Ravindra Kumar

Site Civil Engineer, India

The galvanized steel wire mesh is made of high-quality low-carbon steel wire, which is processed and formed by automatic, precise and accurate mechanical equipment spot welding. The surface treatment of the welded wire mesh is galvanized, and it is produced in conventional British standards.

Svetsat trådnät är det mest populära materialet.

Den kommer inte att lossna även om den skärs av eller under tryck. Den har den starkaste anti-korrosionsprestanda i hela järnskärmen, och det är också en av de mest använda järnskärmarna.

Galvanized steel wire mesh is widely used in industry, agriculture, construction, transportation, mining and other industries. Such as machine guards, livestock fences, garden fences, window guards, passage fences, poultry cages, egg baskets and home office food baskets, waste baskets and decoration. It is mainly used for general building exterior walls, concrete pouring, high-rise residential buildings, etc.

Det spelar en viktig strukturell roll i värmeisoleringssystemet. Under konstruktionen placeras den varmförzinkade el-svetsade gallerpolystyrenskivan inuti den yttre formen på den yttervägg som ska gjutas. , den yttre isoleringsskivan och väggen överlever på en gång, och isoleringsskivan och väggen integreras till ett efter att formen har tagits bort.

Galvanised iron wire mesh is excellent corrosion resistance and oxidation resistance. So it is one popular material in buiding construction, protection system, filtration, agriculture, and so on.

Finish:electro galvanized and hot-dipped galvanized

Förpackning: i vattentätt papper i rullar. Anpassad förpackning tillgänglig på begäran.

Galvanized welded wire mesh is a cornerstone material in construction, agriculture, and industrial applications, valued for its strength, versatility, and corrosion resistance. At YISIZHE, we specialize in manufacturing high-quality galvanized welded wire mesh by integrating premium materials and advanced processes, ensuring optimal performance even in harsh environments.

Core Materials: Foundation of Durability

1. Low-Carbon Steel Wire Substrate

Our galvanised iron wire mesh starts with low-carbon steel wire, chosen for its balanced ductility and tensile strength. This base material allows the mesh to withstand bending, cutting, or pressure without deforming—critical for applications like concrete reinforcement or livestock fencing.

2. Zinc Coating: The First Line of Defense

We offer two primary galvanization processes:

Electro-Galvanization: A thin zinc layer (10–30g/m²) applied via electrolysis, ideal for galvanized mesh panels used in dry, indoor, or mildly corrosive environments (e.g., garden fences, poultry cages).

Hot-Dip Galvanization: Immersing the mesh in molten zinc to form a thick, rugged layer (60–300g/m²), providing superior corrosion resistance for outdoor or harsh conditions (e.g., coastal projects, industrial partitions).

Welding Process: Structural Integrity Meets Precision

Our welded mesh galvanised wire panels are produced using automated resistance welding, fusing intersections at high temperatures to create solid, uniform joints. This process ensures:

No Loose Wires: weld points are stronger than the wire itself, preventing gaps that could compromise security or structural stability.

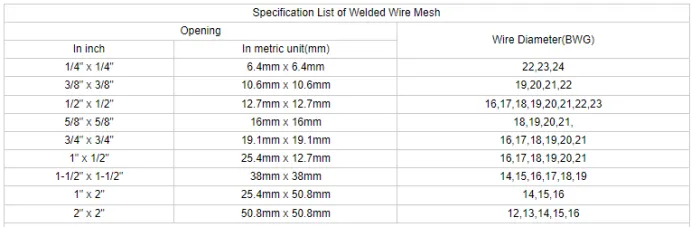

Consistent Mesh Sizes: From ¼"×¼" for fine filtration to 2"×2", our precision welding maintains exact specifications, critical for applications like concrete reinforcement or machine guards.

Corrosion Resistance: How Galvanization Works

The zinc coating on galvanised steel mesh panels acts as a sacrificial layer, oxidizing before the underlying steel to protect it from rust.

Hot-Dip Galvanized Mesh: Offers 10–15 years of outdoor durability (up to 20+ years in less corrosive areas), making it ideal for galvanized steel wire mesh used in infrastructure projects like highway barriers or building facades.

Electro-Galvanized Mesh: Suitable for short-term or indoor use, such as galvanised steel wire mesh sheets in storage racks or partition walls.

For extreme environments, we also provide PVC-coated galvanized mesh, adding a 0.2–0.4mm polymer layer to resist UV rays, moisture, and chemical exposure.

YISIZHE’s Manufacturing Excellence

As trusted galvanized welded wire mesh manufacturers, we prioritize:

Material Traceability: Sourcing steel from certified mills and testing zinc coating thickness to ensure compliance with ASTM/AISI standards.

