Oct . 27, 2025 18:55 Back to list

Diamond Razor Wire: High-Security, Anti-Climb Fencing

Diamond Razor Wire: What’s Really Driving Demand (and How to Specify It Right)

If you work in perimeter security, you’ve heard the buzz around diamond razor wire. To be honest, the term gets used loosely. Most buyers mean high-tensile concertina or flat-wrap barbed tape installed in a diamond pattern along fences and walls. Semantics aside, the market’s growing fast—especially for export-grade coils that don’t rust out after a single monsoon season.

Industry snapshot

We’re seeing upgrades from conventional barbed wire to diamond razor wire across logistics parks, power substations, airports, and even data centers. Drivers? Rising insurance requirements, labor shortages (deterrence beats patrols), and better coatings that stretch service life to 10–20 years, real-world use may vary. Interestingly, many customers say flat-wrap looks cleaner and “less militarized” than large concertina coils—useful in urban projects.

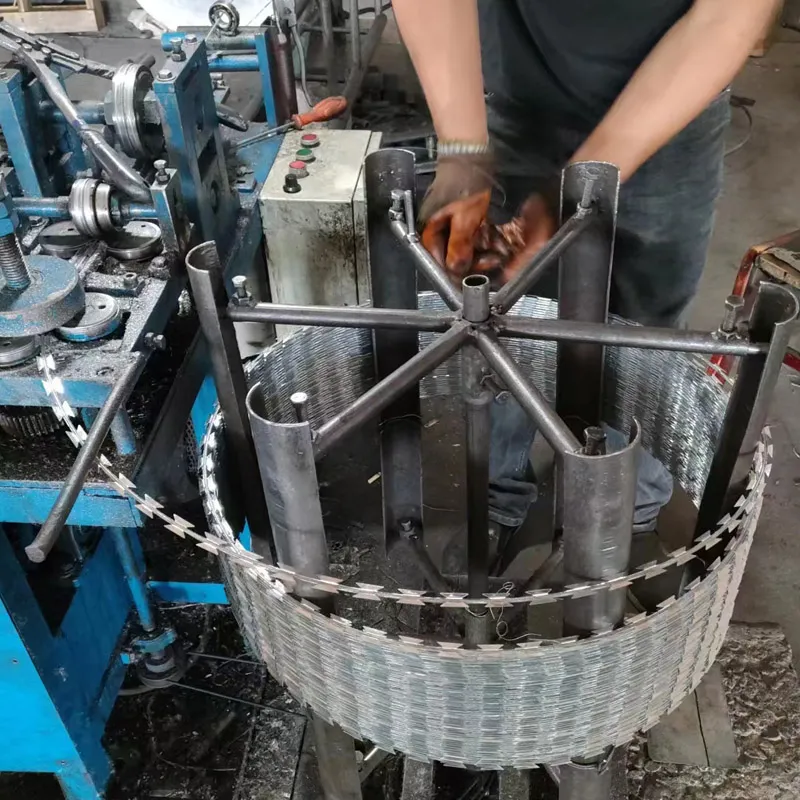

How it’s made (quick process flow)

- Materials: high-tensile core wire ≈ 2.5 mm (≥1200 MPa), blades stamped from galvanized steel (ASTM A653) or SS304/SS316.

- Methods: blade stamping → core wire pay-off → crimp/press bonding → coiling (concertina) or straightening (flat-wrap) → clip coupling.

- Coatings: heavy zinc 60–275 g/m² (EN 10244-2 Class D) or Zn-Al alloy; optional powder coat for visual blending.

- Testing: tensile (EN 10218), coating mass/uniformity, salt spray (ISO 9227), barb dimension checks (e.g., CBT-65, BTO-22 templates).

- Service life: around 10–25 years depending on coating, proximity to coast, and installation quality.

- Industries: utilities, transportation, warehousing, defense, correctional, mining, agriculture perimeters.

