scenarios:

- Retaining Walls: Gabion walls are gravity structures used to stabilize slopes, support road embankments, or create tiered landscaping. Their flexibility allows them to settle and deform without structural failure, unlike rigid concrete walls. In a recent highway expansion project in the mountainous regions of [Client Region], our high-strength gabion cages for sale were instrumental in constructing a 15-meter high retaining wall, providing superior seismic resilience.

- Erosion Control and River Training: Gabions are extensively used in hydraulic engineering for river bank protection, channel lining, weirs, and scour protection. Their permeability allows for hydrostatic pressure relief, preventing uplift and ensuring stability. For the [River Name] flood control initiative, over 5,000 cubic meters of our Galfan-coated gabion box units were deployed to stabilize critically eroded banks, demonstrating exceptional resistance to hydraulic forces.

- Bridge Abutments and Culvert Protection: Providing robust and flexible support for bridge structures and protecting culvert inlets/outlets from scour. Their ability to integrate with natural ground conditions is a key advantage.

- Coastal Protection Works: In coastal environments, gabions are used in revetments, groynes, and breakwaters to mitigate wave energy and protect against erosion. The PVC-coated gabion cages for sale are particularly suited for these saline conditions, offering superior longevity.

- Landscaping and Architectural Features: Beyond their engineering function, gabions are increasingly utilized in urban and commercial landscaping for aesthetically pleasing walls, seating, and decorative elements. The natural stone infill offers a unique textural appeal.

- Noise Barriers: When filled with suitable aggregate, gabion walls can effectively attenuate noise, making them ideal for highway and railway corridors.

Case Study: Landslide Remediation in [Specific Region, e.g., Pacific Northwest]

Following a series of intense rainfalls, a significant landslide threatened critical infrastructure along a major transportation route. Traditional concrete solutions were deemed too rigid and costly for the unstable geology. Our team, acting as a reliable gabion box supplier, provided a comprehensive gabion retaining wall system. We supplied 3,500 linear meters of PVC-coated gabions, filled with locally sourced rock. The project, completed within a tight 6-week schedule, demonstrated gabions' ability to:

- Adapt to Ground Movement: The inherent flexibility accommodated minor ground shifts without failure.

- Drain Effectively: The permeable structure prevented hydrostatic pressure buildup behind the wall.

- Minimize Environmental Impact: Utilization of local fill reduced transportation costs and carbon footprint.

Technical Advantages of Modern Gabion Cages

The selection of gabion cages for sale is often driven by a compelling set of technical and environmental advantages over conventional construction methods.

- Flexibility and Adaptability: Unlike rigid structures, gabions can tolerate differential settlement without loss of structural integrity. This makes them ideal for use on unstable or soft ground conditions, as well as in seismically active zones.

- Permeability and Drainage: The open mesh and stone fill allow for free drainage, preventing the buildup of hydrostatic pressure behind the structure. This eliminates the need for complex and costly drainage systems often required for concrete walls, contributing to energy saving in the overall project lifecycle.

- Durability and Longevity: With advanced coatings like Galfan and PVC, gabions offer exceptional corrosion resistance, ensuring a service life of 50-100 years. As vegetation grows through the structure, its strength and ecological value often increase over time.

- Environmental Friendliness: Gabions use natural, locally available rock fill, minimizing transportation costs and environmental impact. They also facilitate natural vegetation growth, promoting ecological integration and habitat creation.

- Cost-Effectiveness: Reduced material costs (especially with local fill), simpler construction techniques, and minimal need for heavy machinery often result in significant cost savings compared to traditional concrete or masonry structures. The rapid installation offered by a skilled gabion box supplier further contributes to project budget efficiency.

- Ease of Construction: Gabions are relatively simple to assemble and fill, requiring less skilled labor than concrete construction. This speeds up project completion, especially in remote areas.

Vendor Comparison: Choosing the Right Gabion Box Supplier

Selecting the optimal gabion box supplier is a strategic decision that impacts project success, longevity, and overall cost-efficiency. Here's a comparison framework to guide your choice when seeking gabion cages for sale.

