jan . 31, 2025 01:34 Back to list

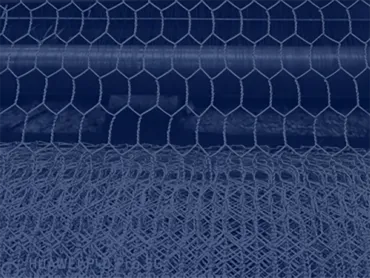

hexagonal wire netting

Hexagonal wire netting, more commonly known as chicken wire, is a versatile product used across a wide range of applications from agricultural to industrial settings. It’s renowned for its strength, durability, and flexibility, making it a staple in many sectors. Delving into the nuances of its application reveals how vital it is to a variety of industries and provides insight into selecting the right kind of netting for your specific needs.

Evaluating hexagonal wire netting for industrial purposes brings its adaptability into clearer focus. As industrial settings often require more robust solutions, the netting's tensile strength is enhanced through advanced manufacturing processes that include hot-dip galvanizing or the addition of a PVC coating. These coatings not only serve to prevent rust but also improve the structural integrity when used as reinforcements in concrete or stucco, where they deliver both stability and flexibility. For the layperson or small business looking to implement hexagonal wire netting, selecting the right gauge and mesh size is crucial. A tighter mesh size might be ideal for preventing small animal incursions, while a thicker gauge provides more strength and is suited for demanding structural applications. As such, understanding the specific requirements of your project can guide you to the perfect balance between mesh size, gauge, and coating, maximizing effectiveness and cost-efficiency. When considering a purchase, it is advisable to source materials from manufacturers with a long-standing reputation for quality and innovation. The assurance of expertise and authority in manufacturing ensures that the wire is compliant with international standards, thereby guaranteeing safety, reliability, and trustworthiness in every application. In essence, hexagonal wire netting is more than just a fencing solution—it is a multifaceted product that is indispensable across various domains. Whether used for agricultural protection, structural reinforcement, or environmental conservation, its role cannot be overstated. As our understanding of sustainable practices evolves, so too will the innovative uses of this essential material, perpetuating its relevance across industries worldwide.

Evaluating hexagonal wire netting for industrial purposes brings its adaptability into clearer focus. As industrial settings often require more robust solutions, the netting's tensile strength is enhanced through advanced manufacturing processes that include hot-dip galvanizing or the addition of a PVC coating. These coatings not only serve to prevent rust but also improve the structural integrity when used as reinforcements in concrete or stucco, where they deliver both stability and flexibility. For the layperson or small business looking to implement hexagonal wire netting, selecting the right gauge and mesh size is crucial. A tighter mesh size might be ideal for preventing small animal incursions, while a thicker gauge provides more strength and is suited for demanding structural applications. As such, understanding the specific requirements of your project can guide you to the perfect balance between mesh size, gauge, and coating, maximizing effectiveness and cost-efficiency. When considering a purchase, it is advisable to source materials from manufacturers with a long-standing reputation for quality and innovation. The assurance of expertise and authority in manufacturing ensures that the wire is compliant with international standards, thereby guaranteeing safety, reliability, and trustworthiness in every application. In essence, hexagonal wire netting is more than just a fencing solution—it is a multifaceted product that is indispensable across various domains. Whether used for agricultural protection, structural reinforcement, or environmental conservation, its role cannot be overstated. As our understanding of sustainable practices evolves, so too will the innovative uses of this essential material, perpetuating its relevance across industries worldwide.

Latest news

-

Reliable Nails for Every Construction Project

NewsJun.10,2025

-

Reliable Iron Nails for Every Project

NewsJun.10,2025

-

Razor Wire Solutions for Enhanced Security

NewsJun.10,2025

-

Hydraulic Hose Ferrule Fittings: Key to a Strong Hydraulic System

NewsJun.10,2025

-

Field Fencing: Secure Your Property with the Best Solutions

NewsJun.10,2025

-

Euro Fences: The Ultimate Choice for Security and Style

NewsJun.10,2025