Dez . 05, 2024 03:35 Back to list

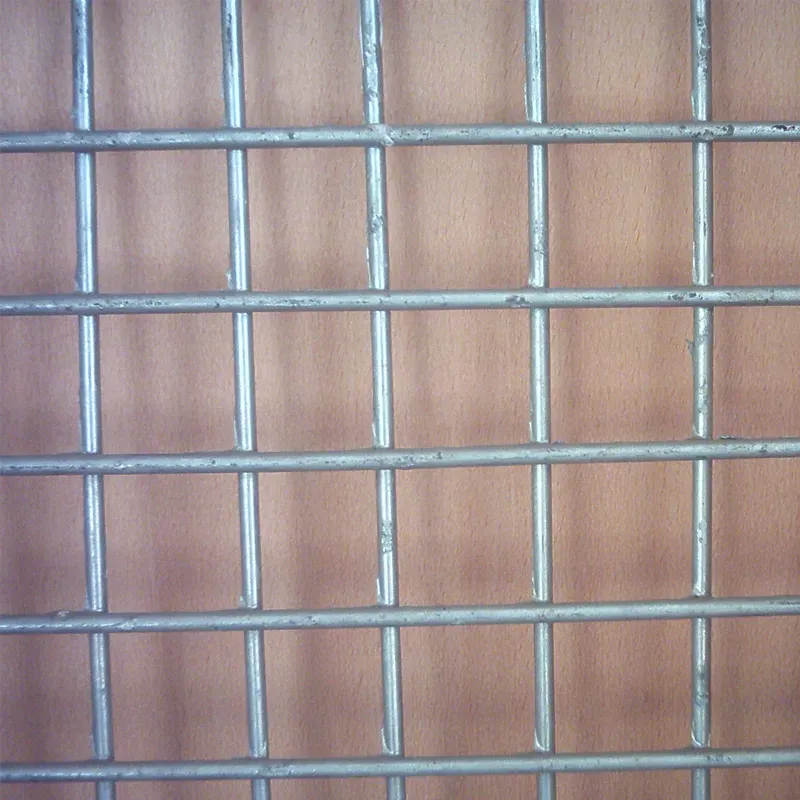

Quality Diamond Mesh Production for Enhanced Durability and Versatility in Various Applications

The Rise of Diamond Mesh Manufacturers A Comprehensive Overview

In today’s industrial landscape, the demand for durable and versatile materials continues to grow. Among these materials, diamond mesh has emerged as a favored choice for a variety of applications ranging from construction to agriculture. This article explores the significance of diamond mesh manufacturers, the production processes they employ, and the benefits of using diamond mesh products.

Understanding Diamond Mesh

Diamond mesh refers to a type of wire mesh that features a diamond-shaped pattern. This design not only enhances the aesthetic appeal of the product but also provides optimal strength and flexibility. Typically made from materials such as stainless steel, aluminum, or galvanized wire, diamond mesh is renowned for its durability and resistance to corrosion, making it suitable for both indoor and outdoor applications.

The Role of Diamond Mesh Manufacturers

Diamond mesh manufacturers play a crucial role in the supply chain of industrial materials. These manufacturers are responsible for producing high-quality mesh sheets, rolls, and custom configurations to meet the diverse needs of their clients. Their operations involve several stages, including material sourcing, weaving, quality control, and distribution.

1. Material Sourcing The choice of raw materials significantly impacts the performance of diamond mesh. Manufacturers often select materials that meet specific standards for strength and weather resistance. This is especially important for outdoor applications, where exposure to various environmental conditions can lead to deterioration.

2. Weaving Process The weaving techniques employed by manufacturers vary, impacting the final product's characteristics. Different weaving patterns can enhance the mesh's flexibility or hardness, making it suitable for specific uses such as fencing, reinforcement, or as a barrier in agricultural settings.

3. Quality Control To maintain competitiveness, manufacturers implement stringent quality control measures. This involves testing the tensile strength, flexibility, and durability of the mesh under various conditions. Adhering to industry standards helps ensure that the products meet customer expectations and safety requirements.

diamond mesh manufacturer

4. Distribution After production, manufacturers must efficiently distribute their products to reach end-users. This often entails collaborating with distributors, wholesalers, and retailers, as well as offering direct sales options for large-scale clients in industries such as construction, mining, and landscaping.

Benefits of Using Diamond Mesh

The popularity of diamond mesh can be attributed to its myriad benefits

- Versatility Diamond mesh is used in various applications, including fencing for livestock, reinforcement in construction, and safety barriers in mining operations. Its adaptability makes it a go-to material for engineers and contractors.

- Durability The inherent strength of diamond mesh materials ensures longevity, reducing the need for frequent replacements. This is particularly advantageous in industries that require robust solutions for challenging environments.

- Cost-Effectiveness Despite its many advantages, diamond mesh remains relatively affordable compared to other materials. Manufacturers often leverage economies of scale to offer competitive pricing, making diamond mesh an attractive option for budget-conscious projects.

- Aesthetic Appeal The diamond pattern adds an element of design that can enhance the visual appeal of structures. This is particularly beneficial in landscaping and architectural applications where aesthetics are a key consideration.

Conclusion

As the demand for durable and versatile materials continues to rise, the role of diamond mesh manufacturers becomes increasingly vital. With their commitment to quality and innovation, these manufacturers are well-positioned to meet the growing needs of various industries. By understanding the production processes and benefits of diamond mesh, businesses can make informed decisions that enhance their operations and contribute to projects' overall success. As we look ahead, the importance of reliable suppliers in the diamond mesh market will undoubtedly grow, reinforcing the structural integrity and aesthetic value of modern construction and beyond.

-

Weather Resistance Properties of Quality Roofing Nails

NewsAug.01,2025

-

How Galvanised Iron Mesh Resists Corrosion in Harsh Environments

NewsAug.01,2025

-

Creative Landscaping Uses for PVC Coated Wire Mesh Panels

NewsAug.01,2025

-

Common Wire Nail Dimensions and Their Specific Applications

NewsAug.01,2025

-

Choosing the Right Welded Wire Sheets for Agricultural Fencing

NewsAug.01,2025

-

Anti - Climbing Features of Razor Wire Barriers

NewsAug.01,2025