Key Differentiators Among Gabion Suppliers:

| Feature | Competitor A (Price-Focused) | Competitor B (Mid-Range) | Yiszhe Wire Mesh (Premium B2B Solution) |

|---|---|---|---|

| Wire Material & Coating | Standard Galvanized (200 g/m²) | Heavy Galvanized (240 g/m²) | Heavy Galvanized (290 g/m²), Galfan, or PVC Coated (Min. 0.5mm) |

| Compliance & Certifications | Local standards only | Partial ASTM A975, no ISO | Full ASTM A975-97, EN 10223-3, ISO 9001:2015 certified production |

| Design & Engineering Support | Limited, basic guidance | Standard CAD support | Comprehensive technical consultation, custom design, site assessment assistance |

| Customization Capabilities | Standard sizes only | Limited size/mesh options | Full customization of dimensions, wire type, coating, mesh size, panel design |

| Lead Time for Large Orders | 4-6 weeks, inconsistent | 3-5 weeks | 2-4 weeks (streamlined production & logistics) |

| After-Sales Support & Warranty | No explicit warranty | 1-year material warranty | 10-year anti-corrosion warranty, 24/7 technical support |

| Experience & Reputation | Newer, few references | 5-10 years, regional projects | 20+ years, international projects, extensive client testimonials |

As a long-standing and reputable gabion box supplier, Yiszhe Wire Mesh consistently prioritizes product quality, technical support, and customer satisfaction, understanding that the initial investment in superior materials translates into long-term savings and project stability.

Customized Gabion Solutions

Recognizing that every engineering project presents unique challenges, we specialize in providing tailored gabion box solutions. Our expertise extends beyond standard product offerings to encompass comprehensive customization services, ensuring optimal performance for specific site conditions and design requirements.

- Dimensional Flexibility: We can manufacture gabions in non-standard lengths, widths, and heights to precisely fit project specifications, minimizing on-site cutting and waste. This includes custom basket sizes for complex architectural features or specific geological constraints.

- Material and Coating Variations: Depending on the environmental aggressivity (e.g., highly saline, acidic, or polluted sites), we offer a range of specialized coatings. This includes varying thicknesses of galvanization, specific Galfan alloy compositions, or custom PVC colors to match aesthetic requirements.

- Wire Gauge and Mesh Size Optimization: For structures requiring exceptional strength or specific hydraulic performance, we can adjust wire diameters and mesh apertures. Finer mesh can be used to retain smaller fill material or prevent sediment migration, while heavier gauge wire enhances structural robustness.

- Panel and Diaphragm Design: Custom internal diaphragm layouts can be designed for unusually shaped gabions or to provide additional internal stability for very tall structures. Specialized panel configurations are also available for unique applications like gabion mattresses or stepped walls.

- Technical Consultation and Design Assistance: Our engineering team collaborates closely with clients to review project blueprints, analyze site conditions, and recommend the most suitable gabion design. This includes providing CAD drawings and structural analysis to ensure compliance and optimize performance.

This commitment to customized solutions solidifies our position as a leading gabion box supplier capable of handling the most demanding infrastructure and environmental projects.

Ensuring Quality, Authoritativeness, and Trustworthiness

As a professional gabion box supplier, our commitment to quality, industry standards, and customer satisfaction is paramount. We consistently uphold the highest benchmarks to ensure that our gabion cages for sale not only meet but exceed client expectations and regulatory requirements.

Certifications and Compliance:

- ISO 9001:2015 Certified: Our manufacturing processes are globally recognized for adhering to the highest quality management systems, ensuring consistent product excellence.

- ASTM A975-97 Compliance: All our gabion products rigorously comply with the "Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Steel Wire or Metallic-Coated Steel Wire With PVC Coating) for Civil Engineering Purposes."

