Sep . 19, 2025 10:30 Back to list

Diamond Razor Wire: High Security Fencing & Perimeter Protection

The Evolution of High-Security Perimeters: Understanding Diamond Razor Wire

In an increasingly complex security landscape, the demand for robust and impenetrable perimeter solutions has never been higher. For critical infrastructure, correctional facilities, and high-value industrial sites, conventional fencing often falls short. This is where advanced solutions like diamond razor wire emerge as a definitive deterrent. Representing the pinnacle of physical security barriers, this specialized form of razor wire provides unparalleled protection against unauthorized entry, blending aggressive deterrence with engineered durability.

Our focus herein is to provide B2B decision-makers and technical personnel with an in-depth understanding of its manufacturing, technical specifications, diverse applications, and inherent advantages, distinguishing it from standard security barriers.

Industry Trends in Advanced Perimeter Security

The global perimeter security market is undergoing significant transformation, driven by geopolitical instability, evolving threat vectors, and the increasing value of protected assets. Key trends include the integration of physical barriers with electronic surveillance, the demand for longer-lasting and more resilient materials, and the optimization of installation and maintenance costs. Diamond razor wire stands at the forefront of these developments, offering a robust, low-maintenance physical deterrent that complements advanced security systems. Leading razor wire suppliers are constantly innovating to meet stringent international standards and project-specific demands, ensuring that facilities remain secure against increasingly sophisticated intrusion attempts.

The market is witnessing a shift towards higher-grade materials, such as hot-dipped galvanized and stainless steel, to extend service life in corrosive environments. Furthermore, ease of deployment without compromising security integrity is a critical factor for many end-users.

Technical Specifications of Diamond Razor Wire

The "diamond" configuration refers to the distinctive blade pattern and often the tight, helical coiling that enhances its deterrent effect and structural rigidity. This design principle maximizes the number of sharp edges presented to an intruder while minimizing the potential for easy manipulation or cutting. The material science and precise engineering behind diamond razor wire are critical to its efficacy.

Key Structural Components:

- Core Wire: Typically high-tensile steel wire (e.g., 2.5mm or 2.6mm diameter), hot-dipped galvanized or stainless steel (SS304, SS316). This provides the structural integrity and prevents easy cutting or bending. Its tensile strength often exceeds 1500 MPa.

- Razor Blades: Stamped from galvanized steel sheets (e.g., 0.5mm thickness) or stainless steel. The diamond pattern is precisely cut to create multiple sharp, piercing points that are extremely difficult to bypass.

- Coiling: Available in single coil, crossed coil (concertina), or flat wrap configurations, each optimized for specific threat levels and aesthetic considerations. The tight helical coiling significantly increases the barrier's density.

Typical Product Specifications:

| Parameter | Specification Range | Technical Detail |

|---|---|---|

| Material | Hot-dipped Galvanized Steel (HDG), Stainless Steel (SS304, SS316) | Galvanization typically 60-275 g/m², SS for extreme corrosion resistance. |

| Blade Thickness | 0.5 mm - 0.6 mm | Critical for preventing easy bending or cutting. |

| Core Wire Diameter | 2.5 mm - 2.8 mm | High-tensile steel, often >1500 MPa for robust resistance. |

| Coil Diameter (Concertina) | 450 mm, 600 mm, 750 mm, 900 mm, 1000 mm | Larger diameters offer greater deterrent and physical depth. |

| Blade Length | 12 mm - 65 mm (dependent on RBT type) | Optimized for maximum deterrent and entanglement. |

| Barb Spacing | 15 mm - 100 mm (dependent on RBT type) | Ensures continuous, dense coverage of sharp points. |

| Service Life (HDG) | 10-25 years | Dependent on galvanization thickness and environmental conditions. |

| Service Life (SS) | 25+ years | Superior resistance to corrosion, especially in coastal or industrial zones. |

