Set . 01, 2024 07:05 Back to list

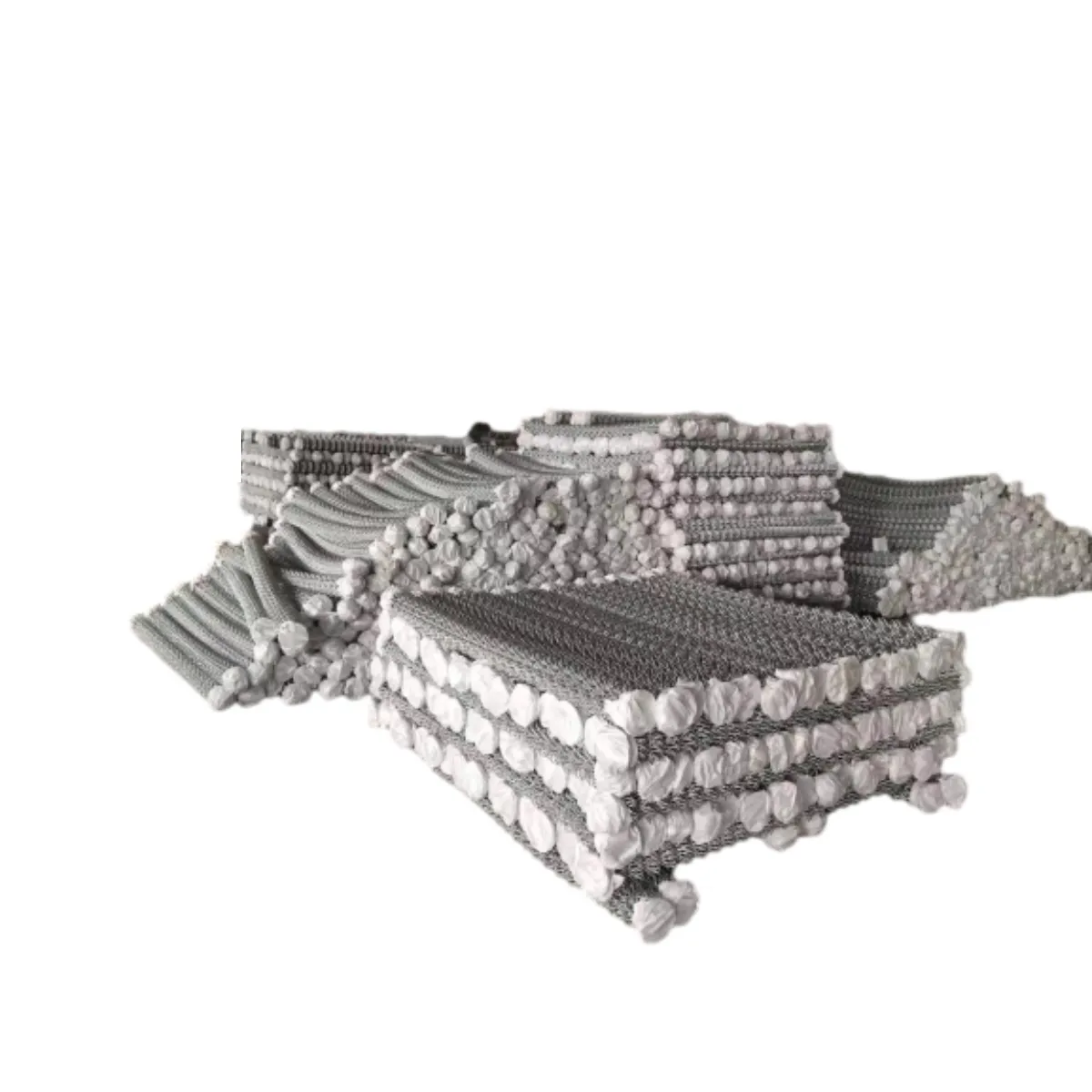

diamond mesh factory

The Diamond Mesh Factory Crafting Quality and Durability

In the modern industrial landscape, the need for high-quality materials is paramount. One such essential product is diamond mesh, widely used in various applications ranging from construction to agriculture. The diamond mesh factory plays a crucial role in producing this versatile material, known for its strength, durability, and aesthetic appeal.

A diamond mesh is characterized by its distinct diamond-shaped openings, which provide enhanced structural integrity compared to traditional mesh designs. This unique pattern allows for better airflow, making it a popular choice for fencing, safety barriers, and even decorative purposes. The manufacturing process of diamond mesh involves several key steps that ensure the final product meets the highest standards of quality.

The journey begins with selecting raw materials, typically high-quality steel or wire. These materials are chosen for their strength and resistance to corrosion, ensuring that the finished mesh can withstand the elements and any mechanical stress. The wire is then drawn and treated to achieve the desired thickness and tensile strength.

diamond mesh factory

Once the materials are prepared, the fabrication process commences. This involves cutting the wire to specific lengths and then weaving or welding it into the diamond mesh pattern. Advanced machinery in a diamond mesh factory enhances precision and efficiency, enabling the production of large quantities while maintaining consistent quality.

Quality control is a critical aspect of the manufacturing process. Each batch of diamond mesh undergoes rigorous testing to ensure it adheres to industry standards. This includes assessing the tensile strength, corrosion resistance, and overall durability. Factories often employ automated systems to monitor production and conduct these tests, minimizing human error and improving reliability.

Furthermore, the diamond mesh factory recognizes the importance of sustainability. Many factories are implementing eco-friendly practices, such as recycling scrap material and using energy-efficient machinery. This commitment to the environment not only reduces waste but also appeals to increasingly eco-conscious consumers.

In conclusion, a diamond mesh factory serves as a pivotal link in the supply chain of modern materials. By combining advanced technology, skilled craftsmanship, and a commitment to quality, these factories produce diamond mesh that meets the diverse needs of industries worldwide. Whether used for security, safety, or aesthetics, diamond mesh continues to demonstrate its value across various sectors, solidifying its place as a fundamental material in today's economy.

-

Weather Resistance Properties of Quality Roofing Nails

NewsAug.01,2025

-

How Galvanised Iron Mesh Resists Corrosion in Harsh Environments

NewsAug.01,2025

-

Creative Landscaping Uses for PVC Coated Wire Mesh Panels

NewsAug.01,2025

-

Common Wire Nail Dimensions and Their Specific Applications

NewsAug.01,2025

-

Choosing the Right Welded Wire Sheets for Agricultural Fencing

NewsAug.01,2025

-

Anti - Climbing Features of Razor Wire Barriers

NewsAug.01,2025