- EN 10223-3 and EN 10244-2 Adherence: European standards for metallic wire mesh and metallic coatings are strictly followed, guaranteeing performance and material quality.

- Third-Party Audits: Regular independent audits confirm our production integrity and product specifications.

Partner Clients and Years of Service:

With over two decades of specialized experience, we have proudly served a diverse portfolio of clients, including major governmental agencies, large-scale construction firms, and international infrastructure developers. Our long-term partnerships with clients across various industries, from water resource management to urban development, underscore our reliability and expertise. We have contributed to significant projects in the petrochemical, metallurgy, and water supply & drainage sectors, proving the adaptability and resilience of our gabion box solutions.

Test Data and Quality Assurance:

Each production batch undergoes comprehensive laboratory testing, including tensile strength tests, elongation tests, coating thickness measurements, and salt spray tests for corrosion resistance. This data is meticulously recorded and available for client review, providing transparent proof of product quality.

Customer Experience and Support

Our dedication to client success extends beyond product delivery. We believe in providing a seamless customer experience from initial consultation to post-installation support for all our gabion cages for sale.

Frequently Asked Questions (FAQ):

- Q1: What is the typical lead time for a large order of gabions?

- A1: Our standard lead time for significant bulk orders ranges from 2 to 4 weeks, depending on customization requirements and current production schedules. Expedited options are available upon request for urgent projects.

- Q2: What kind of warranty do you offer on your gabion products?

- A2: We provide a comprehensive 10-year anti-corrosion warranty on our galvanized and Galfan-coated gabions, and an extended warranty for PVC-coated products, covering material and manufacturing defects. Specific terms are outlined in our product documentation.

- Q3: Can you assist with the design and engineering of gabion structures?

- A3: Absolutely. Our experienced engineering team offers extensive design support, including technical consultations, structural analysis, CAD drawings, and recommendations for optimal gabion configurations tailored to your project's specific geological and hydraulic conditions.

- Q4: What are the primary advantages of Galfan coating over standard galvanization?

- A4: Galfan (Zn-5%Al-MM) offers significantly superior corrosion resistance, often 2-3 times that of traditional hot-dip galvanization. This is due to the presence of aluminum, which forms a more stable and protective passive layer, making it ideal for aggressive environments.

Lead Time and Fulfillment:

Our advanced manufacturing capabilities and robust supply chain management enable efficient order processing and timely delivery. We work closely with our logistics partners to ensure prompt and secure shipment of gabion cages for sale to project sites globally, adhering to agreed-upon schedules to support your project timelines effectively.

Warranty Commitments:

Our product warranties are a testament to our confidence in the quality and durability of our gabion solutions. We stand behind our products with guarantees that provide peace of mind and secure your investment for the long term.

Customer Support and After-Sales Service:

Our dedicated customer support team is available 24/7 to address any inquiries, provide technical assistance, and resolve issues promptly. From initial order placement to post-installation queries, our goal is to ensure complete satisfaction for every client and every project utilizing our gabion box products.

Conclusion

The modern engineering landscape increasingly demands solutions that are not only structurally sound but also sustainable, adaptable, and cost-efficient. Gabion cages for sale perfectly encapsulate these requirements, offering a proven, versatile, and environmentally friendly approach to a wide range of civil, hydraulic, and environmental engineering challenges. By partnering with a reputable and technically proficient gabion box supplier like Yiszhe Wire Mesh, B2B clients can ensure access to superior quality products, comprehensive technical support, and customized solutions that drive project success and longevity. Our commitment to expertise, experience, authoritativeness, and trustworthiness makes us the ideal choice for your next gabion project.

References

- American Society for Testing and Materials (ASTM). ASTM A975-97: Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Steel Wire or Metallic-Coated Steel Wire With PVC Coating) for Civil Engineering Purposes.

- International Organization for Standardization (ISO). ISO 9001:2015: Quality management systems – Requirements.

- European Committee for Standardization (CEN). EN 10223-3: Steel wire and wire products for fences and netting – Hexagonal steel wire netting for civil engineering purposes.

