Дек . 12, 2024 11:21 Back to list

welded wire sheets

Understanding Welded Wire Sheets Versatility in Construction and Design

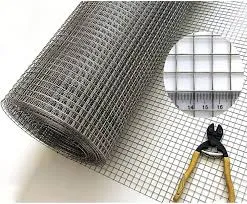

Welded wire sheets, commonly known as welded wire mesh or welded wire fabric, are an essential component in the construction and manufacturing industries. Comprising a series of intersecting wires welded at their junctions, these sheets offer exceptional strength, durability, and versatility. They can be utilized in a variety of applications, from reinforcing concrete structures to forming cages for agricultural purposes. This article delves into the composition, benefits, and diverse uses of welded wire sheets in today's world.

Composition and Manufacturing Process

Welded wire sheets are typically made from high-quality steel wires, although stainless steel and other metals can also be utilized for specific applications. The manufacturing process begins with the drawing of wire rods into finer diameters, followed by the cutting and arranging of wires into a specified grid pattern. This grid is then subjected to high-temperature welding, creating a robust bond at each intersection. The resulting sheets can vary in wire diameter, mesh size, and dimensions, allowing customization to meet specific project needs.

Benefits of Welded Wire Sheets

1. Strength and Durability One of the primary advantages of welded wire sheets is their inherent strength. The welded joints provide a stable structure, making them less prone to cracking or bending under load. This characteristic is crucial in construction settings where reliability is paramount.

2. Cost-Effectiveness Welded wire sheets are often more economical compared to traditional reinforcement methods such as rebar. They are easy to handle and require less labor for installation, resulting in reduced overall costs for construction projects.

3. Versatility These sheets can be used in a myriad of applications. Whether reinforcing concrete in slabs, walls, or columns, or creating cages for animals in agriculture, the flexibility in size and shape makes welded wire sheets a valuable resource.

4. Ease of Installation The uniformity of welded wire sheets allows for straightforward installation. They can be cut to size and shaped as needed, making them convenient for various project requirements. Moreover, the lightweight nature of these sheets facilitates easy transport and handling.

5. Resistance to Environmental Factors Welded wire sheets, especially those made from galvanized or stainless steel, exhibit excellent resistance to rust and corrosion. This quality extends their longevity and reliability in outdoor applications or environments with moisture exposure.

welded wire sheets

Applications of Welded Wire Sheets

Welded wire sheets find their application across numerous industries, highlighting their versatility

1. Construction In the realm of construction, these sheets are predominantly used for concrete reinforcement. They enhance the structural integrity of slabs, beams, and walls, providing crucial support.

2. Agriculture Welded wire sheets are employed to create enclosures for livestock, prevent the escape of animals, and protect crops from pests. They serve as sturdy fencing solutions that withstand weather conditions.

3. Landscaping In landscaping, welded wire sheets can be used as retaining walls, trellises, or supports for plants. Their customizable nature allows for aesthetic integration into garden designs.

4. Industrial Uses These sheets are also common in industrial settings, where they can be used as platforms, safety barriers, or storage racks. Their durability ensures they can withstand heavy loads and harsh conditions.

5. Home Improvement Homeowners utilize welded wire sheets in various DIY projects, such as building outdoor furniture, garden trellises, or security enhancements for properties.

Conclusion

Welded wire sheets represent an essential innovation in construction and a wide range of practical applications. Their unique blend of strength, affordability, and versatility makes them a go-to choice for professionals across multiple industries. As technology advances and new materials become available, the use of welded wire sheets is expected to evolve further, contributing to safer, more efficient structures and creative designs. Whether for large-scale construction or individual projects, the role of welded wire sheets continues to be indispensable.

-

Weather Resistance Properties of Quality Roofing Nails

NewsAug.01,2025

-

How Galvanised Iron Mesh Resists Corrosion in Harsh Environments

NewsAug.01,2025

-

Creative Landscaping Uses for PVC Coated Wire Mesh Panels

NewsAug.01,2025

-

Common Wire Nail Dimensions and Their Specific Applications

NewsAug.01,2025

-

Choosing the Right Welded Wire Sheets for Agricultural Fencing

NewsAug.01,2025

-

Anti - Climbing Features of Razor Wire Barriers

NewsAug.01,2025