Jul . 26, 2024 05:39 Back to list

Durable and Versatile Welded Wire Mesh Panels for Various Construction and Industrial Applications

The Versatility and Benefits of Welded Mesh Panels

Welded mesh panels have gained significant popularity in a variety of industries and applications, thanks to their durability, strength, and versatility. Crafted from high-quality steel wire, welded mesh is formed by welding intersecting wires at their joint points, creating a grid-like structure. This robust design caters to numerous uses, including construction, agriculture, industrial applications, and even artistic designs.

One of the primary advantages of welded mesh panels is their structural integrity. The welding process creates a uniform distribution of strength throughout the mesh, making it highly resistant to bending and deformation. Unlike other forms of fencing or panels that may sag over time, welded mesh retains its shape and effectiveness, providing long-lasting solutions for fencing, reinforcement, and even shelving. Whether used in road safety barriers, animal enclosures, or as reinforcement in concrete slabs, welded mesh panels deliver reliability in various conditions.

In construction, welded mesh panels are commonly employed to reinforce concrete structures, ensuring that they can withstand stress and strain. The use of welded mesh in concrete equations minimizes the risk of cracks and other structural failures, enhancing the longevity and stability of buildings, bridges, and other infrastructures. Architects and engineers appreciate the predictability and strength that welded mesh adds to their designs, enabling them to create safer environments for occupants.

In the agricultural sector, welded mesh panels serve multiple purposes, from fencing to livestock containment. Farmers often use these panels to create secure enclosures for animals, preventing escapes while ensuring adequate airflow and visibility. The durable nature of welded mesh also resists corrosion and rust, making it ideal for outdoor use where it can be exposed to various weather conditions. Moreover, welded mesh is versatile; it can be cut and shaped to fit specific requirements, providing tailored solutions for different farming needs.

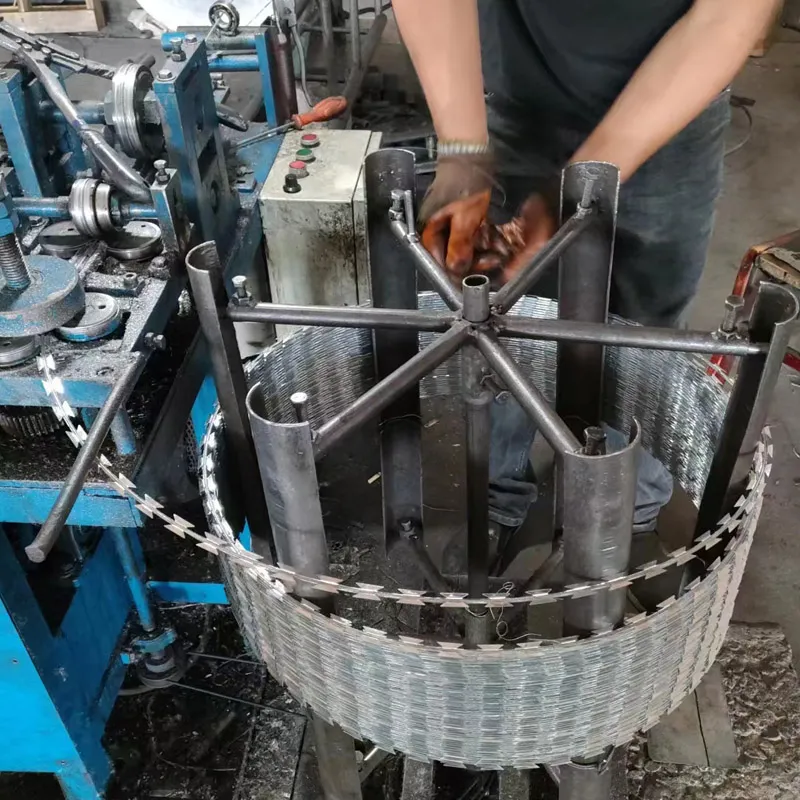

welded mesh panels

In industrial environments, welded mesh panels find application as safety barriers, storage solutions, and in the protection of machinery. Their strength ensures that they can prevent unauthorized access to hazardous areas, thereby enhancing workplace safety. Additionally, these panels can be fashioned into shelving units that allow for maximum visibility and organization in warehouses, thereby improving efficiency.

Beyond their practical applications, welded mesh panels have also found their way into the world of art and design. Artists and designers utilize welded mesh in sculptures and installations, taking advantage of its unique aesthetic qualities. The combination of transparency and structure allows for the exploration of light and form, inviting viewers to engage with the artwork in thoughtful ways.

The installation of welded mesh panels is generally straightforward, making them a cost-effective option for many applications. They can be prefabricated off-site, which streamlines the construction process and reduces labor costs. Additionally, the panels can be treated with various coatings to enhance their longevity, providing options for aesthetically pleasing finishes that complement different projects.

In conclusion, welded mesh panels represent an innovative solution that combines functionality with aesthetic appeal. Their applications span across industries, from construction and agriculture to safety and art. The inherent strength, durability, and versatility of welded mesh panels ensure that they will continue to play a vital role in securing and enhancing spaces for years to come. Whether for practical use or artistic expression, welded mesh remains a favored choice for those seeking reliability and innovation in their projects.

-

Weather Resistance Properties of Quality Roofing Nails

NewsAug.01,2025

-

How Galvanised Iron Mesh Resists Corrosion in Harsh Environments

NewsAug.01,2025

-

Creative Landscaping Uses for PVC Coated Wire Mesh Panels

NewsAug.01,2025

-

Common Wire Nail Dimensions and Their Specific Applications

NewsAug.01,2025

-

Choosing the Right Welded Wire Sheets for Agricultural Fencing

NewsAug.01,2025

-

Anti - Climbing Features of Razor Wire Barriers

NewsAug.01,2025