Representative specifications

| Parameter | Typical Value (≈) | Notes |

|---|---|---|

| Blade type | BTO-22, CBT-65 | Others on request |

| Core wire | 2.5 mm high-tensile ≥1200 MPa | Galv or stainless |

| Blade thickness | 0.5 ± 0.05 mm | ASTM A653 or SS304 |

| Coil diameter | 450 / 600 / 730 / 900 mm | Coverage varies with stretch |

| Coverage per coil | 8–12 m (≈) | Real-world use may vary |

| Finish | Hot-dip Zn / Zn-Al / Powder coat | RAL colors optional |

Where it fits

Use diamond razor wire above chain-link, palisade, or welded mesh panels; on walls; around rooftops; or as freestanding barriers with Y-posts. For neighborhoods and campuses, many specifiers pick flat-wrap because it hugs the fence and looks tidy.

Why buyers switch (and the data)

- Deterrence density: more cuts per meter than barbed wire.

- Strength: core wire resists cutting; clips reduce “peel back.”

- Corrosion: 300–600 h neutral salt spray (ISO 9227), depending on coating.

- Lifecycle: fewer replacements; lower total cost after year 3–5, in my experience.

Vendor comparison (quick take)

| Vendor | Blade Range | Coatings | Lead Time (≈) | Certs |

|---|---|---|---|---|

| Hebei Yisizhe Manufacture (Group) Limited | BTO-10~BTO-30, CBT-60/65 | Zn, Zn-Al, Powder, SS304/316 | 10–20 days | ISO 9001; EN/ASTM material compliance |

| Regional Brand A | BTO-22 focus | Zn only | 3–4 weeks | ISO 9001 (varies) |

| Global Brand B | BTO-18/22 | Zn, SS304 | 4–6 weeks | ISO 9001 |

Customization and origin

Blade geometry, coil diameter, clip spacing, and coatings are all customizable. Yisizhe ships from Business building Tongxiang Shijiazhuang City Hebei Province, and—actually this surprised me—lead times stayed stable even during peak season, with exports to Europe, South America, South Africa, Southeast Asia.

Field notes: quick case studies

- South Africa logistics yard: 900 mm concertina + palisade. Reported 70% drop in trespass within 3 months.

- Chilean substation: flat-wrap over mesh. Salt-fog tested 480 h; zero red rust on blades at 12 months.

- SEA warehouse cluster: powder-coated green diamond razor wire for aesthetic compliance; neighbors stopped complaining, which is half the battle.

Customer voice: “Install was faster than we planned. Coils came clipped and banded right—no tangle drama.”

Spec tips to avoid regrets

- Coating first: coastal jobs → Zn-Al or stainless; inland → heavy Zn is fine.

- Pick blade type to match threat: CBT-65 for high-risk; BTO-22 for balanced cost/impact.

- Call out standards in the RFQ: ASTM A653 for blade sheet; EN 10244-2 for coating class; ISO 9227 hours for corrosion baseline.

- Don’t skimp on clips and posts—most failures start at supports, not the wire.

Certifications and compliance

ISO 9001 factory QA, material test reports on request, and batch-level tensile/coating logs. Safety note: install diamond razor wire per local fence codes (e.g., height setbacks) to avoid legal headaches.

Authoritative citations

- ASTM A653/A653M – Steel Sheet, Zinc-Coated (Galvanized).

- EN 10244-2: Steel wire and wire products – Zinc or zinc alloy coatings.

- ISO 9227: Corrosion tests in artificial atmospheres – Salt spray tests.

- ISO 9001: Quality management systems – Requirements.

- ASTM A121: Zinc-Coated (Galvanized) Steel Barbed Wire.

-

Pre Cut Wire - Straightened, Deburred, Custom Lengths

NewsNov.17,2025

-

Binding Wire for Sale - Durable, Rust-Resistant, Bulk Deals

NewsNov.17,2025

-

Field Fencing for Horses – Safe, Durable, Easy Install

NewsNov.17,2025

-

Euro Fence Factory: Durable, Custom Euro Style Fences

NewsNov.17,2025

-

Euro Fence Factory: Durable OEM Panels, Direct Pricing

NewsNov.17,2025

-

Chain Link Fence Suppliers | Galvanized, Factory-Direct

NewsNov.11,2025