Oct . 11, 2025 11:35 Back to list

Diamond Razor Wire: High-Security, Durable, Anti-Corrosion

Field Notes on Diamond Razor Wire: What Pros Actually Buy, Test, and Install

If you spend enough time around perimeter contractors (I do), you learn there’s the catalog version of security hardware—and the real-world version. The latter is where diamond razor wire quietly dominates high-risk perimeters, especially when anti-climb and long service life matter. And yes, it’s a bit niche; not every wholesaler stocks true welded “diamond” razor mesh. But the sites that need it? They insist.

What’s trending now

Three shifts stand out: welded razor mesh in a diamond aperture (better rigidity), thicker coatings (Zn or Zn-Al) for coastal installs, and stricter documentation—salt-spray data and traceable coil IDs. Many customers say they’re done with “mystery zinc.” I get it; downtime costs more than a few dollars saved on tape.

Specification snapshot (typical, real-world may vary)

| Parameter | Common Options | Notes |

|---|---|---|

| Blade profile | BTO-10/12/22/30; CBT-60/65 | Blade ≈0.5±0.05 mm; aggressive profiles for anti-climb |

| Core wire | 2.5±0.1 mm high-tensile | ASTM A641/A or EN 10244-2 coated |

| Aperture (diamond) | 75×150 mm; 100×200 mm | Welded razor mesh sheets/panels |

| Coating | HDG ≥70 µm; Zn-Al; 304/316 SS | ISO 9227 salt spray references, site-dependent |

| Tensile strength | 600–1200 MPa | Higher TS = better cut resistance |

| Service life | ≈10–25 years | Climate, pollution, and maintenance drive outcome |

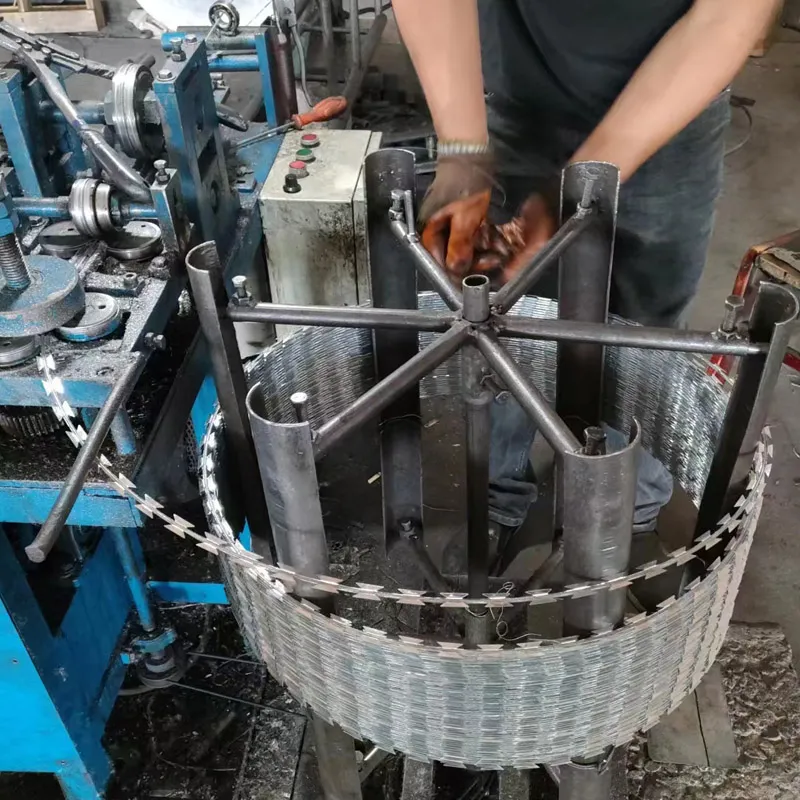

How it’s made (the short, honest version)

Materials: galvanized carbon steel strip for blades (ASTM A653/A), high-tensile galvanized core wire (ASTM A641/A), or full stainless for coastal zones. Methods: slit-and-stamp blades, crimp onto core, then weld intersections into a rigid diamond mesh—or run as concertina coils if the spec calls for it. Testing: coating mass per EN 10244-2, blade hardness checks, weld shear, and periodic ISO 9227 salt-spray exposure. I like seeing batch-level reports; many buyers ask for them now.

Where pros deploy it

- Airports, substations, data centers, and solar farms

- Oil & gas yards, logistics hubs, and seaports

- Perimeter upgrades on walls, chain-link toppers, and gates

Advantages people actually cite: rigid sheet geometry (fewer sagging points), nasty anti-cut profile, and faster installation versus improvising with loose coils. In practice, diamond razor wire blends deterrence with durability—without screaming “military base” (well, not too loudly).

Vendor comparison (condensed)

| Vendor | Strengths | Notes |

|---|---|---|

| Hebei Yisizhe Manufacture (Group) Limited | Export-proven; welded mesh and concertina; custom apertures | Origin: Business building Tongxiang Shijiazhuang City Hebei Province; strong presence in Europe, South America, South Africa, SE Asia; many buyers mention timely delivery. |

| Generic Distributor (EU) | Local stock; quick dispatch | Often limited blade profiles; documentation quality varies by lot. |

| Local Fabricator (Regional) | Made-to-order sizes; site visits | Check coating standard and weld testing; pricing can swing. |

Customization and paperwork buyers ask for

Blade: BTO-22 is the crowd favorite; CBT-65 for maximum deterrence. Apertures: 75×150 mm diamond for anti-climb; 100×200 mm if you want lighter panels. Coatings: HDG for inland, SS 316 near salt. Useful docs: mill certs, EN 10244-2 coating data, ISO 9227 test summaries, and photos of weld samples. To be honest, a simple salt-spray graph goes a long way.

Quick case notes

Port perimeter, Europe: Swap from loose coils to welded diamond razor wire panels on posts at 2.4 m. Result: fewer tie failures, cleaner CCTV sightlines. Security manager said maintenance calls “dropped to almost zero.”

Solar farm, South America: 316 SS blades, Zn-Al core. After ≈1,000 h ISO 9227 lab checks, panels showed minor edge dulling but intact welds. Procurement lead told me the “predictable lead times beat local buys.”

Bottom line

If the spec reads welded mesh, don’t substitute coil tape last minute. Get blade profile, aperture, coating, and test data on the quote. And if you’re choosing vendors, prioritize verified exports, consistent coating reports, and realistic lead times. That’s how diamond razor wire projects avoid headaches.

Authoritative citations

- ASTM A641/A641M – Zinc-Coated (Galvanized) Carbon Steel Wire. https://www.astm.org/a0641_a0641m-19.html

- ASTM A653/A653M – Steel Sheet, Zinc-Coated (Galvanized). https://www.astm.org/a0653_a0653m-22.html

- EN 10244-2 – Steel wire and wire products, Non-ferrous metallic coatings. https://standards.iteh.ai/catalog/standards/cen/9a8d3a2a-

- ISO 9227:2017 – Corrosion tests in artificial atmospheres, Salt spray tests. https://www.iso.org/standard/63543.html

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025