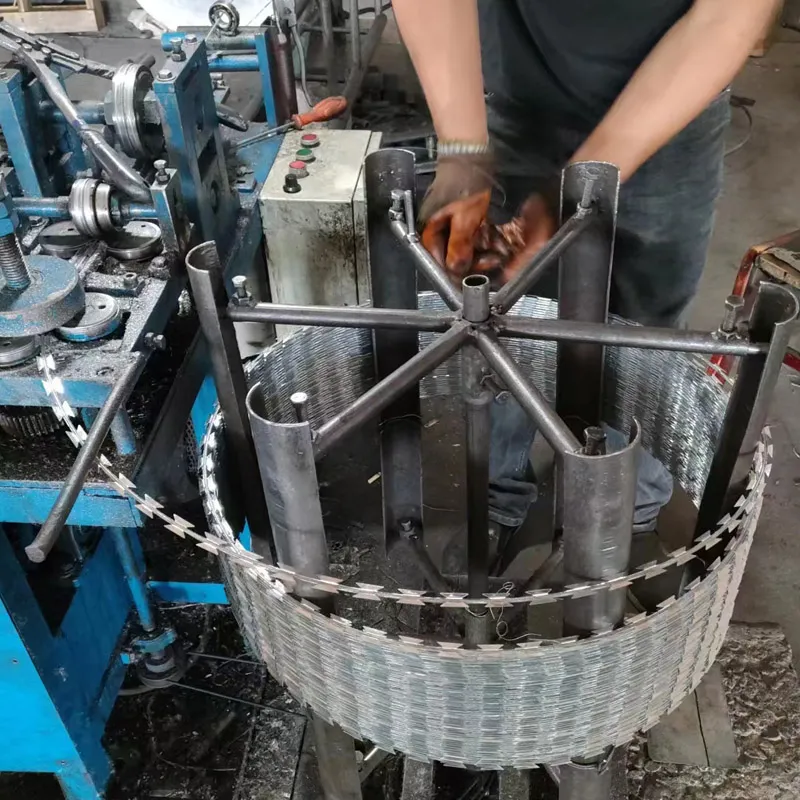

The Manufacturing Process: Precision Engineering for Ultimate Security

The production of diamond razor wire is a meticulously controlled process designed to ensure consistent quality, formidable strength, and long-term performance. It adheres to international standards such as ISO 9001 for quality management and relevant ASTM/ANSI material specifications.

Process Flow:

- Material Selection & Preparation: High-grade steel coils (carbon steel or stainless steel) are sourced. For galvanized razor wire, the steel undergoes hot-dipped galvanization, ensuring a thick, uniform zinc coating that meets or exceeds ASTM A653/A653M standards for corrosion resistance. Stainless steel (SS304/SS316) is used for superior resistance in harsh environments.

- Core Wire Production: High-tensile strength wire is drawn to precise diameters (e.g., 2.5mm or 2.6mm). This wire is often pre-galvanized or made from stainless steel to form the structural backbone.

- Blade Stamping (Precision Punching): Flat steel strips are fed into high-precision stamping machines. These machines utilize specialized tooling (dies) to cut the characteristic diamond-shaped blades. The accuracy of this process is paramount, ensuring uniform blade dimensions, sharpness, and barb spacing. This is akin to highly specialized CNC machining for metal sheets, guaranteeing consistent aggressive profiles.

- Assembly (Crimping/Rolling): The stamped razor blades are then mechanically crimped onto the core wire using dedicated machinery. This creates a secure, integral bond, preventing blades from detaching or rotating. The core wire acts as a spine, distributing tension and maintaining structural integrity.

- Coiling & Forming: The assembled razor wire is then coiled into its final configuration – typically a helical (concertina) coil. Clip wires are strategically placed and secured to interconnect adjacent loops, forming a robust, entangled barrier that significantly increases deterrence and prevents separation.

- Quality Control & Testing: Throughout the process, rigorous quality checks are performed. This includes:

- Material Verification: Ensuring steel grade, zinc coating thickness (for HDG), and chemical composition (for SS) meet specifications.

- Dimensional Accuracy: Checking blade length, barb spacing, core wire diameter, and coil diameter.

- Adhesion & Strength: Testing the crimp strength of blades to the core wire and the tensile strength of the overall assembly.

- Corrosion Resistance Tests: Salt spray tests (ASTM B117) are conducted on samples to predict real-world service life.

- Packaging & Dispatch: Finished coils are compressed and securely packaged for efficient transport and deployment, often meeting international shipping standards.

This engineered approach ensures that the finished diamond razor wire product delivers superior performance, especially in terms of its targeted advantages like exceptional corrosion resistance and extended service life. For example, the precise control over galvanization thickness directly correlates to a service life of 15-25 years in moderate climates, drastically reducing replacement costs and maintenance for target industries such as petrochemical, metallurgy, and water supply & drainage facilities which often face corrosive elements.

Application Scenarios and Target Industries

The robust security profile of diamond razor wire makes it indispensable across a spectrum of high-stakes environments where perimeter integrity is paramount. Its passive yet aggressive deterrent capability is a crucial component of multi-layered security strategies.

- Military & Defense Installations: Providing an impenetrable barrier around bases, armories, and training grounds.

- Correctional Facilities: Enhancing the security of prison walls and internal enclosures to prevent escapes and unauthorized access.

