1月 . 30, 2025 01:06 Back to list

hydraulic pipe ferrule fittings

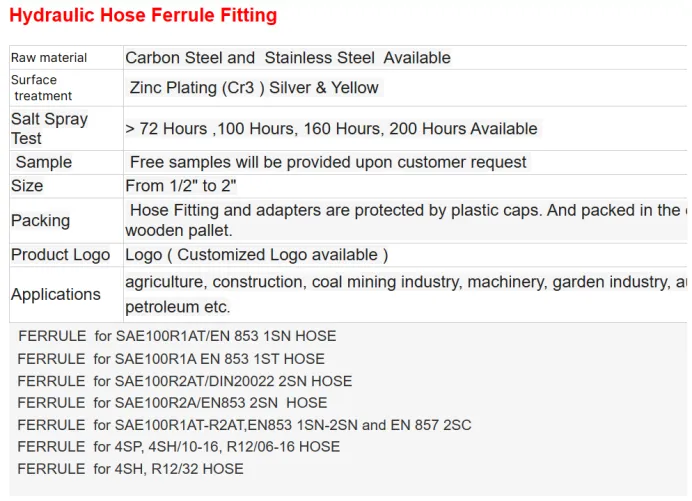

Hydraulic pipe ferrule fittings are essential components used in various industries for their reliability and efficiency in connecting and sealing hydraulic systems. Understanding their significance and proper application is crucial for optimizing system performance and ensuring safety. Here, we'll explore these fittings from the perspective of experience, expertise, authoritativeness, and trustworthiness, providing an in-depth look at what makes them indispensable in the field of fluid power technology.

Trustworthiness in hydraulic ferrule fittings stems from rigorous quality control and testing procedures adhered to by reputable manufacturers. These procedures typically include pressure testing, spectrometric analysis of materials, and fatigue testing, all designed to validate the fitting's performance under operational stresses. Certifications such as ISO 9001 for quality management and other industry-specific endorsements further build trust, signifying that the product meets international standards of excellence. Furthermore, feedback from experienced engineers and technicians who have worked extensively with hydraulic systems reinforces the reliability of quality ferrule fittings. Case studies and real-world applications provide evidence of their effectiveness in varied contexts, from industrial machinery to aerospace applications, underscoring their adaptability and indispensability. In conclusion, hydraulic pipe ferrule fittings are not just mere components; they are pivotal to the safety and efficiency of hydraulic systems. Choosing fittings from authoritative and reputable sources with proven quality and adhering to expert installation guidelines can significantly enhance system performance. Companies and engineers who prioritize these aspects can expect reduced downtime, cost savings, and robust system performance, making hydraulic ferrule fittings an investment in reliability and efficiency.

Trustworthiness in hydraulic ferrule fittings stems from rigorous quality control and testing procedures adhered to by reputable manufacturers. These procedures typically include pressure testing, spectrometric analysis of materials, and fatigue testing, all designed to validate the fitting's performance under operational stresses. Certifications such as ISO 9001 for quality management and other industry-specific endorsements further build trust, signifying that the product meets international standards of excellence. Furthermore, feedback from experienced engineers and technicians who have worked extensively with hydraulic systems reinforces the reliability of quality ferrule fittings. Case studies and real-world applications provide evidence of their effectiveness in varied contexts, from industrial machinery to aerospace applications, underscoring their adaptability and indispensability. In conclusion, hydraulic pipe ferrule fittings are not just mere components; they are pivotal to the safety and efficiency of hydraulic systems. Choosing fittings from authoritative and reputable sources with proven quality and adhering to expert installation guidelines can significantly enhance system performance. Companies and engineers who prioritize these aspects can expect reduced downtime, cost savings, and robust system performance, making hydraulic ferrule fittings an investment in reliability and efficiency.

Next:

Latest news

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025