okt . 22, 2024 12:21 Back to list

Welded Wire Mesh Cost Analysis for Various Applications

Understanding Welded Wire Mesh Prices Factors and Market Insights

Welded wire mesh is an essential component in various construction, agricultural, and industrial applications. This versatile product consists of wire strands that are welded at their intersections, forming a grid-like structure that offers strength, durability, and flexibility. From reinforcing concrete to creating fencing and livestock enclosures, welded wire mesh serves numerous purposes. However, many people are often curious about the pricing of welded wire mesh. Understanding the factors influencing these prices can help consumers make informed decisions.

1. Raw Material Prices

The primary factor affecting the price of welded wire mesh is the cost of raw materials. Typically, the mesh is made from steel, and fluctuations in steel prices have a direct impact on welded wire mesh costs. The global steel market is influenced by various factors, including mining, production costs, and international trade policies. An increase in demand or a decrease in supply can lead to higher prices. Additionally, the type of steel used (galvanized, stainless, or mild steel) can also affect the overall costs, as premium materials carry higher price tags.

2. Thickness and Wire Diameter

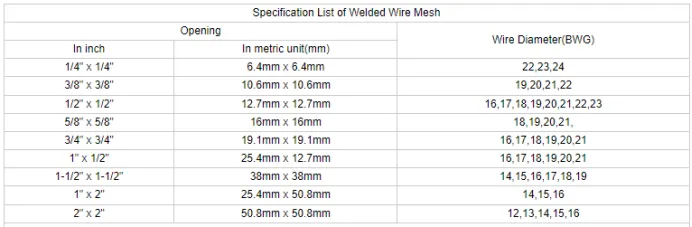

The thickness of the wire and the size of the mesh openings significantly influence the price. Thicker wires are typically more expensive due to the increased amount of material used. Similarly, larger mesh openings can reduce the amount of wire needed, potentially lowering costs. On the other hand, smaller openings require more precise manufacturing processes, which can increase production costs. As a result, buyers must evaluate their specific needs against available products and their corresponding prices.

3. Coating and Protection

Welded wire mesh can be coated or treated to enhance its durability and resistance to environmental factors such as corrosion. Common types of coatings include galvanization, PVC coating, and epoxy finishes. Products that are galvanized or coated tend to be more expensive than uncoated options due to the additional processing involved. For example, galvanized welded wire mesh is popular for outdoor applications as it withstands moisture and other corrosive elements, making it a worthwhile investment despite its higher initial cost.

welded wire mesh price

The methods used in manufacturing welded wire mesh also impact pricing. Different production techniques can lead to variations in quality and durability, which translate into different price points. Typically, mesh that undergoes more stringent quality control and advanced manufacturing processes will be priced higher. Additionally, customized sizes and specifications can lead to increased costs due to the added labor and material requirements.

5. Regional Market Variations

Prices for welded wire mesh can vary based on geographic location. In areas where industrial production is booming, demand for construction materials like welded wire mesh may push prices higher. Conversely, in regions with less activity, prices may be more competitive. Moreover, local suppliers may have different overhead costs, including transportation, warehousing, and labor, which can also influence final pricing.

6. Supply Chain Factors

The ongoing global supply chain challenges have also affected the prices of welded wire mesh. Disruptions due to the pandemic, changes in trade regulations, and fluctuations in transportation costs can lead to inventory shortages and increased costs. If suppliers face difficulties obtaining raw materials or delivering products efficiently, consumers may see price increases.

7. Comparison Shopping

Given the multitude of factors influencing the price of welded wire mesh, it’s essential for buyers to engage in comparison shopping. Prices can vary significantly between manufacturers and suppliers. By gathering multiple quotes and considering quality, service, and warranty options, consumers can find the best value for their needs.

Conclusion

Welded wire mesh is a critical component in various industries, and its pricing reflects a range of factors including raw material costs, product specifications, manufacturing processes, regional market conditions, and supply chain dynamics. While price is an important consideration, it's equally vital to assess quality and suitability for specific applications. By understanding these factors, consumers can make informed choices when purchasing welded wire mesh, ensuring they receive the best product for their investment.

-

Weather Resistance Properties of Quality Roofing Nails

NewsAug.01,2025

-

How Galvanised Iron Mesh Resists Corrosion in Harsh Environments

NewsAug.01,2025

-

Creative Landscaping Uses for PVC Coated Wire Mesh Panels

NewsAug.01,2025

-

Common Wire Nail Dimensions and Their Specific Applications

NewsAug.01,2025

-

Choosing the Right Welded Wire Sheets for Agricultural Fencing

NewsAug.01,2025

-

Anti - Climbing Features of Razor Wire Barriers

NewsAug.01,2025