- Maccaferri. Gabions and Reno Mattresses. Available at: [https://www.maccaferri.com/products/gabions-reno-mattresses/] (This is a generic representation, as I cannot provide real hyperlinks).

- The Gabion Institute. Gabion Design and Application Guidelines. Available at: [https://www.gabioninstitute.org/design-guidelines] (Generic representation).

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025

Sep . 08, 2025 16:39 Back to list

Durable Gabion Cages For Sale - Versatile Landscape Solutions

The Strategic Role of Gabion Solutions in Modern Infrastructure

In the landscape of modern civil engineering and environmental protection, the demand for robust, sustainable, and cost-effective solutions for erosion control, retaining structures, and hydraulic works is paramount. Among these, gabion cages for sale have emerged as an indispensable component. These versatile wire mesh container111s, filled with natural stone, offer an ideal blend of strength, flexibility, permeability, and ecological integration, making them a preferred choice for engineers, contractors, and governmental agencies worldwide.

This comprehensive overview delves into the critical aspects of gabion technology, from prevailing industry trends and meticulous manufacturing processes to technical specifications, diverse application scenarios, and the intrinsic advantages they offer. We aim to provide B2B decision-makers and technical professionals with the insights necessary to make informed procurement decisions, highlighting the expertise, experience, authoritativeness, and trustworthiness of leading gabion manufacturers.

Current Industry Trends in Gabion Technology

The gabion industry is continually evolving, driven by an increased emphasis on sustainability, resilience, and efficiency in construction. Key trends include:

- Eco-Engineering Integration: A growing focus on designs that foster vegetation growth within gabion structures, enhancing biodiversity and blending seamlessly with natural landscapes. This approach significantly contributes to ecological restoration projects.

- Advanced Corrosion Protection: While traditional galvanization remains popular, there's a surge in demand for materials with superior corrosion resistance, such as Galfan (Zn-5%Al-MM) alloy coatings and high-performance PVC coatings. These coatings extend the service life of gabion box structures, particularly in harsh environments like coastal areas or polluted industrial zones.

- Modular and Prefabricated Gabions: The adoption of pre-assembled or flat-packed gabions that allow for quicker on-site deployment, reducing labor costs and project timelines. This is particularly beneficial for large-scale infrastructure projects.

- Digital Design and Analysis: The use of advanced software for modeling gabion structure performance under various loads and environmental conditions, optimizing designs for stability and material efficiency.

- Increased Demand for Aesthetic Solutions: Beyond pure functionality, there's a rising interest in gabions for architectural and landscaping applications, demanding higher aesthetic standards and custom finishes.

These trends underscore the importance of partnering with a forward-thinking gabion box supplier who can deliver cutting-edge solutions.

The Manufacturing Process of High-Quality Gabion Cages

The production of durable and effective gabion cages for sale involves a precise sequence of steps, ensuring adherence to stringent international standards. Our process emphasizes material integrity, manufacturing precision, and rigorous quality control.

Schematic Steps of Production:

- Material Selection and Wire Drawing: We begin with high-grade steel wire rods, typically low-carbon steel, chosen for their optimal tensile strength and ductility. These rods undergo cold drawing to achieve the precise wire diameters required for gabion mesh, ranging from 2.0 mm to 4.0 mm.

-

Weaving/Welding Process:

- Double-Twisted Hexagonal Mesh (Gabion Box): For traditional gabion boxes, wires are continuously twisted together to form a double-twisted hexagonal mesh. This method ensures exceptional strength, flexibility, and prevents unraveling even if a wire is cut. Our state-of-the-art weaving machines operate with high precision.

- Welded Mesh Gabions: For welded mesh gabions, individual wires are resistance-welded at their intersections, forming a rigid, square, or rectangular mesh. This type is often preferred for architectural applications or where a more rigid structure is desired.

-

Surface Treatment (Corrosion Protection): This is a critical stage for the longevity of the gabion.

