Hydraulische slanghulzen

Commonly known as hydraulic fittings, hose fittings, hose inserts or fittings for short, are the elements that connect the hydraulic hose with the machine port where the hose has to be attached to, have two sides, the hose side consisting of a hollow hose barb stem which is inserted into the hose , and the threaded side which is connected to to the machine port.

Basically the fittings are referred to as two-piece fittings, that is, the fittings and the ferrule are swaged locking the hose in between the serrated dies of the ferrule and the stem, and one-piece fitting in which the ferrule and insert are crimped to a predetermined diameter

Although there is no unified International Standard but rather different standards, in practice coexist in the market, in our manufacturing program we cover most of the standards

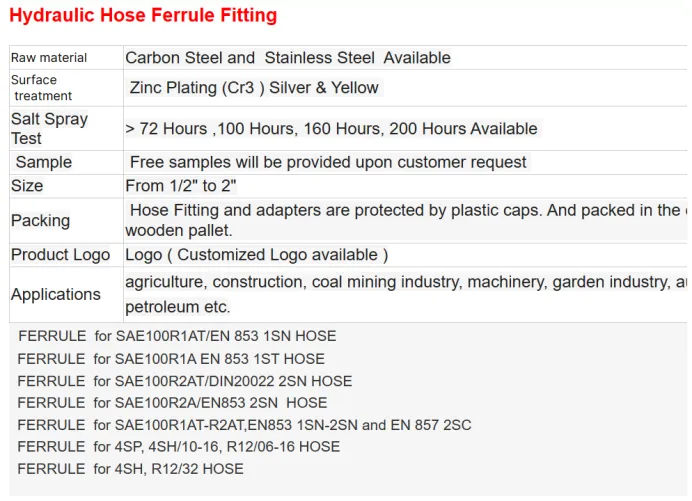

Hydraulic Hose Ferrule Fitting Specification

Basics of Hydraulic Hose Fittings

Hydraulic hose fittings are essential components in fluid systems, ensuring safe and efficient operation of hydraulic machinery and equipment. These fittings are used to connect hydraulic hoses to other components, such as pumps, valves, and cylinders, forming a leak-proof connection for high-pressure fluid transfer. The proper selection and installation of hydraulic hose fittings are crucial for the reliability and longevity of hydraulic systems.

One of the most commonly used types of hydraulic fittings is hydraulic hose ferrule fittings. These fittings are designed to securely attach hydraulic hoses to other system components. They consist of a metal sleeve (the ferrule) that is crimped around the hose to hold it firmly in place. The crimping process ensures a tight and durable seal that prevents leaks, even under extreme pressure conditions.

Importance of Hydraulic Hose Ferrule Fittings

Hydraulic hose ferrule fittings are known for their versatility and durability. They are commonly made from materials such as stainless steel or brass, which offer resistance to corrosion and wear. The ferrule itself is typically placed over the hose, and through crimping, it creates a strong bond that withstands the high pressures often encountered in hydraulic systems. This ability to withstand pressure is a primary reason why ferrule fittings are favored in industries such as construction, agriculture, and manufacturing, where hydraulic systems are subject to intense working conditions.

Choosing the Right Hydraulic Hose Ferrule Fittings

When selecting hydraulic hose ferrule fittings, it is essential to consider factors such as the hose size, the type of fluid being transported, and the operating pressure. The fitting's material must also be compatible with the environmental conditions to avoid damage and ensure a long service life. Additionally, the crimping process should be performed with precision to ensure a proper seal, which is vital to prevent leaks and system failures.

Various Types Of Hydraulic Hose Pipe Ferrule Fittings

Hydraulic hose pipe ferrule fittings are essential components in hydraulic systems, ensuring a secure and leak-free connection between the hose and other system parts. These fittings are designed to withstand high-pressure fluid transfer and offer durability under harsh conditions. There are several types of hydraulic hose pipe ferrule fittings, each designed for specific applications and performance requirements. Below are some common types:

1. Crimp Ferrule Fittings

Crimp ferrule fittings are one of the most widely used types in hydraulic systems. These fittings consist of a ferrule that is crimped around the hose using specialized equipment. The crimping process ensures a tight and secure bond between the hose and the fitting, which helps prevent leaks under high-pressure conditions. Crimp ferrule fittings are often used in industries such as construction, mining, and agriculture due to their reliability and strength.