- Critical Infrastructure: Protecting power plants, substations, water treatment facilities, gas pipelines, and communication hubs from sabotage or theft. The corrosion resistance of high-grade materials makes it ideal for these long-term, exposed applications.

- Petrochemical & Industrial Complexes: Securing refineries, chemical plants, and manufacturing facilities where valuable assets and hazardous materials require stringent protection. The resilience to industrial atmospheres is key here.

- Border Security: Forming formidable lines of defense along national borders to control illegal crossings.

- Data Centers & Server Farms: Guarding sensitive information infrastructure against physical breaches.

- High-Security Warehouses & Logistics Hubs: Protecting high-value goods and preventing cargo theft.

In these scenarios, the primary advantage of diamond razor wire is its capacity to act as a significant physical and psychological deterrent, reducing the likelihood of intrusion and buying critical time for security personnel to respond. Its low maintenance and extended service life translate directly into long-term cost savings (energy saving in terms of active security resources) for these high-security installations.

Technical Advantages Over Traditional Barriers

When evaluating perimeter security solutions, the distinct advantages of diamond razor wire become apparent, especially when compared to older technologies such as standard razor wire and barbed wire.

Superior Deterrence & Physical Barrier:

The aggressive diamond-shaped blades and tightly coiled configuration present a much more formidable physical obstacle. Unlike simple barbed wire, which can often be cut with basic tools or traversed with relative ease, diamond razor wire causes entanglement and significant injury, making any attempt to breach highly perilous and time-consuming. This acts as a powerful psychological deterrent.

Enhanced Durability and Longevity:

Manufactured from high-tensile, galvanized, or stainless steel, diamond razor wire is engineered for extreme weather resistance and prolonged service life. This material integrity ensures the barrier remains effective for decades, even in harsh climates, significantly reducing the need for frequent replacement or maintenance compared to less robust alternatives. The specific quality of galvanization or use of stainless steel directly translates to superior corrosion resistance.

Cost-Effectiveness Over Lifetime:

While the initial investment for diamond razor wire might be slightly higher than traditional barbed wire, its extended service life, minimal maintenance requirements, and superior security performance result in a much lower total cost of ownership (TCO) over the operational lifespan. It's a strategic investment in long-term security infrastructure.

Comparison: Diamond Razor Wire vs. Barbed Wire

| Feature | Diamond Razor Wire | Barbed Wire |

|---|---|---|

| Security Level | High to Extreme: Aggressive blades, difficult to cut/traverse without significant injury. | Low to Medium: Minimal deterrent, relatively easy to cut or bypass with basic tools. |

| Deterrent Factor | Very High: Strong visual and physical deterrent, high psychological impact. | Moderate: Limited visual and physical deterrent. |

| Material Strength | High-tensile steel core wire, robust stamped blades. | Lower tensile wire, simple twisted barbs. |

| Corrosion Resistance | Excellent (HDG >200g/m² or SS304/SS316) | Good (Standard galvanization 30-80g/m²) |

| Service Life | 10-25+ years (HDG), 25+ years (SS) | 5-15 years (depending on galvanization) |

| Installation Complexity | Requires specialized safety equipment and trained personnel. | Relatively simple, but still requires care. |

| Maintenance | Very low due to durability and corrosion resistance. | Low, but susceptible to earlier degradation and sagging. |

| Cost-Effectiveness (Long-term) | High: Lower TCO due to longevity and security. | Moderate: Higher TCO due to shorter lifespan and lower security. |

Choosing the Right Partner: Vendor Comparison and Customized Solutions

Selecting the appropriate razor wire suppliers is as crucial as choosing the right product. A reliable vendor offers not just quality products but also comprehensive support and the flexibility for tailored solutions.

Key Factors for Vendor Comparison:

- Certifications and Compliance: Ensure the supplier adheres to international quality management systems (e.g., ISO 9001) and product standards (e.g., ASTM, ANSI, BS EN). Our products are manufactured under strict ISO quality protocols.

- Material Traceability: A reputable supplier provides full traceability of raw materials, verifying the quality and origin of steel and coatings.

- Experience and Reputation: Look for vendors with a proven track record, extensive years of service (e.g., over 20 years in specialized wire mesh products), and a portfolio of successful projects with reputable partner clients in demanding sectors.

- Technical Support & Expertise: The ability to provide expert guidance on product selection, installation, and maintenance is invaluable.

- Customization Capabilities: For specific site requirements, customized solutions are often necessary.

Customized Solutions:

A one-size-fits-all approach rarely suffices for high-security applications. We specialize in providing tailored diamond razor wire solutions, including:

- Varied Coil Diameters: From 450mm to 1000mm, to match specific fence heights and threat levels.