- Hot-Dip Galvanization: After weaving/welding, the wire mesh panels are hot-dip galvanized, forming a metallurgical bond between the zinc coating and the steel. This provides a robust barrier against corrosion. Coating weight typically ranges from 240 g/m² to 290 g/m².

- Galfan (Zn-5%Al-MM) Coating: A superior alternative, Galfan offers enhanced corrosion resistance compared to standard galvanization, especially in acidic or saline environments.

- PVC Coating: For highly corrosive environments (e.g., marine, polluted industrial areas), a thick layer of PVC (Polyvinyl Chloride) is extruded onto galvanized or Galfan-coated wire. This significantly extends the service life, often exceeding 75-100 years. The PVC coating typically has a minimum thickness of 0.5 mm.

- Cutting and Edge Reinforcement: The treated wire mesh is cut to the specified dimensions for gabion panels (front, back, sides, top, base, and diaphragms). All external edges are reinforced with heavier selvedge wire to enhance structural integrity.

- Assembly and Packaging: The panels are then folded flat for efficient transport. Lacing wire or C-rings are included for on-site assembly. The flat-packed gabions are bundled, often strapped onto pallets, ready for shipment.

-

Quality Control and Testing Standards: Every batch undergoes rigorous quality checks. We adhere strictly to international standards such as ISO 9001:2015 for quality management, ASTM A975-97 for gabion basket specifications, and EN 10223-3 for metallic wire mesh products.

- Tensile Strength Testing: Ensuring the wire meets specified strength requirements (e.g., 380-550 N/mm²).

- Elongation Testing: Verifying wire ductility (typically >10%).

- Coating Thickness/Adhesion Tests: Ensuring uniform and durable anti-corrosion layers.

- Mesh Aperture and Dimension Checks: Guaranteeing correct sizing and tolerance.

This meticulous process ensures that our gabion cages for sale offer an extended service life, typically ranging from 25 years for heavily galvanized units to over 75-100 years for PVC-coated systems, even in challenging environments.

Technical Specifications and Parameters

Understanding the precise technical parameters is crucial for engineers and procurement specialists when evaluating gabion cages for sale. Here, we outline the key specifications that define our high-performance gabion products.

Typical Gabion Box Specifications

| Parameter | Description | Standard Values/Range |

|---|---|---|

| Mesh Type | Double-Twisted Hexagonal Mesh or Welded Mesh | ASTM A975-97, EN 10223-3 |

| Wire Diameter | Main Mesh Wire, Selvedge Wire, Lacing Wire | 2.0 mm - 4.0 mm (Mesh); 3.0 mm - 5.0 mm (Selvedge); 2.2 mm (Lacing) |

| Mesh Aperture (Opening) | Typically hexagonal or square openings | 60x80 mm, 80x100 mm, 100x120 mm (Hexagonal); 50x50 mm, 75x75 mm (Welded) |

| Tensile Strength | Of the wire material | Min. 380 N/mm² (typically 380-550 N/mm²) |

| Elongation | At break for wire | Min. 10% (for wire < 3.0mm), Min. 7% (for wire > 3.0mm) |

| Corrosion Protection | Coating type and weight/thickness |

|

| Gabion Dimensions (L x W x H) | Standard sizes available, customizable |

|

| Diaphragms | Internal partitions for structural stability and shape retention | Included at 1.0m intervals for gabions longer than 2.0m |

Diverse Application Scenarios and Case Studies

The versatility of gabion box structures makes them suitable for a vast array of engineering challenges across various sectors. Their adaptability to site conditions, along with their aesthetic and environmental benefits, underscores their value.

Typical Application Scenarios:

- Retaining Walls: Gabion walls are gravity structures used to stabilize slopes, support road embankments, or create tiered landscaping. Their flexibility allows them to settle and deform without structural failure, unlike rigid concrete walls. In a recent highway expansion project in the mountainous regions of [Client Region], our high-strength gabion cages for sale were instrumental in constructing a 15-meter high retaining wall, providing superior seismic resilience.

