ตาข่ายลวดเชื่อมเคลือบพีวีซี

ตาข่ายลวดเชื่อมเคลือบพีวีซี

Finish: PVC coated

Colors: Green, blue, white, or other colors at customer request.

Packing: in waterproof paper in rolls. Custom packing is available at request.

Benefits of PVC-Coated Welded Wire Fencing

PVC-coated welded wire fencing offers a range of benefits that make it an ideal choice for both residential and commercial applications. One of the primary advantages is its durability. The PVC coating provides an added layer of protection against the elements, significantly enhancing the corrosion resistance of the wire mesh. This makes it highly suitable for outdoor applications, especially in areas with high humidity, rain, or extreme temperatures. Unlike traditional galvanized wire, which can rust and deteriorate over time, PVC-coated wire can withstand harsh weather conditions, ensuring a longer lifespan with minimal maintenance.

Another key benefit is aesthetic appeal. PVC-coated welded wire fencing is available in a variety of colors, which allows it to blend seamlessly into different environments. Whether it's a garden, farm, or commercial property, the coating enhances the fence's visual appearance, making it more attractive than basic metal fencing. The smooth, uniform coating also provides a cleaner look and eliminates the sharp edges that can be present in uncoated wire, making it safer for both people and animals.

PVC-coated welded wire also offers excellent strength and security. The welded construction ensures that the mesh is robust, resistant to stretching, and can effectively keep out intruders or animals. It's often used in security applications, such as perimeter fencing for industrial sites, parks, or schools. Additionally, its versatility makes it suitable for a variety of uses, from livestock enclosures to garden fencing.

Finally, low maintenance is another significant advantage. The PVC coating makes the fencing easy to clean and prevents the need for frequent painting or rust prevention treatments. This reduces long-term upkeep costs and effort, making PVC-coated welded wire fencing a cost-effective solution for many projects.

Applications of PVC-Coated Welded Wire

1. Security Fencing

PVC-coated welded wire is frequently used in security fencing for both residential and commercial properties. The PVC coating adds an extra layer of protection against corrosion, ensuring the fence withstands harsh weather conditions without deteriorating. Its strength and resistance to tampering make it ideal for high-security areas such as industrial facilities, military bases, prisons, and airports. The welded wire design also prevents easy climbing, enhancing security.

2. Agricultural Fencing

In agriculture, PVC-coated welded wire is commonly used to create strong and durable livestock enclosures. The coating prevents rust and corrosion from exposure to the elements, making it a great choice for protecting cattle, horses, and other livestock. The wire's strength ensures that it can withstand the pressure of animals pushing against it, while the smooth coating is safer for the animals compared to uncoated wire.

3. Garden and Landscape Fencing

PVC-coated welded wire is also a popular choice for garden fencing due to its aesthetic appeal and functional qualities. Available in various colors, it can blend into the landscape, offering both protection and decoration. It’s used to create vegetable garden enclosures, flower bed borders, and plant trellises, protecting plants from pests and small animals while maintaining an attractive appearance.

4. Pet and Animal Containment

For pet containment, PVC-coated welded wire provides a safe and durable solution. It is used in the construction of dog kennels, chicken coops, rabbit hutches, and aviaries. The wire's smooth finish prevents pets from getting injured, while the coating protects against weathering, ensuring long-lasting durability.

5. Temporary Fencing

PVC-coated welded wire is often used for temporary fencing at construction sites, events, or public spaces. Its portability, ease of installation, and resistance to corrosion make it ideal for short-term use where security or crowd control is needed.

6. Erosion Control and Landscaping

In areas prone to soil erosion, PVC-coated welded wire is used in erosion control applications. The wire can be used to reinforce gabion baskets or as part of retaining walls, helping to stabilize soil and prevent runoff. Additionally, it’s employed in landscaping projects for creating decorative fencing or as a support structure for climbing plants.

7. Wildlife and Barrier Fencing

PVC-coated welded wire is also used in wildlife management to create barriers and enclosures that prevent animals from entering certain areas. It is commonly used to protect gardens, orchards, and crops from wildlife such as deer, rabbits, or small rodents. Additionally, it can be used to fence off wildlife habitats or create sanctuaries for endangered species, where the smooth, durable wire provides both protection and safety.

8. Sports Field Fencing

In sports facilities, PVC-coated welded wire is used to build strong and durable sports field fencing. It is often employed in tennis courts, soccer fields, baseball diamonds, and basketball courts. The wire fence keeps balls within the playing area and provides a clear, strong barrier around the field while being resistant to outdoor elements.

