Ιαν . 14, 2025 09:43 Back to list

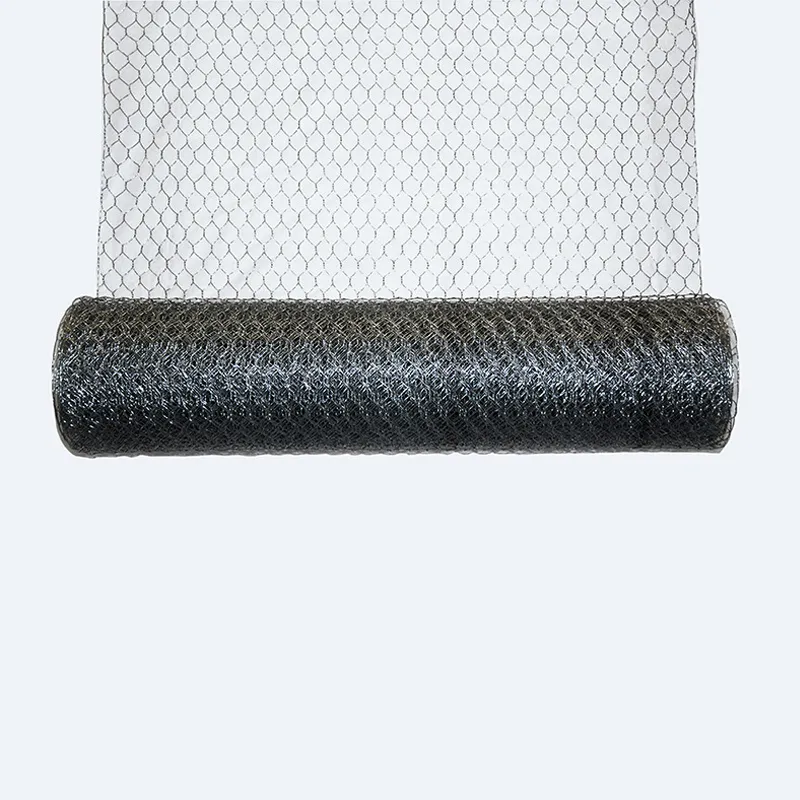

mesh for plastering

Choosing the right mesh for plastering can significantly influence the durability, appearance, and longevity of a surface. As industry professionals with years of expertise, it's important to delve into the nuances of materials and applications to guide optimal selections.

Practical experience reveals that environmental conditions play a significant role in mesh performance. For example, in high-humidity regions, selecting a mesh resistant to moisture damage is essential. In colder climates, flexible mesh that accommodates freeze-thaw cycles without degrading ensures longevity and reduces maintenance frequencies. Adapting mesh choice to environmental conditions reflects both expertise and forethought, essential qualities in the application of plastering materials. Validation and trustworthiness in mesh selection also arise from adhering to safety standards and industry certifications. Premium meshes often undergo rigorous testing to meet or exceed regulatory requirements, offering assurances of their performance capabilities. Professionals can rely on these certifications to inform their decisions, thus aligning with industry best practices and fostering trust in client relationships. Expertise in mesh for plastering also extends into product innovation and awareness of new materials entering the market. Emerging technologies in composite materials may offer enhanced characteristics such as improved fire resistance or eco-friendliness, appealing to sustainability-conscious projects. Staying abreast of these advances signifies professional credibility and positions experts as leaders within the field. In conclusion, selecting the appropriate mesh for plastering involves a complex interplay of material properties, environmental considerations, and technical proficiency. By leveraging expert knowledge and adhering to authoritative standards, professionals can achieve outstanding results, reinforcing their reputation for quality in the competitive construction industry.

Practical experience reveals that environmental conditions play a significant role in mesh performance. For example, in high-humidity regions, selecting a mesh resistant to moisture damage is essential. In colder climates, flexible mesh that accommodates freeze-thaw cycles without degrading ensures longevity and reduces maintenance frequencies. Adapting mesh choice to environmental conditions reflects both expertise and forethought, essential qualities in the application of plastering materials. Validation and trustworthiness in mesh selection also arise from adhering to safety standards and industry certifications. Premium meshes often undergo rigorous testing to meet or exceed regulatory requirements, offering assurances of their performance capabilities. Professionals can rely on these certifications to inform their decisions, thus aligning with industry best practices and fostering trust in client relationships. Expertise in mesh for plastering also extends into product innovation and awareness of new materials entering the market. Emerging technologies in composite materials may offer enhanced characteristics such as improved fire resistance or eco-friendliness, appealing to sustainability-conscious projects. Staying abreast of these advances signifies professional credibility and positions experts as leaders within the field. In conclusion, selecting the appropriate mesh for plastering involves a complex interplay of material properties, environmental considerations, and technical proficiency. By leveraging expert knowledge and adhering to authoritative standards, professionals can achieve outstanding results, reinforcing their reputation for quality in the competitive construction industry.

Next:

Latest news

-

The Power of Iron Wire: A Versatile Solution for Multiple Applications

NewsJun.19,2025

-

Reliable Hydraulic Fittings for Optimal Performance

NewsJun.19,2025

-

Quality Roofing Nails for Every Project

NewsJun.19,2025

-

Hexagonal Wire Mesh: Versatile and Durable Solutions for Every Project

NewsJun.19,2025

-

Enhancing Security with Barbed Wire Solutions

NewsJun.19,2025

-

Binding Wire: The Essential Material for a Variety of Applications

NewsJun.19,2025