Custom Solutions: Tailoring wire gauges (12–24 BWG), mesh sizes, and surface treatments to meet unique project needs—whether for a small-scale galvanized mesh garden fence or a large industrial galvanised steel wire mesh installation.

Cost-Effective Quality: Our automated production lines balance precision with affordability, delivering galvanized wire mesh for sale that offers long-term value without compromising on performance.

From agricultural fencing to high-rise construction, YISIZHE’s galvanized welded wire mesh combines robust materials, precise welding, and superior galvanization to deliver lasting corrosion resistance. Contact us today to explore our range or request a customized quote—engineered to exceed your expectations in durability and reliability.

Galvanized welded wire mesh is a pivotal material in modern construction, celebrated for its ability to enhance structural integrity, durability, and safety across diverse engineering projects. YISIZHE’s premium galvanized welded wire meshes are designed to meet the rigorous demands of construction environments, delivering both functional and protective benefits.

1. Concrete Reinforcement: Strengthening Foundation Structures

In concrete applications, galvanised iron wire mesh acts as a vital reinforcement layer, distributing tensile forces to prevent cracking and improve load-bearing capacity.

Foundation & Slab Construction: Placed within concrete slabs, driveways, or basement floors, its uniform grid structure (common mesh sizes: 1"×1" to 2"×2") enhances resistance to thermal expansion and mechanical stress.

Masonry Support: Used in brick or block walls, galvanised steel mesh panels stabilize mortar joints, reducing the risk of displacement in seismic or high-wind zones.

2. Exterior Insulation & Finish Systems (EIFS)

For energy-efficient buildings, galvanized mesh plays a critical role in exterior insulation systems:

Insulation Reinforcement: Installed over foam insulation boards, it provides a secure base for render or stucco finishes, ensuring long-term adhesion and impact resistance.

Weather Protection: The corrosion-resistant zinc coating of galvanized steel wire mesh shields against moisture and UV damage, extending the lifespan of exterior cladding in harsh climates.

3. Safety & Security in Building Envelopes

Window & Balcony Guards: Fine-mesh galvanised steel wire mesh sheets (e.g., ¼"×¼" to ½"×½") serve as fall-protection barriers while maintaining visibility, ideal for residential and commercial high-rises.

Fire Resistance Enhancement: When integrated into partition walls or ceilings, the mesh reinforces gypsum boards, delaying fire spread and improving structural integrity during emergencies.

4. Structural Stability in Renovation Projects

During retrofitting or seismic upgrades, welded mesh galvanised wire panels offer a cost-effective solution:

Crack Repair: Applied over existing walls with damaged plaster, the mesh redistributes stress to prevent further cracking.

Load Transfer: In reinforced concrete structures, it enhances the bond between old and new materials, ensuring seamless load distribution.

Why YISIZHE’s Galvanized Welded Wire Mesh Stands Out

Precision Engineering: Our galvanized welded wire mesh features resistance-welded joints that are stronger than the wire itself, ensuring no loose intersections in high-stress applications.

Customizable Specifications: Choose from wire gauges (12–24 BWG), mesh sizes, and galvanization types (electro or hot-dip) to match project requirements—whether for a small-scale renovation or a large commercial build.

Compliance with Standards: Meet or exceed ASTM A641 and ISO 1461 standards for zinc coating thickness, guaranteeing long-term performance in concrete, insulation, and safety systems.

From reinforcing foundations to safeguarding building exteriors, YISIZHE’s galvanized welded wire mesh is an indispensable asset in construction. Its unique combination of strength, corrosion resistance, and adaptability makes it the preferred choice for engineers and contractors worldwide. Contact us today to discuss how our galvanised steel wire meshes can elevate the safety and durability of your next project.

Galvanized mesh panels have become a staple in fencing solutions due to their durability, versatility, and cost-effectiveness. Whether for a home perimeter, commercial property, warehouse compound, or even park enclosures, the robustness of galvanized steel wire mesh stands out. Galvanization involves coating steel with a layer of zinc, effectively protecting it from corrosion caused by exposure to moisture or harsh environments. This makes the panels a perfect long-term investment for outdoor installations that must withstand variable weather.

One of the biggest advantages of galvanized mesh panels in fencing is their ability to balance security with visibility. Unlike solid fencing that blocks line of sight, mesh panels allow visibility while still preventing unauthorized access. This is especially useful in commercial zones where surveillance and open-air airflow are necessary. The uniform grid structure provided by galvanized welded wire mesh manufacturers ensures a strong, tamper-resistant barrier without compromising structural simplicity. In residential applications, these panels are equally popular for enclosing gardens, pet areas, and driveways.