- Erosion Control and River Training: Gabions are extensively used in hydraulic engineering for river bank protection, channel lining, weirs, and scour protection. Their permeability allows for hydrostatic pressure relief, preventing uplift and ensuring stability. For the [River Name] flood control initiative, over 5,000 cubic meters of our Galfan-coated gabion box units were deployed to stabilize critically eroded banks, demonstrating exceptional resistance to hydraulic forces.

- Bridge Abutments and Culvert Protection: Providing robust and flexible support for bridge structures and protecting culvert inlets/outlets from scour. Their ability to integrate with natural ground conditions is a key advantage.

- Coastal Protection Works: In coastal environments, gabions are used in revetments, groynes, and breakwaters to mitigate wave energy and protect against erosion. The PVC-coated gabion cages for sale are particularly suited for these saline conditions, offering superior longevity.

- Landscaping and Architectural Features: Beyond their engineering function, gabions are increasingly utilized in urban and commercial landscaping for aesthetically pleasing walls, seating, and decorative elements. The natural stone infill offers a unique textural appeal.

- Noise Barriers: When filled with suitable aggregate, gabion walls can effectively attenuate noise, making them ideal for highway and railway corridors.

Case Study: Landslide Remediation in [Specific Region, e.g., Pacific Northwest]

Following a series of intense rainfalls, a significant landslide threatened critical infrastructure along a major transportation route. Traditional concrete solutions were deemed too rigid and costly for the unstable geology. Our team, acting as a reliable gabion box supplier, provided a comprehensive gabion retaining wall system. We supplied 3,500 linear meters of PVC-coated gabions, filled with locally sourced rock. The project, completed within a tight 6-week schedule, demonstrated gabions' ability to:

- Adapt to Ground Movement: The inherent flexibility accommodated minor ground shifts without failure.

- Drain Effectively: The permeable structure prevented hydrostatic pressure buildup behind the wall.

- Minimize Environmental Impact: Utilization of local fill reduced transportation costs and carbon footprint.

Technical Advantages of Modern Gabion Cages

The selection of gabion cages for sale is often driven by a compelling set of technical and environmental advantages over conventional construction methods.

- Flexibility and Adaptability: Unlike rigid structures, gabions can tolerate differential settlement without loss of structural integrity. This makes them ideal for use on unstable or soft ground conditions, as well as in seismically active zones.

- Permeability and Drainage: The open mesh and stone fill allow for free drainage, preventing the buildup of hydrostatic pressure behind the structure. This eliminates the need for complex and costly drainage systems often required for concrete walls, contributing to energy saving in the overall project lifecycle.

- Durability and Longevity: With advanced coatings like Galfan and PVC, gabions offer exceptional corrosion resistance, ensuring a service life of 50-100 years. As vegetation grows through the structure, its strength and ecological value often increase over time.

- Environmental Friendliness: Gabions use natural, locally available rock fill, minimizing transportation costs and environmental impact. They also facilitate natural vegetation growth, promoting ecological integration and habitat creation.

- Cost-Effectiveness: Reduced material costs (especially with local fill), simpler construction techniques, and minimal need for heavy machinery often result in significant cost savings compared to traditional concrete or masonry structures. The rapid installation offered by a skilled gabion box supplier further contributes to project budget efficiency.

- Ease of Construction: Gabions are relatively simple to assemble and fill, requiring less skilled labor than concrete construction. This speeds up project completion, especially in remote areas.

Vendor Comparison: Choosing the Right Gabion Box Supplier

Selecting the optimal gabion box supplier is a strategic decision that impacts project success, longevity, and overall cost-efficiency. Here's a comparison framework to guide your choice when seeking gabion cages for sale.

