Дек . 18, 2024 05:02 Back to list

Top Manufacturers of Razor Wire Fences for Enhanced Security Solutions

The Role of Razor Wire Fence Manufacturers in Modern Security Solutions

In an age where security is at the forefront of both personal and commercial interests, the role of razor wire fence manufacturers has become increasingly vital. As threats evolve and security challenges mount, the demand for robust fencing solutions that offer both physical barriers and psychological deterrents has surged. This article delves into the significance of razor wire fencing, the production processes employed by manufacturers, and the various applications in which these formidable barriers are utilized.

Understanding Razor Wire Fencing

Razor wire fencing, characterized by sharp blades or barbs integrated into wire strands, is often associated with high-security applications. It is designed to deter unauthorized entry, making it a popular choice for military installations, prisons, warehouses, and critical infrastructure. The engineering behind razor wire involves a combination of strength and precision; the materials used must not only withstand environmental elements but also provide an imposing visual deterrent.

Razor wire is available in several forms, including concertina wire and flat-wrap wire. Concertina wire is coiled and can expand significantly, creating a barrier that is difficult to traverse. Flat-wrap wire, on the other hand, is designed for straight lines and can be affixed to existing fences for added security. Manufacturers continuously innovate to improve the effectiveness and versatility of these products, adapting to diverse needs across different industries.

The Manufacturing Process

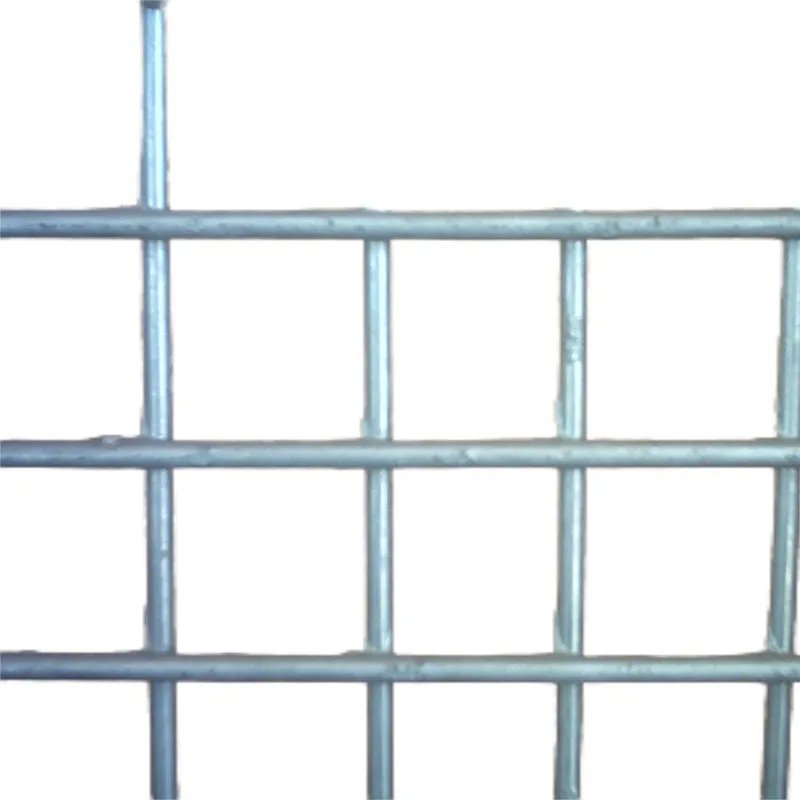

The manufacturing of razor wire involves several stages, each requiring meticulous attention to detail to ensure quality and effectiveness. The process typically begins with the selection of appropriate materials, commonly galvanized steel or stainless steel. These materials are chosen for their resistance to corrosion, ensuring longevity and durability in various environmental conditions.

After material selection, the manufacturing process involves shaping the wire, adding barbs or blades, and coiling it into the desired form—either concertina or flat-wrap. Advanced machinery is employed to ensure uniformity and precision during production, which is crucial for maintaining the integrity of the fence. Manufacturers also adhere to strict safety standards to ensure that the finished product is not only effective but also compliant with relevant regulations.

razor wire fence manufacturers

Testing is another critical component of the manufacturing process. Razor wire must be subjected to rigorous testing to assess its tensile strength and ability to withstand tampering. This feedback loop allows manufacturers to make necessary adjustments to improve product performance and safety.

Applications Across Sectors

Razor wire fencing is utilized in a wide array of applications, showcasing its versatility and effectiveness. One of the most prominent sectors employing razor wire is the security industry. High-security facilities, such as prisons and military bases, rely on these barriers to prevent escape or unauthorized entry. Additionally, critical infrastructure, including power plants and telecommunications facilities, often use razor wire to protect against vandalism and terrorism.

Beyond the traditional uses, razor wire fencing is gaining traction in commercial enterprises. Retail stores, warehouses, and distribution centers are increasingly adopting these security measures to safeguard against theft and vandalism. The psychological deterrent of razor wire can often prevent crime before it occurs, making it a cost-effective investment for businesses.

Furthermore, residential applications have emerged, particularly in high-crime areas. Homeowners seeking enhanced security measures may choose to install razor wire fencing as part of a broader security system. However, it is crucial for individuals to consider local laws and regulations governing the use of razor wire in residential settings to avoid legal complications.

Conclusion

Razor wire fence manufacturers play a pivotal role in addressing modern security challenges. Through innovative manufacturing processes and a commitment to quality, these manufacturers provide effective solutions that are essential for safeguarding property and assets. As threats evolve, so too will the designs and applications of razor wire fencing, ensuring that communities—whether commercial or residential—can rely on effective barriers for peace of mind. In a world increasingly focused on security, the contributions of razor wire fence manufacturers will be instrumental in shaping the future of protective measures.

-

Weather Resistance Properties of Quality Roofing Nails

NewsAug.01,2025

-

How Galvanised Iron Mesh Resists Corrosion in Harsh Environments

NewsAug.01,2025

-

Creative Landscaping Uses for PVC Coated Wire Mesh Panels

NewsAug.01,2025

-

Common Wire Nail Dimensions and Their Specific Applications

NewsAug.01,2025

-

Choosing the Right Welded Wire Sheets for Agricultural Fencing

NewsAug.01,2025

-

Anti - Climbing Features of Razor Wire Barriers

NewsAug.01,2025