2. Compression Ferrule Fittings

Compression ferrule fittings use a two-piece design, consisting of a ferrule and a compression nut. The ferrule is placed over the hose, and the compression nut is tightened to compress the ferrule, creating a secure seal. This type of fitting is often used in applications where a high level of sealing integrity is required. Compression ferrule fittings are suitable for both high and low-pressure hydraulic systems and are commonly found in automotive and industrial machinery.

3. Swaged Ferrule Fittings

Swaged ferrule fittings are used where a permanent, leak-proof connection is necessary. These fittings are made by placing the ferrule over the hose and then using a machine to permanently deform the ferrule to tightly grip the hose. Swaged ferrule fittings are typically employed in heavy-duty applications, such as in marine or offshore environments, where the fittings must withstand extreme pressures and vibrations.

4. Reusable Ferrule Fittings

Reusable ferrule fittings offer the advantage of being able to be disassembled and reused. These fittings feature a ferrule that can be re-crimped or re-tightened after maintenance or replacement of the hose. They are ideal for systems that require regular maintenance or adjustments, as they reduce the need for replacement fittings.

Benefits of Hydraulic Hose Ferrule Fittings

In the world of hydraulic systems, the choice of components can significantly affect performance, safety, and longevity. Among these components, hydraulic hose ferrule fittings play a crucial role in ensuring the secure connection and functionality of hydraulic hoses. YISIZHE hydraulic hose ferrule fittings stand out as an exemplary choice for professionals seeking quality and reliability in their hydraulic systems.

One of the primary benefits of YISIZHE hydraulic hose ferrule fittings is their superior durability. Engineered from high-quality materials, these fittings resist wear and tear caused by extreme pressure and varying temperatures. This durability ensures that the hydraulic hose remains intact, minimizing the risk of leaks and potential failures that could compromise system efficiency.

Moreover, YISIZHE hydraulic hose ferrule fittings are designed for optimal compatibility with a wide range of hydraulic hoses. This versatility allows users to utilize these fittings across multiple environments and applications without worrying about the risk of mismatched components. Whether in construction, agriculture, or industrial settings, these fittings provide a reliable solution.

Ease of installation is another noteworthy feature of YISIZHE hydraulic hose ferrule fittings. Their user-friendly design allows for quick and simple assembly, saving valuable time during maintenance or setup. This ease of use is particularly beneficial for professionals who need to ensure minimal downtime in their operations.

Additionally, YISIZHE hydraulic hose ferrule fittings maintain a secure and leak-proof seal, which is critical for safety in hydraulic systems. The precision engineering behind these fittings ensures a tight fit, preventing any fluid loss and ensuring that systems operate at peak performance.

In conclusion, the benefits of YISIZHE hydraulic hose ferrule fittings—including durability, compatibility, ease of installation, and leak-proof sealing—make them an exceptional choice for anyone involved in hydraulic systems. Investing in these high-quality fittings is an investment in the reliability and efficiency of your hydraulic operations.

Hydraulic Hose Ferrule Fittings: High-Pressure Sealing Solutions for Industrial Systems

In high-stakes industrial environments where leaks mean downtime and risk, hydraulic hose ferrule fittings are the critical link between flexible hose systems and reliable performance. YISIZHE, a trusted manufacturer, delivers precision-engineered hydraulic pipe ferrule fittings designed to withstand extreme pressures, corrosive conditions, and heavy-duty cycles—ensuring seamless operation in machinery, equipment, and pipelines.

1. Robust Materials for Uncompromising Durability

Our hydraulic hose ferrule fittings are crafted from high-grade carbon steel (for cost-effective strength) or stainless steel (for superior corrosion resistance), with surface treatments like Cr3 zinc plating offering 72+ hours of salt spray resistance. This makes them ideal for:

Construction machinery: Excavators and loaders exposed to mud, moisture, and vibration.

Agricultural equipment: Irrigation systems and tractors operating in humid, chemical-laden environments.

Marine applications: Offshore platforms and vessels where saltwater corrosion is a constant threat.

2. High-Pressure Sealing Technology

Engineered with precision hose crimp technology, our ferrules create permanent, leak-free connections:

Anti-slip serrations: Deep, uniform grooves grip hose interiors tightly, preventing slippage even under 6000 PSI pressure.

Seamless compression: Advanced crimping machinery ensures consistent wall thickness and dimensional accuracy, meeting international standards (SAE100R1AT, EN857 2SC, DIN 2353).

For reusable needs, our detachable ferrules allow easy hose replacement without tools, reducing maintenance downtime by 30% in industrial systems requiring frequent inspections.

