溶接金網は高品質の低炭素鋼線で作られており、自動で精密かつ正確な機械設備のスポット溶接によって加工・成形されています。溶接金網の表面処理は亜鉛メッキで、従来の英国規格に従って製造されています。

溶接金網は最も経済的な材料として人気があります。

切断や圧力がかかっても緩むことなく、鉄製スクリーンの中で最も耐腐食性能が強く、最も多く使用されている鉄製スクリーンの一つです。

溶接金網は、工業、農業、建設、運輸、鉱業などの業界で広く使用されています。機械ガード、家畜フェンス、庭のフェンス、窓ガード、通路フェンス、家禽ケージ、卵バスケット、ホームオフィスの食品バスケット、ゴミ箱、装飾など。主に一般建築の外壁、コンクリートの注入、高層住宅などに使用されます。

断熱システムにおいて重要な構造的役割を果たします。施工時には、溶融亜鉛メッキ電気溶接グリッドポリスチレンボードを外壁の外型枠内に入れて注入します。外断熱ボードと壁は同時に存続し、型枠を取り除いた後、断熱ボードと壁は一体化します。

Welded Wire Mesh is excellent corrosion resistance and oxidation resistance. So it is one popular material in buiding construction, protection system, filtration, agriculture, and so on.

Finish:electro galvanized and hot-dipped galvanized

梱包: ロール状の防水紙。ご要望に応じてカスタム梱包も可能です。

Material and Process Analysis of Galvanized Welded Wire Mesh: Corrosion Resistance Performance

Galvanized welded wire mesh is a cornerstone material in construction, agriculture, and industrial applications, valued for its strength, versatility, and corrosion resistance. At YISIZHE, we specialize in manufacturing high-quality galvanized welded wire mesh by integrating premium materials and advanced processes, ensuring optimal performance even in harsh environments.

Core Materials: Foundation of Durability

1. Low-Carbon Steel Wire Substrate

Our galvanised iron wire mesh starts with low-carbon steel wire, chosen for its balanced ductility and tensile strength. This base material allows the mesh to withstand bending, cutting, or pressure without deforming—critical for applications like concrete reinforcement or livestock fencing.

2. Zinc Coating: The First Line of Defense

We offer two primary galvanization processes:

Electro-Galvanization: A thin zinc layer (10–30g/m²) applied via electrolysis, ideal for galvanized mesh panels used in dry, indoor, or mildly corrosive environments (e.g., garden fences, poultry cages).

Hot-Dip Galvanization: Immersing the mesh in molten zinc to form a thick, rugged layer (60–300g/m²), providing superior corrosion resistance for outdoor or harsh conditions (e.g., coastal projects, industrial partitions).

Welding Process: Structural Integrity Meets Precision

Our welded mesh galvanised wire panels are produced using automated resistance welding, fusing intersections at high temperatures to create solid, uniform joints. This process ensures:

No Loose Wires: weld points are stronger than the wire itself, preventing gaps that could compromise security or structural stability.

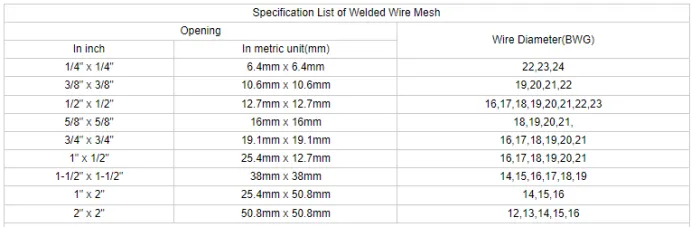

Consistent Mesh Sizes: From ¼"×¼" for fine filtration to 2"×2", our precision welding maintains exact specifications, critical for applications like concrete reinforcement or machine guards.

Corrosion Resistance: How Galvanization Works

The zinc coating on galvanised steel mesh panels acts as a sacrificial layer, oxidizing before the underlying steel to protect it from rust.

Hot-Dip Galvanized Mesh: Offers 10–15 years of outdoor durability (up to 20+ years in less corrosive areas), making it ideal for galvanized steel wire mesh used in infrastructure projects like highway barriers or building facades.

Electro-Galvanized Mesh: Suitable for short-term or indoor use, such as galvanised steel wire mesh sheets in storage racks or partition walls.

