ธ.ค. . 03, 2024 19:05 Back to list

Choosing the Right Fittings for Hydraulic Hose Crimping Applications

Understanding Hydraulic Hose Crimp Fittings

Hydraulic systems are the lifeblood of many industries, powering machinery and equipment with remarkable efficiency. At the heart of these systems are hydraulic hoses and their connection points, which are critical for maintaining the integrity and performance of hydraulic circuits. This article delves into hydraulic hose crimp fittings, exploring their function, types, and importance within hydraulic systems.

What are Hydraulic Hose Crimp Fittings?

Hydraulic hose crimp fittings are specialized components used to create secure, leak-proof connections between hydraulic hoses and equipment. The term crimping refers to the process of deforming the fitting and the end of the hose to create a tight, permanent bond. This method is preferred in numerous applications for its reliability and strength, ensuring that the connections can withstand high pressures and varied environmental conditions.

Function and Importance

The primary function of hydraulic hose crimp fittings is to facilitate the transfer of hydraulic fluid from one component to another while preventing leaks that could hinder performance or cause failures. A leak can not only compromise efficiency but can also pose safety risks, leading to environmental damage or equipment malfunctions.

Moreover, crimp fittings play a vital role in maintaining the dynamic nature of hydraulic systems. For systems that operate under high pressure—often exceeding thousands of psi—having robust connections is crucial. Crimp fittings provide a strong interface that is resistant to the vibration and movement commonly found in heavy machinery operations.

Types of Crimp Fittings

Hydraulic hose crimp fittings come in various types, each tailored for specific applications. Generally, the fittings can be categorized into male and female types, and they come in different shapes—such as straight, elbow, and tee—to suit various installation requirements. The choice of fitting depends on multiple factors, including hose material, size, and the operational environment.

hydraulic hose crimp fittings

1. Standard Crimp Fittings These basic fittings are designed for general purposes and can be easily used in various hydraulic applications. They are suitable for moderate pressure and help in maintaining flexibility.

2. Heavy-Duty Crimp Fittings For applications that demand higher durability—such as construction, agriculture, and mining—heavy-duty fittings are manufactured from stronger materials, enabling them to withstand extreme pressures and temperature ranges.

3. Specialized Fittings Some fittings are designed for specific applications, such as those requiring chemical resistance or specialized exposing conditions, such as high-temperature operations or marine environments.

Installation and Maintenance

Proper installation of hydraulic hose crimp fittings is crucial to ensure performance and reliability. Typically, a crimping machine is used, which compresses the fittings onto the hose at a precise rate. This process requires skill and should adhere to manufacturer guidelines to ascertain that the correct amount of pressure is applied during crimping.

Regular maintenance checks are also necessary. Users must inspect for signs of wear or damage, such as leaks, bulging, or discoloration of the hoses and fittings. Preventive maintenance helps identify potential issues before they escalate, ensuring the longevity and efficiency of hydraulic systems.

Conclusion

Hydraulic hose crimp fittings are indispensable components in hydraulic systems, providing secure, reliable connections that ensure optimal performance under various conditions. With various types catering to different applications, understanding their function and proper maintenance can significantly influence the efficiency and safety of hydraulic machinery. As industries continue to evolve, so too will the technology surrounding hydraulic systems, but the fundamental role of crimp fittings will always remain critical.

-

Weather Resistance Properties of Quality Roofing Nails

NewsAug.01,2025

-

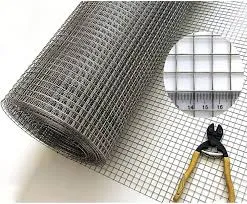

How Galvanised Iron Mesh Resists Corrosion in Harsh Environments

NewsAug.01,2025

-

Creative Landscaping Uses for PVC Coated Wire Mesh Panels

NewsAug.01,2025

-

Common Wire Nail Dimensions and Their Specific Applications

NewsAug.01,2025

-

Choosing the Right Welded Wire Sheets for Agricultural Fencing

NewsAug.01,2025

-

Anti - Climbing Features of Razor Wire Barriers

NewsAug.01,2025