3. Versatile Applications Across Industries

From small-bore flexible hose assemblies to large-diameter hydraulic pipelines, our fittings adapt to diverse requirements:

Mining equipment: Heavy-duty ferrules for slurry pumps and conveyor systems, resisting abrasion and high-temperature stress.

Industrial automation: Compact, corrosion-resistant ferrules for robotic arms and precision hydraulic controls.

Oil & gas: Stainless steel variants rated for harsh chemicals, ensuring safety in refineries and drilling rigs.

4. Why YISIZHE Leads in Hydraulic Ferrule Solutions

As a direct manufacturer, we combine technical expertise with customer-centric flexibility:

Full-size coverage: Sizes from 1/2" to 2" (6mm–51mm) for both imperial and metric systems, with custom diameters available for unique projects.

Quality assurance: Every ferrule undergoes pressure testing (1.5x working pressure) and dimensional checks to guarantee zero defects.

Global compatibility: Compliant with SAE, EN, and DIN standards, our fittings integrate seamlessly into international hydraulic systems.

Secure Your Systems with Precision Engineering

Don’t let connection failures disrupt operations. YISIZHE’s hydraulic hose ferrule fittings deliver the reliability needed for high-pressure, high-stakes environments. Whether you need permanent crimped seals for heavy machinery or reusable ferrules for maintenance-heavy setups, we have the solution. Contact us today to discuss your specifications and experience the difference of a leak-free, long-lasting hydraulic system.

Hydraulic Hose Ferrule Fittings: High-Pressure Sealing Solutions for Industrial Systems

In high-stakes industrial environments where leaks mean downtime and risk, hydraulic hose ferrule fittings are the critical link between flexible hose systems and reliable performance. YISIZHE, a trusted manufacturer, delivers precision-engineered hydraulic pipe ferrule fittings designed to withstand extreme pressures, corrosive conditions, and heavy-duty cycles—ensuring seamless operation in machinery, equipment, and pipelines.

1. Robust Materials for Uncompromising Durability

Our hydraulic hose ferrule fittings are crafted from high-grade carbon steel (for cost-effective strength) or stainless steel (for superior corrosion resistance), with surface treatments like Cr3 zinc plating offering 72+ hours of salt spray resistance. This makes them ideal for:

Construction machinery: Excavators and loaders exposed to mud, moisture, and vibration.

Agricultural equipment: Irrigation systems and tractors operating in humid, chemical-laden environments.

Marine applications: Offshore platforms and vessels where saltwater corrosion is a constant threat.

2. High-Pressure Sealing Technology

Engineered with precision hose crimp technology, our ferrules create permanent, leak-free connections:

Anti-slip serrations: Deep, uniform grooves grip hose interiors tightly, preventing slippage even under 6000 PSI pressure.

Seamless compression: Advanced crimping machinery ensures consistent wall thickness and dimensional accuracy, meeting international standards (SAE100R1AT, EN857 2SC, DIN 2353).

For reusable needs, our detachable ferrules allow easy hose replacement without tools, reducing maintenance downtime by 30% in industrial systems requiring frequent inspections.

3. Versatile Applications Across Industries

From small-bore flexible hose assemblies to large-diameter hydraulic pipelines, our fittings adapt to diverse requirements:

Mining equipment: Heavy-duty ferrules for slurry pumps and conveyor systems, resisting abrasion and high-temperature stress.

Industrial automation: Compact, corrosion-resistant ferrules for robotic arms and precision hydraulic controls.

Oil & gas: Stainless steel variants rated for harsh chemicals, ensuring safety in refineries and drilling rigs.

4. Why YISIZHE Leads in Hydraulic Ferrule Solutions

As a direct manufacturer, we combine technical expertise with customer-centric flexibility:

Full-size coverage: Sizes from 1/2" to 2" (6mm–51mm) for both imperial and metric systems, with custom diameters available for unique projects.

Quality assurance: Every ferrule undergoes pressure testing (1.5x working pressure) and dimensional checks to guarantee zero defects.

Global compatibility: Compliant with SAE, EN, and DIN standards, our fittings integrate seamlessly into international hydraulic systems.

Secure Your Systems with Precision Engineering

Don’t let connection failures disrupt operations. YISIZHE’s hydraulic hose ferrule fittings deliver the reliability needed for high-pressure, high-stakes environments. Whether you need permanent crimped seals for heavy machinery or reusable ferrules for maintenance-heavy setups, we have the solution. Contact us today to discuss your specifications and experience the difference of a leak-free, long-lasting hydraulic system.

Gerelateerd nieuws