Jan . 11, 2025 12:01 Back to list

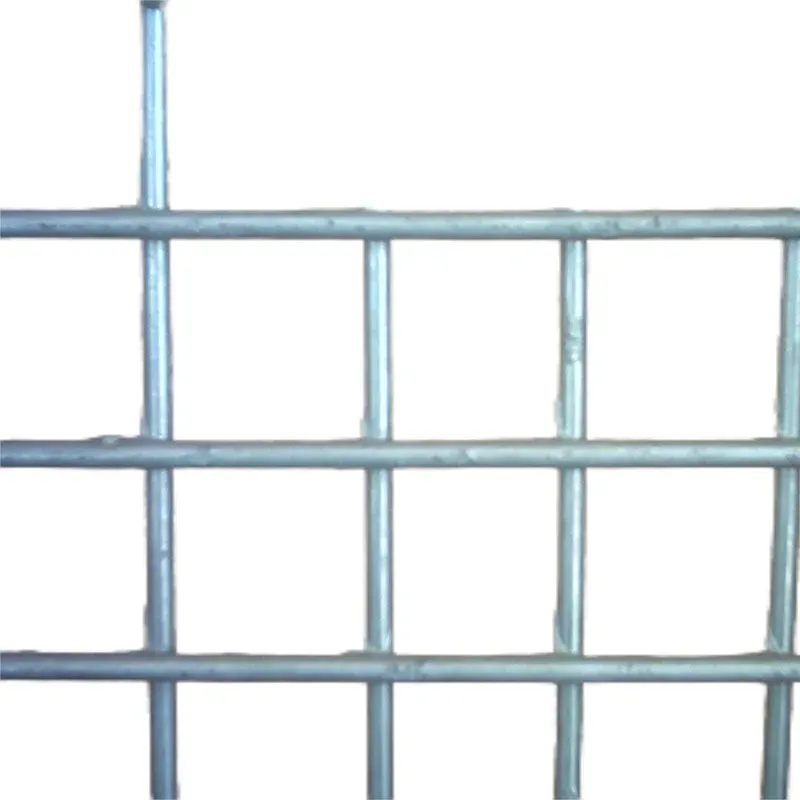

chicken coop wire mesh

Choosing the right chicken coop wire mesh is a pivotal decision for anyone interested in poultry farming or keeping chickens as pets. As an expert in the field, I understand that the safety and comfort of your birds directly depend on the quality of the mesh you select. This article provides a comprehensive guide that relies on real-world experiences and professional insights, addressing the necessity for a suitable wire mesh that encompasses the E-A-T principles Experience, Expertise, Authority, and Trustworthiness.

Consumer trust is paramount when selecting materials, as poor-quality wire mesh can lead to potential losses in poultry stocks. It's wise to invest in trusted brands that adhere to international safety and quality standards. Using testimonials and reviews from established farmers can guide you towards reputable suppliers and brands. Aesthetics may not be the primary concern, but the choice of wire mesh should align with the overall appearance of your setup. Some meshes come with colored powder coatings that not only elevate the visual appeal but also offer additional layers of protection, making your coop both secure and pleasing to look at. Lastly, regular maintenance of your chicken coop wire mesh can extend its lifespan. Inspecting for signs of wear and rust, especially after extreme weather, ensures that the mesh continues to deliver on its promise of protection. A maintenance schedule grounded in real-world farming activities fosters reliability, demonstrating to potential buyers or users that the product is trustworthy. In conclusion, selecting the right chicken coop wire mesh is an involved process that should prioritize safety, durability, and practicality based on expert recommendations and real-life experiences. By focusing on quality and proper installation, you can build a secure environment that reflects authority and stands the test of time in your poultry endeavors.

Consumer trust is paramount when selecting materials, as poor-quality wire mesh can lead to potential losses in poultry stocks. It's wise to invest in trusted brands that adhere to international safety and quality standards. Using testimonials and reviews from established farmers can guide you towards reputable suppliers and brands. Aesthetics may not be the primary concern, but the choice of wire mesh should align with the overall appearance of your setup. Some meshes come with colored powder coatings that not only elevate the visual appeal but also offer additional layers of protection, making your coop both secure and pleasing to look at. Lastly, regular maintenance of your chicken coop wire mesh can extend its lifespan. Inspecting for signs of wear and rust, especially after extreme weather, ensures that the mesh continues to deliver on its promise of protection. A maintenance schedule grounded in real-world farming activities fosters reliability, demonstrating to potential buyers or users that the product is trustworthy. In conclusion, selecting the right chicken coop wire mesh is an involved process that should prioritize safety, durability, and practicality based on expert recommendations and real-life experiences. By focusing on quality and proper installation, you can build a secure environment that reflects authority and stands the test of time in your poultry endeavors.

Next:

Latest news

-

Weather Resistance Properties of Quality Roofing Nails

NewsAug.01,2025

-

How Galvanised Iron Mesh Resists Corrosion in Harsh Environments

NewsAug.01,2025

-

Creative Landscaping Uses for PVC Coated Wire Mesh Panels

NewsAug.01,2025

-

Common Wire Nail Dimensions and Their Specific Applications

NewsAug.01,2025

-

Choosing the Right Welded Wire Sheets for Agricultural Fencing

NewsAug.01,2025

-

Anti - Climbing Features of Razor Wire Barriers

NewsAug.01,2025