For extreme environments, we also provide PVC-coated galvanized mesh, adding a 0.2–0.4mm polymer layer to resist UV rays, moisture, and chemical exposure.

YISIZHE’s Manufacturing Excellence

As trusted galvanized welded wire mesh manufacturers, we prioritize:

Material Traceability: Sourcing steel from certified mills and testing zinc coating thickness to ensure compliance with ASTM/AISI standards.

Custom Solutions: Tailoring wire gauges (12–24 BWG), mesh sizes, and surface treatments to meet unique project needs—whether for a small-scale galvanized mesh garden fence or a large industrial galvanised steel wire mesh installation.

Cost-Effective Quality: Our automated production lines balance precision with affordability, delivering galvanized wire mesh for sale that offers long-term value without compromising on performance.

From agricultural fencing to high-rise construction, YISIZHE’s galvanized welded wire mesh combines robust materials, precise welding, and superior galvanization to deliver lasting corrosion resistance. Contact us today to explore our range or request a customized quote—engineered to exceed your expectations in durability and reliability.

Applications and Structural Roles of Galvanized Welded Wire Mesh in Construction Projects

Galvanized welded wire mesh is a pivotal material in modern construction, celebrated for its ability to enhance structural integrity, durability, and safety across diverse engineering projects. YISIZHE’s premium galvanized welded wire meshes are designed to meet the rigorous demands of construction environments, delivering both functional and protective benefits.

1. Concrete Reinforcement: Strengthening Foundation Structures

In concrete applications, galvanised iron wire mesh acts as a vital reinforcement layer, distributing tensile forces to prevent cracking and improve load-bearing capacity.

Foundation & Slab Construction: Placed within concrete slabs, driveways, or basement floors, its uniform grid structure (common mesh sizes: 1"×1" to 2"×2") enhances resistance to thermal expansion and mechanical stress.

Masonry Support: Used in brick or block walls, galvanised steel mesh panels stabilize mortar joints, reducing the risk of displacement in seismic or high-wind zones.

2. Exterior Insulation & Finish Systems (EIFS)

For energy-efficient buildings, galvanized mesh plays a critical role in exterior insulation systems:

Insulation Reinforcement: Installed over foam insulation boards, it provides a secure base for render or stucco finishes, ensuring long-term adhesion and impact resistance.

Weather Protection: The corrosion-resistant zinc coating of galvanized steel wire mesh shields against moisture and UV damage, extending the lifespan of exterior cladding in harsh climates.

3. Safety & Security in Building Envelopes

Window & Balcony Guards: Fine-mesh galvanised steel wire mesh sheets (e.g., ¼"×¼" to ½"×½") serve as fall-protection barriers while maintaining visibility, ideal for residential and commercial high-rises.

Fire Resistance Enhancement: When integrated into partition walls or ceilings, the mesh reinforces gypsum boards, delaying fire spread and improving structural integrity during emergencies.

4. Structural Stability in Renovation Projects

During retrofitting or seismic upgrades, welded mesh galvanised wire panels offer a cost-effective solution:

Crack Repair: Applied over existing walls with damaged plaster, the mesh redistributes stress to prevent further cracking.

Load Transfer: In reinforced concrete structures, it enhances the bond between old and new materials, ensuring seamless load distribution.

Why YISIZHE’s Galvanized Welded Wire Mesh Stands Out

Precision Engineering: Our galvanized welded wire mesh features resistance-welded joints that are stronger than the wire itself, ensuring no loose intersections in high-stress applications.

Customizable Specifications: Choose from wire gauges (12–24 BWG), mesh sizes, and galvanization types (electro or hot-dip) to match project requirements—whether for a small-scale renovation or a large commercial build.

Compliance with Standards: Meet or exceed ASTM A641 and ISO 1461 standards for zinc coating thickness, guaranteeing long-term performance in concrete, insulation, and safety systems.

From reinforcing foundations to safeguarding building exteriors, YISIZHE’s galvanized welded wire mesh is an indispensable asset in construction. Its unique combination of strength, corrosion resistance, and adaptability makes it the preferred choice for engineers and contractors worldwide. Contact us today to discuss how our galvanised steel wire meshes can elevate the safety and durability of your next project.

関連ニュース