11月 . 06, 2024 03:25 Back to list

Welded Wire Mesh Providers for Various Industrial Applications and Custom Solutions

The Role of Welded Mesh Suppliers in Modern Construction

In today's construction and manufacturing landscape, the use of welded mesh has become increasingly vital due to its versatility, strength, and efficiency. Welded mesh, a grid-like structure made from intersecting metal wires that are welded at their joints, serves a multitude of purposes across various industries, from building materials and fencing solutions to agricultural applications and industrial flooring. This article explores the role of welded mesh suppliers, the advantages of welded mesh products, as well as the factors to consider when selecting a reliable supplier.

Understanding Welded Mesh

Welded mesh is typically made from high-quality steel or wire, providing exceptional durability and strength. The mesh is manufactured by arranging the wires in a uniform grid pattern, which are then fused together at their intersections using electrical resistance welding. This process results in a robust structure that can bear significant loads and resist deformation.

Welded mesh is available in different sizes, wire diameters, and spacing, allowing for customization to meet specific project requirements. Its applications are vast and include concrete reinforcement, safety barriers, livestock containment, and decorative solutions, among others. Its ability to provide structural support while being relatively lightweight makes it an indispensable material in construction.

The Importance of Welded Mesh Suppliers

Welded mesh suppliers play a crucial role in the availability and distribution of welded mesh products. They not only manufacture these materials but also ensure that they are of high quality and compliant with industry standards. A reliable supplier acts as a bridge between manufacturers and end-users, providing essential products that meet project-specific needs.

1. Quality Assurance One of the primary roles of welded mesh suppliers is to maintain high standards of quality. This includes sourcing raw materials that meet industry specifications and employing rigorous testing methods to assess the strength and durability of their products. Suppliers that adhere to quality assurance protocols help mitigate the risk of structural failures in construction projects.

welded mesh suppliers

2. Customization and Variety Different projects require different specifications, which is where the flexibility of suppliers comes into play. Many suppliers offer a range of products, including various mesh sizes, shapes, and coatings (such as galvanized or PVC-coated options) to meet the diverse needs of their clients. This customization is essential for projects that require specific mechanical properties or aesthetic considerations.

3. Timely Delivery and Logistics In the fast-paced construction industry, time is often of the essence. Efficient suppliers ensure that materials are delivered on time, preventing costly project delays. They also manage logistics and inventory, allowing contractors to focus on their core activities rather than worrying about material shortages.

4. Technical Support and Expertise Many reputable welded mesh suppliers provide not only products but also technical support. Their expertise can be invaluable when it comes to selecting the right type of mesh for a specific application, understanding installation techniques, or navigating compliance with local building codes and regulations.

Choosing the Right Supplier

Selecting the right welded mesh supplier is crucial for the success of your project. Here are some factors to consider

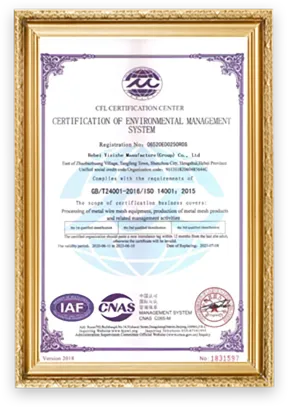

- Reputation and Experience Look for suppliers with a proven track record in the industry. Reviews and referrals from previous clients can provide insight into their reliability and product quality. - Product Range Ensure that the supplier offers a wide variety of products that can meet your specific needs. This flexibility often indicates a supplier's capacity to handle diverse projects. - Certifications Check if the supplier holds relevant certifications that demonstrate compliance with industry standards. This can be a strong indicator of product quality. - Customer Service Choose suppliers that offer excellent customer service. A responsive team can assist you in troubleshooting issues and provide guidance throughout the purchasing process.

Conclusion

Welded mesh suppliers are essential partners in the construction and manufacturing industries. Their ability to provide high-quality, durable, and customizable products can significantly impact the success of various projects. By choosing a reputable supplier, businesses can ensure they have access to the materials they need while benefiting from expert guidance and dependable service. As the demand for welded mesh continues to grow, the role of these suppliers will only become more critical in delivering innovative solutions for modern construction challenges.

-

Weather Resistance Properties of Quality Roofing Nails

NewsAug.01,2025

-

How Galvanised Iron Mesh Resists Corrosion in Harsh Environments

NewsAug.01,2025

-

Creative Landscaping Uses for PVC Coated Wire Mesh Panels

NewsAug.01,2025

-

Common Wire Nail Dimensions and Their Specific Applications

NewsAug.01,2025

-

Choosing the Right Welded Wire Sheets for Agricultural Fencing

NewsAug.01,2025

-

Anti - Climbing Features of Razor Wire Barriers

NewsAug.01,2025