9. Decorative and Architectural Uses

Due to its customizable appearance, PVC-coated welded wire is increasingly being used in architectural designs and decorative projects. It is used to create fence panels, screening, or railings that blend seamlessly into urban landscapes, public spaces, or modern buildings. The PVC coating adds both a protective and a decorative element to the wire mesh, enhancing its visual appeal.

10. Construction and Industrial Applications

PVC-coated welded wire is used in the construction industry for reinforcing concrete structures, such as concrete slabs or flooring, where the wire mesh helps distribute the load and prevent cracks. Additionally, it is used in industrial applications like storage cages and partition fences, which require strong and durable barriers to separate goods, materials, or equipment.

11. Transportation and Infrastructure

PVC-coated welded wire is sometimes used for barriers and fencing along roadways, railways, and airports. It helps control access to restricted areas and ensures the safety of both vehicles and pedestrians. Additionally, the wire’s resistance to rust and wear makes it a reliable option for high-traffic environments where durability is essential.

PVC-Coated Welded Wire vs. Galvanized Wire Mesh

PVC-coated welded wire mesh is celebrated for its durability and aesthetic appeal. The PVC coating adds a layer of protection against rust and corrosion, making it an excellent choice for outdoor environments. This type of mesh comes in a variety of colors, allowing you to match it with your landscape or building decor. Additionally, the welded construction offers enhanced strength, making it ideal for applications where security is a concern, like fencing for livestock or garden enclosures.

On the other hand, galvanized wire mesh is known for its robust performance and cost-effectiveness. Galvanization involves coating the wire in a layer of zinc, which provides protection against rust. While it may not offer the same range of colors as PVC-coated welded wire mesh, galvanized mesh is highly durable and can withstand harsh weather conditions, making it suitable for various commercial and industrial uses.

When deciding between PVC-coated welded wire mesh and galvanized wire mesh, consider the specific requirements of your project. If aesthetic appeal and additional rust protection are priorities, the PVC-coated option may be the best choice. However, if you are looking for a more economical solution that still provides great durability, galvanized wire mesh could be the right fit.

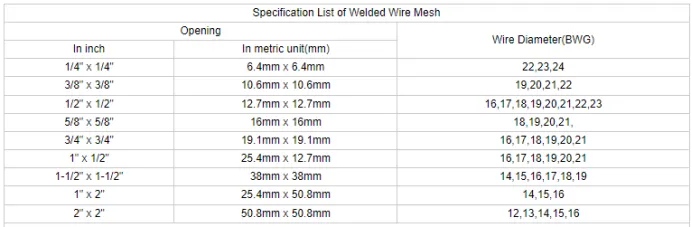

PVC Coated Welded Wire Mesh Specification Guide: From ¼" Mesh to 2"×2" Grid Details

Choosing the right specifications for PVC coated welded wire mesh is key to optimizing performance for applications ranging from security fencing to agricultural enclosures. YISIZHE, a leading pvc coated wire mesh manufacturers, offers a comprehensive range of PVC coated welded wire mesh with precise dimensions and customizable features. Below is a detailed breakdown of key specifications to help you select the perfect solution.

1. Mesh Opening Sizes: Tailored to Your Needs

Our PVC coated wire mesh is available in multiple mesh sizes, each designed for specific uses:

¼"×¼" (6mm×6mm): Fine mesh ideal for pet cages, insect screens, or plant protection, preventing small animals or pests from passing through.

½"×½" (13mm×13mm): Versatile for poultry fencing, rabbit hutches, and garden borders, balancing security with visibility.

1"×1" (25mm×25mm): Common for livestock barriers, chain link fence reinforcement, and industrial partitions, offering robust strength for medium-duty applications.

2"×2" (50mm×50mm): Heavy-duty mesh suitable for large animal enclosures, construction site fencing, or storage rack dividers, capable of withstanding high impact.

2. Wire Gauge (BWG) & Thickness

Wire gauge determines the mesh’s rigidity and load-bearing capacity:

BWG 24 (0.56mm): Thin, flexible wire for light-duty uses like decorative fencing or indoor partitions.

BWG 20 (0.91mm): Medium thickness, perfect for garden fencing, chicken coops, and general-purpose PVC coated wire mesh panels.

BWG 16 (1.6mm): Thick, durable wire for heavy-duty applications such as security fences, industrial cages, or retaining wall reinforcement.

3. PVC Coating: Protection & Aesthetics

All our PVC coated wire mesh features a 0.2–0.4mm PVC layer, providing:

Corrosion Resistance: 10–15 years of outdoor durability, ideal for humid, coastal, or chemically aggressive environments.

Color Options: Standard colors include green, black, and white, with custom colors available for landscape integration (e.g., green mesh blending with garden foliage).

UV Resistance: Reduces fading and brittleness, ensuring long-term visual and structural integrity.

