Aug . 13, 2024 12:23 Back to list

Welded wire mesh – advantages and applications

Welded wire mesh – advantages and applications

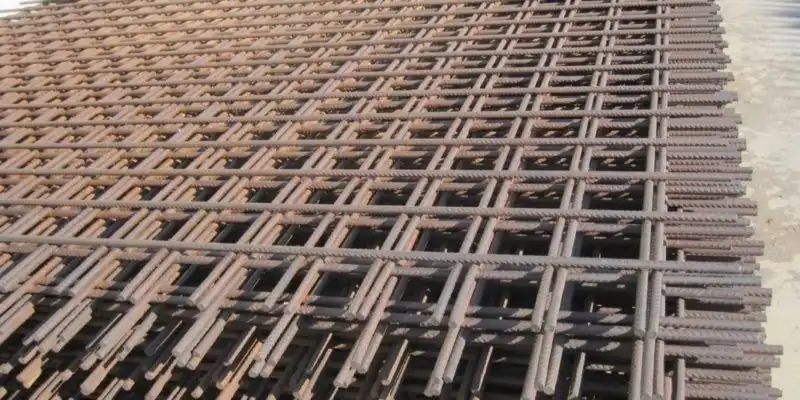

The application of factory cut & bend reinforcement has foreseen adaptability owing to the increased need for speed and better quality. Welded wire mesh has been quite useful in addressing this issue. Welded wire mesh is a great reinforcement component for concrete structures. It is an electric fusion welded prefabricated joined grid consisting of a series of parallel longitudinal wires with accurate spacing welded to cross wires at the required spacing. Welded wire mesh is a steel reinforcement material in concrete. The mesh is used for replacing the traditional “cut & bend” and placing of steel thermo-mechanically treated bars. These are made from reinforcing wire, located in two mutually perpendicular directions and connected at the intersection of resistance spot welding. Welded Wire Mesh is a need of the hour in developing countries like India.

Projects must adopt this technique owing to space constraints in setting up cutting, bending and storage yards at the site and speed up the installation process. Provisions exist in the Indian Standards that support the use of Welded Wire Mesh through advice regarding their design and detailing. The welded wire mesh is a metal screen that is made up of low carbon steel wire or stainless steel wire. It is available in various sizes and shapes. The welded wire mesh can be customized for various shapes. Metal can be equipped with special coatings that improve the surfaces to be resistant to chemicals and other corrosive substances.

Pvc Coated Welded Wiremesh

Advantages of welded wire mesh

Welded wire mesh is made of high-quality low carbon iron wire, through a fully automated computer-controlled welding machine. It has several advantages, a few of them are explained below.

- Improved site efficiency & productivity with reduced reliance on manpower on-site.

- The chance of improper bending of bars is reduced since bending machines bend the mat as a single unit.

- Provides the exact size of reinforcement where needed through variable bar size and spacing.

- Welded Wire Mesh can be placed in position relatively faster as compared to placing individual bars and tying them in place. This results in a reduced cycle time of slab casting.

- Reduced construction cost due to enhanced speed of construction.

- Designers can use thinner bars at closer spacings achieving efficient stress transfer to concrete with much smaller crack widths, resulting in better-finished surfaces.

- Welded Wire Mesh can be manufactured from rolls instead of stock length bars, thus minimizing the wastage.

- Welded Wire Mesh requires a lesser storage area at the site.

- Cutting & bending in the factory eliminates the need to rebar yard at site.

- Factory production is inherently safer as compared to bending rebar at the site.

- Faster erection time.

- Removes reinforcement placement.

- Mesh stays where you put it and has excellent adherence to concrete.

- Easy unloading and installation at the working site.

Application of welded wire mesh:

Welded wire mesh is also used for other purposes, such as:

- Building Welded mesh reinforcement is widely used for the reinforcement of concrete structures. In this case, inside poured concrete forms (under the slab, frame foundation slab is poured) laid welded reinforcing mesh, which serves to increase the strength of formed concrete structures.

- Making frames.

- Reinforcement of road surfaces or parking areas so welded reinforcing mesh called road reinforcing mesh grid.

- Manufacture of various fences.

- Used as Masonry mesh.

- Used as a coal mine supporting mesh for coal mine roadway support.

Application of welded wire mesh

There are newer innovations and advancements regarding welding technology. Remote welders allow for improved productivity and less downtime. On-site repairs and alterations are highly sought after and manufacturers that provide these services are recognized for their ability to adapt to the changing needs of the market. There are various types of welded wire mesh types each can be used as per need and requirement, which we will discuss in an upcoming article.

-

Weather Resistance Properties of Quality Roofing Nails

NewsAug.01,2025

-

How Galvanised Iron Mesh Resists Corrosion in Harsh Environments

NewsAug.01,2025

-

Creative Landscaping Uses for PVC Coated Wire Mesh Panels

NewsAug.01,2025

-

Common Wire Nail Dimensions and Their Specific Applications

NewsAug.01,2025

-

Choosing the Right Welded Wire Sheets for Agricultural Fencing

NewsAug.01,2025

-

Anti - Climbing Features of Razor Wire Barriers

NewsAug.01,2025