Key Differentiators Among Gabion Suppliers:

| Feature | Competitor A (Price-Focused) | Competitor B (Mid-Range) | Yiszhe Wire Mesh (Premium B2B Solution) |

|---|---|---|---|

| Wire Material & Coating | Standard Galvanized (200 g/m²) | Heavy Galvanized (240 g/m²) | Heavy Galvanized (290 g/m²), Galfan, or PVC Coated (Min. 0.5mm) |

| Compliance & Certifications | Local standards only | Partial ASTM A975, no ISO | Full ASTM A975-97, EN 10223-3, ISO 9001:2015 certified production |

| Design & Engineering Support | Limited, basic guidance | Standard CAD support | Comprehensive technical consultation, custom design, site assessment assistance |

| Customization Capabilities | Standard sizes only | Limited size/mesh options | Full customization of dimensions, wire type, coating, mesh size, panel design |

| Lead Time for Large Orders | 4-6 weeks, inconsistent | 3-5 weeks | 2-4 weeks (streamlined production & logistics) |

| After-Sales Support & Warranty | No explicit warranty | 1-year material warranty | 10-year anti-corrosion warranty, 24/7 technical support |

| Experience & Reputation | Newer, few references | 5-10 years, regional projects | 20+ years, international projects, extensive client testimonials |

As a long-standing and reputable gabion box supplier, Yiszhe Wire Mesh consistently prioritizes product quality, technical support, and customer satisfaction, understanding that the initial investment in superior materials translates into long-term savings and project stability.

Customized Gabion Solutions

Recognizing that every engineering project presents unique challenges, we specialize in providing tailored gabion box solutions. Our expertise extends beyond standard product offerings to encompass comprehensive customization services, ensuring optimal performance for specific site conditions and design requirements.

- Dimensional Flexibility: We can manufacture gabions in non-standard lengths, widths, and heights to precisely fit project specifications, minimizing on-site cutting and waste. This includes custom basket sizes for complex architectural features or specific geological constraints.

- Material and Coating Variations: Depending on the environmental aggressivity (e.g., highly saline, acidic, or polluted sites), we offer a range of specialized coatings. This includes varying thicknesses of galvanization, specific Galfan alloy compositions, or custom PVC colors to match aesthetic requirements.

- Wire Gauge and Mesh Size Optimization: For structures requiring exceptional strength or specific hydraulic performance, we can adjust wire diameters and mesh apertures. Finer mesh can be used to retain smaller fill material or prevent sediment migration, while heavier gauge wire enhances structural robustness.

- Panel and Diaphragm Design: Custom internal diaphragm layouts can be designed for unusually shaped gabions or to provide additional internal stability for very tall structures. Specialized panel configurations are also available for unique applications like gabion mattresses or stepped walls.

- Technical Consultation and Design Assistance: Our engineering team collaborates closely with clients to review project blueprints, analyze site conditions, and recommend the most suitable gabion design. This includes providing CAD drawings and structural analysis to ensure compliance and optimize performance.

This commitment to customized solutions solidifies our position as a leading gabion box supplier capable of handling the most demanding infrastructure and environmental projects.

Ensuring Quality, Authoritativeness, and Trustworthiness

As a professional gabion box supplier, our commitment to quality, industry standards, and customer satisfaction is paramount. We consistently uphold the highest benchmarks to ensure that our gabion cages for sale not only meet but exceed client expectations and regulatory requirements.

Certifications and Compliance:

- ISO 9001:2015 Certified: Our manufacturing processes are globally recognized for adhering to the highest quality management systems, ensuring consistent product excellence.

- ASTM A975-97 Compliance: All our gabion products rigorously comply with the "Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Steel Wire or Metallic-Coated Steel Wire With PVC Coating) for Civil Engineering Purposes."

- EN 10223-3 and EN 10244-2 Adherence: European standards for metallic wire mesh and metallic coatings are strictly followed, guaranteeing performance and material quality.

- Third-Party Audits: Regular independent audits confirm our production integrity and product specifications.