4. Panel Dimensions & Customization

Standard Rolls: Available in widths from 3ft (0.9m) to 6ft (1.8m) and lengths up to 100ft (30m), perfect for quick installation.

Custom Panels: Tailor-made PVC coated wire mesh panels in specific sizes for projects like window guards, machine shields, or architectural screens.

Packaging: Shipped in waterproof paper rolls or pallets to prevent damage during transit—ideal for PVC coated wire mesh for sale worldwide.

Why Choose YISIZHE’s PVC Coated Welded Wire Mesh?

Precision Manufacturing: Automated welding ensures uniform mesh sizes and strong joints, eliminating loose wires.

Full Customization: Adjust mesh size, wire gauge, coating thickness, and color to match your project’s unique requirements.

Quality Assurance: Complies with ISO 9001 standards, with each batch tested for coating adhesion and wire tensile strength.

Whether you need fine mesh for pet enclosures or heavy-duty panels for industrial security, YISIZHE’s PVC coated welded wire mesh delivers reliability, versatility, and aesthetic appeal. Our team of experts is ready to help you select the right specifications or create a custom solution. Contact us today to explore our PVC coated wire mesh for sale and experience the difference of manufacturer-direct quality.

Installation and Maintenance Guide for PVC Coated Welded Wire Mesh: From Site Preparation to Cleaning

Proper installation and maintenance of PVC coated welded wire mesh are key to maximizing its lifespan and performance in applications like fencing, enclosures, and security barriers. As a leading PVC coated wire mesh manufacturer, YISIZHE provides this comprehensive guide to help you install our PVC coated wire mesh with ease and keep it in optimal condition for years.

Step 1: Site Preparation & Measurement

Assess the Area: Clear the installation site of debris, weeds, or uneven terrain to ensure a stable base. For fencing, mark post positions (spaced 6–8ft apart for PVC coated wire mesh panels) using stakes or spray paint.

Measure Twice, Cut Once: Calculate the required mesh length and width, adding 3–5 inches for overlap and fastening. Use heavy-duty wire cutters to trim pvc coated welded wire mesh—the PVC layer prevents fraying, but wear gloves to protect hands.

Step 2: Secure the Mesh

For Fencing/Gates: Attach mesh to wooden/metal posts using galvanized U-clips or zip ties, starting from the bottom to keep it taut. Overlap adjacent panels by 2–3 inches and secure with wire ties for seamless coverage.

For Wall/Window Guards: Use screws with rubber washers to mount PVC coated wire mesh directly to walls, ensuring the mesh is flat and free of tension to avoid coating damage.

Heavy-Duty Applications: For industrial partitions or animal enclosures, reinforce corners with angle brackets and use self-tapping screws every 12–18 inches for maximum stability.

Step 3: Finishing Touches

Edge Protection: Cover sharp cut edges with PVC edge trim or rubber guards to prevent injury and protect the coating from abrasion.

Gate Hardware: Install hinges and latches rated for outdoor use to maintain the mesh’s weather resistance—YISIZHE’s PVC coated wire mesh pairs well with stainless steel fittings for coastal or high-moisture areas.

Maintenance Tips for Longevity

Routine Cleaning: Wash the mesh quarterly with mild soapy water and a soft brush to remove dirt, leaves, or salt buildup (critical for coastal installations). Avoid high-pressure washers, which may damage the PVC layer.

Coating Inspection: Check annually for scratches or peeling. Small damages can be repaired with PVC patch kits; larger areas may require replacing the panel to prevent underlying wire corrosion.

Environmental Adaptation: In regions with heavy snow or ice, brush off accumulations promptly to reduce weight stress. For agricultural use, rinse off animal waste regularly to prevent acidic corrosion.

Why YISIZHE’s Mesh Simplifies Installation & Maintenance

Pre-Cut Panels: Order PVC coated wire mesh panels in custom sizes to minimize on-site cutting, available in standard widths (3–6ft) and lengths up to 100ft.

Durable Coating: Our 0.2–0.4mm PVC layer is UV-stabilized and scratch-resistant, reducing the need for frequent repairs compared to uncoated meshes.

Expert Support: As PVC coated wire mesh manufacturer, we provide installation diagrams and material recommendations for every project, from garden fencing to industrial security.

By following these steps, your PVC coated welded wire mesh will remain a secure, low-maintenance solution for decades. Whether you’re installing a backyard fence or reinforcing a commercial facility, YISIZHE’s high-quality mesh and straightforward guidance ensure a hassle-free process. Explore our PVC coated wire mesh for sale today and enjoy the peace of mind that comes with professional-grade durability.

Pvc Coated Wire Mesh Sizes

ข่าวที่เกี่ยวข้อง