Jan . 10, 2025 13:20 Back to list

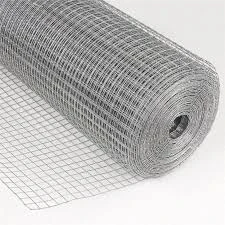

coated chicken wire

Coated chicken wire has revolutionized various industries by offering a blend of durability, adaptability, and safety. Whether you are an agricultural enthusiast or a DIY project aficionado, the use of coated chicken wire extends beyond conventional applications, offering a robust solution for diverse needs.

Coated chicken wire's adaptability extends to structural reinforcements. In construction projects, it can be used for plaster support and concrete reinforcement, where its coated finish helps to prevent corrosion, thereby reinforcing longevity and performance. This protective attribute ensures that structures maintain their integrity under various conditions, enhancing trust in its reliability among construction professionals. Furthermore, the environmental impact of coated chicken wire is a factor worth considering. Many manufacturers are now prioritizing eco-friendly production methods, using materials that are recyclable and minimizing the ecological footprint. This aligns with the increasing demand for sustainable options in all sectors, from agriculture to construction. Expertise in selecting the right type of coated chicken wire can make a significant difference. Evaluating factors like wire gauge, coating thickness, and intended application are crucial for optimizing its performance. Consulting with professionals or suppliers who have authority and experience in the field can provide valuable insights and recommendations tailored to specific needs. In conclusion, coated chicken wire stands out as a product that effectively merges utility with innovation. Its extensive range of applications, coupled with enhanced safety and environmental features, makes it a preferred choice across various domains. By leveraging its strengths, users can ensure that they are investing in a versatile, reliable, and sustainable material designed to withstand the test of time.

Coated chicken wire's adaptability extends to structural reinforcements. In construction projects, it can be used for plaster support and concrete reinforcement, where its coated finish helps to prevent corrosion, thereby reinforcing longevity and performance. This protective attribute ensures that structures maintain their integrity under various conditions, enhancing trust in its reliability among construction professionals. Furthermore, the environmental impact of coated chicken wire is a factor worth considering. Many manufacturers are now prioritizing eco-friendly production methods, using materials that are recyclable and minimizing the ecological footprint. This aligns with the increasing demand for sustainable options in all sectors, from agriculture to construction. Expertise in selecting the right type of coated chicken wire can make a significant difference. Evaluating factors like wire gauge, coating thickness, and intended application are crucial for optimizing its performance. Consulting with professionals or suppliers who have authority and experience in the field can provide valuable insights and recommendations tailored to specific needs. In conclusion, coated chicken wire stands out as a product that effectively merges utility with innovation. Its extensive range of applications, coupled with enhanced safety and environmental features, makes it a preferred choice across various domains. By leveraging its strengths, users can ensure that they are investing in a versatile, reliable, and sustainable material designed to withstand the test of time.

Next:

Latest news

-

Reliable Nails for Every Construction Project

NewsJun.10,2025

-

Reliable Iron Nails for Every Project

NewsJun.10,2025

-

Razor Wire Solutions for Enhanced Security

NewsJun.10,2025

-

Hydraulic Hose Ferrule Fittings: Key to a Strong Hydraulic System

NewsJun.10,2025

-

Field Fencing: Secure Your Property with the Best Solutions

NewsJun.10,2025

-

Euro Fences: The Ultimate Choice for Security and Style

NewsJun.10,2025