Hebei Yisizhe Manufacture (Group) Limited offers a wide selection of fencing-grade galvanized mesh panels. Their products are designed for ease of installation, requiring minimal welding or complex hardware. Their zinc-coated wires are consistently welded using automated machines for uniformity, strength, and long-term reliability. Exported primarily to Europe, South America, and South Africa, their mesh panels meet diverse climate challenges and regulatory standards. The company’s commitment to "Quality as Base of Competition, Reputation as Base of Development" ensures consistent performance across all fencing applications.

Installation of galvanized welded wire mesh may seem straightforward, but doing it correctly ensures longevity, functionality, and safety. The first step is site preparation—clearing the installation path, leveling the ground, and setting up sturdy fence posts at regular intervals (typically 6 to 8 feet apart). These posts should be properly anchored in concrete to resist lateral pressure and environmental wear.

Next, roll out or lay the galvanised steel wire mesh sheet between posts, ensuring even tension. Use tension wires or bracing at the top and bottom to prevent sagging. The mesh should be attached using U-nails, hog rings, or specialized fencing staples, depending on the post material. For heavy-duty containment areas, like animal pens or industrial sites, double-layering or adding reinforcing bars may be necessary. Don’t forget to inspect the coating before and after installation. Damaged zinc layers can be retouched with cold galvanizing spray to maintain rust protection.

By sourcing from reputable galvanized welded wire mesh manufacturers such as Hebei Yisizhe Manufacture (Group) Limited, you ensure that the mesh you install is straight, structurally sound, and uniformly coated. Their advanced production processes and rigorous quality checks eliminate weak weld points and inconsistencies. For contractors or DIY users alike, these galvanized mesh panels provide excellent tensile strength and consistent spacing—making installation quicker and more effective. With long-term reliability and versatile applications, proper installation adds value to every meter of fencing.

Choosing the correct size and wire gauge of galvanized steel wire mesh is essential for effective agricultural use. Applications such as animal enclosures, chicken coops, crop protection, and storage fencing all require different configurations based on the type of livestock, potential predators, and expected weather conditions. The goal is to balance durability with functional design while ensuring animal safety and enclosure integrity.

For poultry enclosures or small livestock fencing, galvanized mesh panels with smaller grid openings (e.g., ½ inch to 1 inch) and medium-gauge wires (around 16–18 gauge) are ideal. These prevent small predators from entering while allowing sufficient airflow. For larger animals like goats or sheep, a heavier gauge (12–14) may be necessary to resist pressure from leaning or pushing. Where crop protection is the focus, lightweight panels can be used to build perimeter fencing around garden beds or orchards. The mesh can also be combined with frames to form cages or trellises for climbing plants.

Galvanized welded wire mesh manufacturers like Hebei Yisizhe provide multiple gauge options and grid sizes, allowing agricultural buyers to select custom specifications. The company’s strict quality control, zinc-rich coatings, and automation processes ensure all mesh sheets retain strength and corrosion resistance over long periods. Their customer-first policy also includes flexible post-payment terms for trusted partners. With a wide range of agricultural clients across continents, Hebei Yisizhe remains a reliable name in practical welded fence solutions.

When it comes to securing valuable goods, equipment, or restricted areas, galvanized mesh panels offer a reliable and cost-effective solution. Security cages constructed from galvanised steel wire mesh sheets are widely used in industrial warehouses, utility rooms, airport storage areas, and telecom enclosures. The inherent strength of these panels, combined with their corrosion resistance, makes them perfect for long-term use in both indoor and outdoor settings.

Unlike wooden partitions or drywall rooms, galvanized wire cages provide transparency and airflow—critical factors in environments where temperature control or visibility is essential. The mesh design allows surveillance cameras to monitor enclosed assets clearly while maintaining physical security. Moreover, using galvanized steel wire mesh instead of plain steel avoids issues with rust, which can compromise integrity and aesthetics. These panels are also modular, making them easy to customize according to room dimensions or changing layout requirements.

Hebei Yisizhe Manufacture (Group) Limited offers industrial-grade galvanized mesh panels specifically engineered for cage systems. These panels are welded at all intersections and galvanized post-weld for enhanced durability. As one of the established galvanized welded wire mesh manufacturers, the company’s panels come in customizable sizes and are shipped efficiently to their growing customer base across Europe, South America, and Africa. Whether you’re enclosing tools, chemicals, or electronics, their solutions provide unmatched value for long-term security.

Ravindra Kumar

Site Civil Engineer, India

James Otieno

Perimeter Security Contractor, South Africa

Omar Abdelrahman

City Infrastructure Supervisor, Egypt

Amy Okonkwo

Warehouse Operations Manager, Nigeria

Relaterade nyheter