- Blade Types: Different Razor Barbed Tape (RBT) types (e.g., BTO-22, CBT-65) with varying blade lengths and barb spacing for different levels of aggression and entanglement.

- Material & Coating Options: Choice between heavy galvanized, zinc-aluminum alloy coated, or various grades of stainless steel (SS304, SS316) to ensure optimal performance in diverse environmental conditions.

- Flat Wrap & Welded Mesh Integration: Solutions for combining razor wire with existing structures or integrating it into welded mesh panels for enhanced security.

Real-World Application Case Studies

The effectiveness of diamond razor wire is best illustrated through its successful deployment in various demanding environments.

Case Study 1: Border Patrol Enhancement Project (Southwest Region)

- Challenge: An international border segment experienced persistent breaches due to conventional fencing being easily cut or scaled. The harsh desert environment demanded materials with extreme corrosion resistance and UV stability.

- Solution: Over 50 kilometers of 900mm diameter diamond razor wire, made from high-tensile SS316 stainless steel, was installed atop existing perimeter fences. The deployment was completed in Q3 2022.

- Outcome: Within six months of installation, unauthorized crossings in the protected segments dropped by 85%. The stainless steel construction showed no signs of degradation despite intense sun exposure and sand erosion, validating its superior service life and corrosion resistance.

Case Study 2: High-Security Data Center (Urban Core)

- Challenge: A new data center required an uncompromising perimeter security solution to protect critical digital infrastructure, needing to integrate seamlessly with electronic detection systems and offer a clean aesthetic while maintaining high security.

- Solution: Flat wrap diamond razor wire (750mm height, HDG with PVC coating for visual integration) was discretely installed on top of the pre-existing concrete perimeter wall.

- Outcome: The solution provided a robust physical barrier that was less visually intrusive than concertina coils but equally effective. The incident log recorded zero physical breaches since its installation in Q1 2023, and the low-profile design satisfied urban planning requirements.

Ensuring Trust and Reliability

Frequently Asked Questions (FAQ)

Q: What is the primary difference between diamond razor wire and conventional razor wire?

A: Diamond razor wire typically refers to a specific, often more aggressive blade pattern and a tighter, more robust coiling (like CBT-65 or BTO-30 patterns) which maximizes deterrence and entanglement points. It generally utilizes higher-grade materials and stricter manufacturing tolerances for enhanced durability and security compared to more basic razor wire types like BTO-10.

Q: How does its service life compare to standard barbed wire?

A: Diamond razor wire, especially in hot-dipped galvanized or stainless steel variants, offers a significantly longer service life (10-25+ years for HDG, 25+ years for SS) compared to standard barbed wire (5-15 years). This is due to superior material quality and corrosion protection.

Q: Is specialized installation required?

A: Yes, due to its aggressive nature, diamond razor wire requires professional installation by trained personnel using appropriate personal protective equipment (PPE). Our team can provide guidance and recommend experienced installers.

Lead Time and Fulfillment

Our advanced manufacturing capabilities ensure efficient production and timely delivery. Standard orders for common specifications of diamond razor wire typically have a lead time of 2-4 weeks. For large-scale projects or custom specifications, lead times will be confirmed upon order finalization, factoring in material sourcing and production complexity. We maintain robust logistics networks to ensure global distribution.

Warranty Commitments

We stand by the quality and durability of our products. Our diamond razor wire comes with a comprehensive warranty against manufacturing defects and premature corrosion (subject to material type and installation guidelines). Typical warranties range from 5 to 10 years, reflecting our confidence in the product's longevity and performance under specified conditions.

Customer Support and After-Sales Service

Our commitment extends beyond product delivery. We offer dedicated customer support, including technical assistance, product usage guidance, and troubleshooting. Our experienced team is available to assist with any queries, ensuring that your investment in diamond razor wire provides lasting peace of mind and security.

Conclusion

The strategic deployment of diamond razor wire is a critical decision for organizations seeking to establish formidable and lasting perimeter security. Its superior design, advanced materials, and meticulous manufacturing process translate into unparalleled deterrence, longevity, and overall cost-effectiveness. As a cornerstone of modern physical security, it offers the peace of mind that comes from knowing your assets and personnel are protected by a world-class barrier solution.

References

- ISO 9001:2015 Quality Management Systems. International Organization for Standardization.

- ASTM A653/A653M-20, Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process. ASTM International.

- ASTM B117-19, Standard Practice for Operating Salt Spray (Fog) Apparatus. ASTM International.

- Global Perimeter Security Market Report (Various editions, e.g., MarketsandMarkets, Allied Market Research).

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025