Feb . 10, 2025 10:17 Back to list

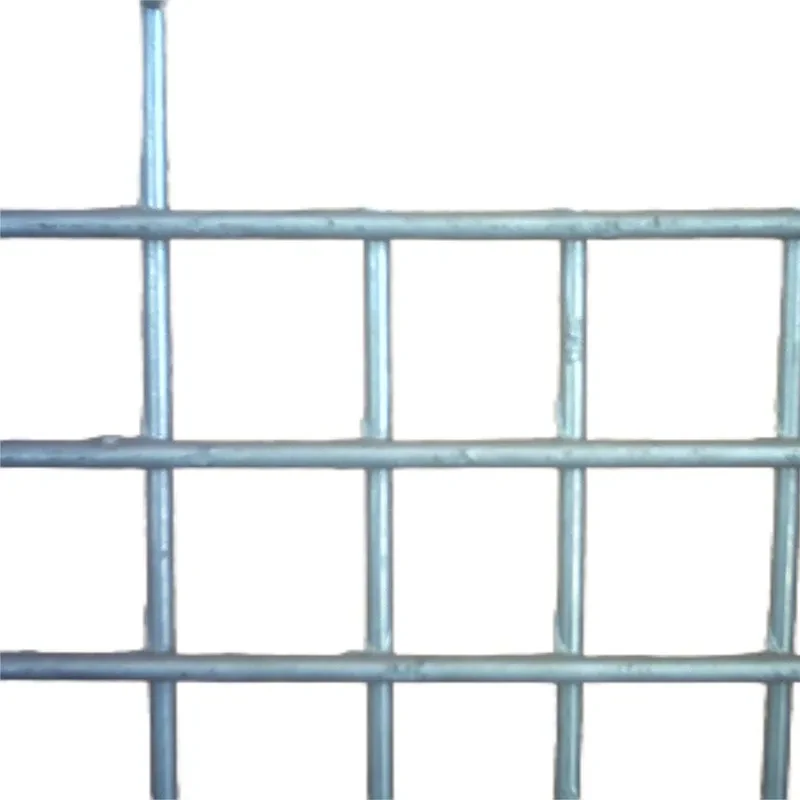

galvanized mesh

Choosing the right material for fencing and construction purposes often boils down to durability, cost-effectiveness, and adaptability to various environmental and functional demands. Among these, galvanized mesh has emerged as a standout option, offering a reliable solution for both domestic and industrial applications. This article delves into why galvanized mesh is not just a smart choice but often the best one, drawing from real-world experiences, professional assessments, and its robust standing in the market.

Experts in material sciences and architecture have long heralded galvanized mesh for its adaptability. Its capacity to mold into different shapes without losing structural integrity makes it applicable in a variety of designs. Whether used in constructing gabions for erosion control or as fencing in zoos and wildlife parks, it accommodates creative and structural demands with ease. On a sustainability note, galvanized mesh is also an environmentally responsible choice. Steel is 100% recyclable and the galvanization process, when conducted efficiently, minimizes waste and environmental impact. Opting for galvanized mesh not only secures your project durability but also aligns with sustainable construction practices. A critical consideration for any procurement process is cost-effectiveness. The initial investment in galvanized mesh may be slightly higher than untreated steel or other metals, but the long-term benefits outweigh these initial costs. The decreased need for frequent replacements and repairs offsets the upfront expense, providing excellent return on investment over the years. In summary, the appeal of galvanized mesh lies in its ability to combine strength, adaptability, and cost-effectiveness into a single, versatile material. Its widespread use across multiple industries is a testament to its capabilities and reliability. Whether for securing a simple backyard or underpinning the integrity of a multi-story building, galvanized mesh stands out as a choice grounded in expertise, experience, authority, and trust. It does not just meet current needs but often anticipates future demands, securing its place as a pillar in both modern and traditional construction and design.

Experts in material sciences and architecture have long heralded galvanized mesh for its adaptability. Its capacity to mold into different shapes without losing structural integrity makes it applicable in a variety of designs. Whether used in constructing gabions for erosion control or as fencing in zoos and wildlife parks, it accommodates creative and structural demands with ease. On a sustainability note, galvanized mesh is also an environmentally responsible choice. Steel is 100% recyclable and the galvanization process, when conducted efficiently, minimizes waste and environmental impact. Opting for galvanized mesh not only secures your project durability but also aligns with sustainable construction practices. A critical consideration for any procurement process is cost-effectiveness. The initial investment in galvanized mesh may be slightly higher than untreated steel or other metals, but the long-term benefits outweigh these initial costs. The decreased need for frequent replacements and repairs offsets the upfront expense, providing excellent return on investment over the years. In summary, the appeal of galvanized mesh lies in its ability to combine strength, adaptability, and cost-effectiveness into a single, versatile material. Its widespread use across multiple industries is a testament to its capabilities and reliability. Whether for securing a simple backyard or underpinning the integrity of a multi-story building, galvanized mesh stands out as a choice grounded in expertise, experience, authority, and trust. It does not just meet current needs but often anticipates future demands, securing its place as a pillar in both modern and traditional construction and design.

Latest news

-

Weather Resistance Properties of Quality Roofing Nails

NewsAug.01,2025

-

How Galvanised Iron Mesh Resists Corrosion in Harsh Environments

NewsAug.01,2025

-

Creative Landscaping Uses for PVC Coated Wire Mesh Panels

NewsAug.01,2025

-

Common Wire Nail Dimensions and Their Specific Applications

NewsAug.01,2025

-

Choosing the Right Welded Wire Sheets for Agricultural Fencing

NewsAug.01,2025

-

Anti - Climbing Features of Razor Wire Barriers

NewsAug.01,2025