Oct . 08, 2025 22:45 Back to list

Diamond Razor Wire: Anti-Climb, High-Tensile Security?

Diamond razor wire: the 2025 buyer’s guide from the field

I’ve walked more yards and perimeters than I can count, and the question keeps coming up: what’s the real story with diamond razor wire? Short answer: it’s not a gimmick. The diamond-pattern (often flat-wrap or clipped concertina to form diamond apertures) is gaining ground because it packs aggressive deterrence into a tidy, architect-friendly profile. Hebei Yisizhe Manufacture (Group) Limited—based in Business building, Tongxiang, Shijiazhuang City, Hebei Province—has been pushing this category hard, and to be honest, the uptake across Europe, South America, South Africa, and Southeast Asia doesn’t surprise me.

What’s trending

Three trends keep popping up: flat-wrap panels that look cleaner on city perimeters, hybrid coatings (galvanized + polymer) for coastal sites, and smarter install kits that cut labor by 20–30%. Many customers say they want “industrial, but not prison.” The diamond look bridges that gap—still nasty to climb, but tidier to the eye.

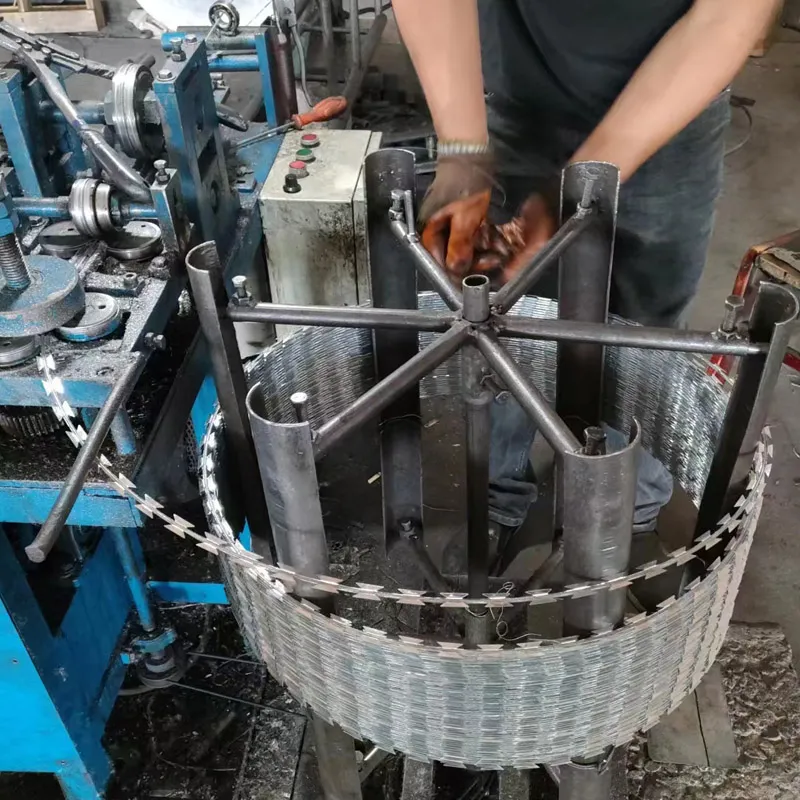

Materials and process flow (how it’s actually made)

- Substrate: high-tensile core wire ≈ 2.5 ± 0.1 mm, zinc-coated to EN 10244-2. Typical tensile 900–1200 MPa.

- Blade strip: galvanized steel or SS304/SS316 (≈0.5 ± 0.05 mm) slit and stamped into BTO/CBT profiles.

- Assembly: blades crimped around core, then formed to concertina coils; diamond geometry via flat-wrap or multi-clip spacing (≈3–5 clips per loop).

- Coatings: standard hot-dip galvanized (Z230–Z275 g/m²) or optional polyester topcoat (around 60–80 μm).

- Testing: tensile pull, clip shear, zinc mass, and accelerated corrosion (ASTM B117/ISO 9227). Service life in real-world use may vary, but 10–20 years is typical; coastal sites need upgraded coatings.

Product specification snapshot

| Blade type | Core wire | Coil Ø | Clips/loop | Finish | Weight/coil |

|---|---|---|---|---|---|

| BTO-22 | ≈2.5 mm HT | 450–600 mm | 3 | Galv Z275 | 7–9 kg |

| BTO-30 | ≈2.5 mm HT | 600–750 mm | 3–5 | Galv + Polyester | 9–12 kg |

| CBT-60 | ≈2.6 mm HT | 700–980 mm | 5 | SS304/316 | 12–15 kg |

Note: dimensions and weights are approximate; site-specific selections depend on fence height, risk level, and wind loading.

Applications and advantages

- Perimeters: logistics parks, power substations, data centers, airports, prisons, and border sections.

- Benefits: high delay factor, compact storage, faster install (flat-wrap), and—surprisingly—better visual compliance for urban planners.

- Typical spec: diamond razor wire on 2.4–3.6 m palisade or 358 mesh, tensioned with SS clips and anti-tamper fasteners.

Vendor comparison (quick take)

| Vendor | Coating options | Test data | Lead time | Certs |

|---|---|---|---|---|

| Yisizhe (Hebei) | Z275, SS304/316, polymer topcoat | B117/ISO 9227 500–1000 h | 10–20 days | ISO 9001 |

| Regional OEM | Z200–Z275 | B117 240–480 h | 20–30 days | ISO 9001 (varies) |

| Low-cost trader | Z120–Z200 | Limited/none | Uncertain | N/A |

Customization

Pick your poison: blade profile (BTO-18/22/30, CBT-60/65), coil diameter, clip count, finish, and color (RAL 6005, 7016, you name it). For salt-heavy air, I’d spec diamond razor wire with SS316 blades or a dual coat. Install kits with tension tools and stainless clips are worth the small premium.

Field notes and mini case studies

- South American port: polymer-coated diamond razor wire on 358 mesh; salt-spray spec 720 h; zero red rust at 18 months, per operator logs.

- Southeast Asia substation: BTO-30 flat-wrap reduced install time ≈25% compared with traditional concertina, according to contractor feedback.

- South Africa logistics park: CBT-60 atop palisade; incident reports dropped sharply—security team cited “visual deterrence” as a factor.

Standards, certifications, and the fine print

Look for compliance with EN 10244-2 (zinc), ASTM A641 (galv wire), and corrosion tests to ASTM B117/ISO 9227. Yisizhe reports ISO 9001-based QA; some projects request CE-related documentation for fence systems. Always cross-check coil tension, clip shear strength, and onsite earthing rules near electrified systems.

Actually, the best advice? Match threat level to spec, not the other way around. Overbuild coastal, streamline inland, and keep spares for emergency repairs.

References

- ASTM A641/A641M – Zinc-Coated (Galvanized) Carbon Steel Wire.

- EN 10244-2 – Steel wire and wire products: Non-ferrous metallic coatings on steel wire.

- ASTM B117 / ISO 9227 – Salt Spray (Fog) Testing for corrosion resistance.

- ISO 9001:2015 – Quality management systems.

- EN 10223 series – Steel wire products for fencing and netting (guidance for barbed/razor applications).

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025