tammi . 29, 2025 02:29 Back to list

hydraulic hose end fittings

Hydraulic hose end fittings are the often-overlooked heroes in the world of machinery and equipment. These components serve a vital function, sealing and connecting hydraulic hoses to ensure system efficiency and safety. Understanding and selecting the right hydraulic hose end fitting is not just a matter of convenience; it can significantly impact the performance and longevity of your hydraulic systems.

Trustworthiness in the context of hydraulic hose end fittings can be measured by the reliability and safety records of the products. Consistent product testing, backed by strong quality management systems such as ISO 9001, can assure users of the dependability of the fittings. Furthermore, providers who offer transparent warranties and service plans enhance trust by committing to the long-term performance of their products. When installing hydraulic hose end fittings, ensuring proper mating and torque specifications is paramount. Incorrect installation can lead to leakage, hose blow-off, and potential system failures. Utilizing a torque wrench and following manufacturer guidelines ensures that fittings are neither over-tightened nor too loose, both of which can compromise the integrity of the hydraulic system. Real-world experience plays a crucial role in understanding the practical nuances of using hydraulic hose end fittings. For instance, seasoned professionals recognize the importance of regularly inspecting fittings for signs of wear, corrosion, or damage, which can preemptively identify potential issues before they lead to costly failures. Field experience also underscores the value of using sealants or thread tapes appropriately, as over-reliance on these materials can sometimes mask underlying problems with fitting compatibility or condition. In conclusion, selecting and maintaining the right hydraulic hose end fittings requires a blend of technical knowledge, compliance with industry standards, and practical experience. By leveraging expertise from credible sources, understanding the material and type of fittings best suited for the application, and following rigorous maintenance protocols, one can greatly enhance the performance, safety, and lifespan of hydraulic systems. For businesses and professionals operating in hydraulics, a strategic focus on fittings not only optimizes equipment efficiency but also builds a robust foundation for operational success.

Trustworthiness in the context of hydraulic hose end fittings can be measured by the reliability and safety records of the products. Consistent product testing, backed by strong quality management systems such as ISO 9001, can assure users of the dependability of the fittings. Furthermore, providers who offer transparent warranties and service plans enhance trust by committing to the long-term performance of their products. When installing hydraulic hose end fittings, ensuring proper mating and torque specifications is paramount. Incorrect installation can lead to leakage, hose blow-off, and potential system failures. Utilizing a torque wrench and following manufacturer guidelines ensures that fittings are neither over-tightened nor too loose, both of which can compromise the integrity of the hydraulic system. Real-world experience plays a crucial role in understanding the practical nuances of using hydraulic hose end fittings. For instance, seasoned professionals recognize the importance of regularly inspecting fittings for signs of wear, corrosion, or damage, which can preemptively identify potential issues before they lead to costly failures. Field experience also underscores the value of using sealants or thread tapes appropriately, as over-reliance on these materials can sometimes mask underlying problems with fitting compatibility or condition. In conclusion, selecting and maintaining the right hydraulic hose end fittings requires a blend of technical knowledge, compliance with industry standards, and practical experience. By leveraging expertise from credible sources, understanding the material and type of fittings best suited for the application, and following rigorous maintenance protocols, one can greatly enhance the performance, safety, and lifespan of hydraulic systems. For businesses and professionals operating in hydraulics, a strategic focus on fittings not only optimizes equipment efficiency but also builds a robust foundation for operational success.

Latest news

-

Welded Mesh Panels: The Ultimate Solution for Versatility and Durability

NewsMay.23,2025

-

Top Wire Mesh Solutions for Your Needs

NewsMay.23,2025

-

The Versatility and Strength of Welded Wire Mesh: A Comprehensive Guide

NewsMay.23,2025

-

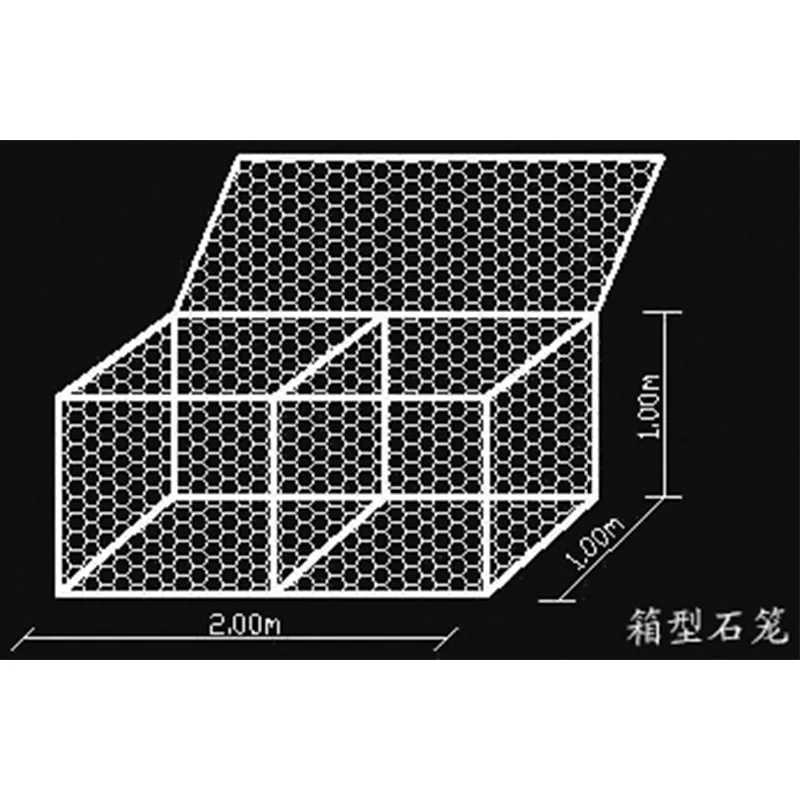

The Power of Gabion Boxes: Practical and Durable

NewsMay.23,2025

-

PVC Coated Welded Wire Mesh: The Durable, Versatile Solution You Need

NewsMay.23,2025

-

Pre-Cut Wire: The Perfect Solution for Your Needs

NewsMay.23,2025