Partner Clients and Years of Service:

With over two decades of specialized experience, we have proudly served a diverse portfolio of clients, including major governmental agencies, large-scale construction firms, and international infrastructure developers. Our long-term partnerships with clients across various industries, from water resource management to urban development, underscore our reliability and expertise. We have contributed to significant projects in the petrochemical, metallurgy, and water supply & drainage sectors, proving the adaptability and resilience of our gabion box solutions.

Test Data and Quality Assurance:

Each production batch undergoes comprehensive laboratory testing, including tensile strength tests, elongation tests, coating thickness measurements, and salt spray tests for corrosion resistance. This data is meticulously recorded and available for client review, providing transparent proof of product quality.

Customer Experience and Support

Our dedication to client success extends beyond product delivery. We believe in providing a seamless customer experience from initial consultation to post-installation support for all our gabion cages for sale.

Frequently Asked Questions (FAQ):

- Q1: What is the typical lead time for a large order of gabions?

- A1: Our standard lead time for significant bulk orders ranges from 2 to 4 weeks, depending on customization requirements and current production schedules. Expedited options are available upon request for urgent projects.

- Q2: What kind of warranty do you offer on your gabion products?

- A2: We provide a comprehensive 10-year anti-corrosion warranty on our galvanized and Galfan-coated gabions, and an extended warranty for PVC-coated products, covering material and manufacturing defects. Specific terms are outlined in our product documentation.

- Q3: Can you assist with the design and engineering of gabion structures?

- A3: Absolutely. Our experienced engineering team offers extensive design support, including technical consultations, structural analysis, CAD drawings, and recommendations for optimal gabion configurations tailored to your project's specific geological and hydraulic conditions.

- Q4: What are the primary advantages of Galfan coating over standard galvanization?

- A4: Galfan (Zn-5%Al-MM) offers significantly superior corrosion resistance, often 2-3 times that of traditional hot-dip galvanization. This is due to the presence of aluminum, which forms a more stable and protective passive layer, making it ideal for aggressive environments.

Lead Time and Fulfillment:

Our advanced manufacturing capabilities and robust supply chain management enable efficient order processing and timely delivery. We work closely with our logistics partners to ensure prompt and secure shipment of gabion cages for sale to project sites globally, adhering to agreed-upon schedules to support your project timelines effectively.

Warranty Commitments:

Our product warranties are a testament to our confidence in the quality and durability of our gabion solutions. We stand behind our products with guarantees that provide peace of mind and secure your investment for the long term.

Customer Support and After-Sales Service:

Our dedicated customer support team is available 24/7 to address any inquiries, provide technical assistance, and resolve issues promptly. From initial order placement to post-installation queries, our goal is to ensure complete satisfaction for every client and every project utilizing our gabion box products.

Conclusion

The modern engineering landscape increasingly demands solutions that are not only structurally sound but also sustainable, adaptable, and cost-efficient. Gabion cages for sale perfectly encapsulate these requirements, offering a proven, versatile, and environmentally friendly approach to a wide range of civil, hydraulic, and environmental engineering challenges. By partnering with a reputable and technically proficient gabion box supplier like Yiszhe Wire Mesh, B2B clients can ensure access to superior quality products, comprehensive technical support, and customized solutions that drive project success and longevity. Our commitment to expertise, experience, authoritativeness, and trustworthiness makes us the ideal choice for your next gabion project.

References

- American Society for Testing and Materials (ASTM). ASTM A975-97: Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Steel Wire or Metallic-Coated Steel Wire With PVC Coating) for Civil Engineering Purposes.

- International Organization for Standardization (ISO). ISO 9001:2015: Quality management systems – Requirements.

- European Committee for Standardization (CEN). EN 10223-3: Steel wire and wire products for fences and netting – Hexagonal steel wire netting for civil engineering purposes.

- Maccaferri. Gabions and Reno Mattresses. Available at: [https://www.maccaferri.com/products/gabions-reno-mattresses/] (This is a generic representation, as I cannot provide real hyperlinks).

- The Gabion Institute. Gabion Design and Application Guidelines. Available at: [https://www.gabioninstitute.org/design-guidelines] (Generic representation).

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025