okt . 15, 2024 18:05 Back to list

Top Suppliers of PVC Coated Wire Mesh for Various Applications and Industries

The Role of PVC Coated Wire Mesh Manufacturers in Modern Applications

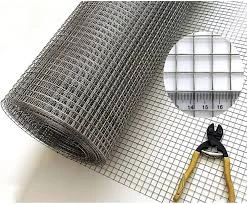

PVC coated wire mesh is an essential material used across various industries due to its durability, versatility, and aesthetic appeal. Manufacturers of PVC coated wire mesh play a crucial role in providing high-quality products that cater to the needs of diverse sectors, including construction, agriculture, and landscaping. This article delves into the significance of PVC coated wire mesh, the manufacturing process, and the benefits it offers.

Understanding PVC Coated Wire Mesh

PVC coated wire mesh is created by coating a base metal wire, typically made of steel or galvanized wire, with a layer of polyvinyl chloride (PVC). This coating not only enhances the wire's resistance to corrosion and rust but also improves its overall appearance. The resulting mesh is available in various gauges, colors, and sizes, making it suitable for numerous applications.

Applications of PVC Coated Wire Mesh

1. Construction and Safety Fencing In construction, PVC coated wire mesh is extensively used for safety fencing around building sites. Its sharp edges are typically minimized, making it safer for workers and passersby. Additionally, the bright colors of PVC coatings make it highly visible, reducing the chances of accidents.

2. Agricultural Uses Farmers often employ PVC coated wire mesh for livestock enclosures and garden fencing. The coating provides durability against harsh weather conditions while preventing rust, which is vital when dealing with fertilizers and other chemical substances common in agriculture.

3. Landscaping Landscape architects and gardeners use PVC coated wire mesh for decorative fences, trellises, and plant support structures. The variety of colors available allows for creative landscaping designs that enhance aesthetic appeal without sacrificing functionality.

4. Industrial Applications In industrial settings, PVC coated wire mesh is used for partitioning and storage. Its ability to withstand harsh chemicals and physical damage makes it a preferred choice for warehouses and factories.

The Manufacturing Process

pvc coated wire mesh manufacturers

Manufacturers follow a meticulous process to produce high-quality PVC coated wire mesh. The initial step involves selecting the appropriate base wire, which is then cleaned and prepped for coating. Afterward, the wire undergoes a coating process, where it is submerged in molten PVC or passed through a PVC powder that adheres to the wire when heated. Once coated, the wire is cooled and cut to desired specifications.

Quality control is a significant aspect of the manufacturing process. This includes testing the coating thickness, adherence, and overall strength of the mesh to ensure it meets industry standards. Manufacturers also focus on environmental concerns, ensuring that their production methods comply with regulations to minimize waste and emissions.

Benefits of PVC Coated Wire Mesh

1. Durability The PVC coating significantly enhances the lifespan of the wire mesh, making it resistant to rust, corrosion, and UV damage. This ensures that the mesh remains functional even in extreme weather conditions.

2. Aesthetic Appeal The variety of colors available for PVC coatings allows for customization, enabling users to choose options that fit their design preferences and project requirements.

3. Low Maintenance Unlike uncoated metal wire, which requires frequent maintenance to prevent rust, PVC coated wire mesh is virtually maintenance-free, saving time and costs in the long run.

4. Safety The smooth, rounded edges of PVC coated wire mesh reduce the risk of injuries, making it safer for various applications, especially in public spaces and homes.

Conclusion

In conclusion, PVC coated wire mesh manufacturers play a pivotal role in supplying durable, attractive, and versatile materials for a wide range of applications. Their commitment to quality and innovation ensures that industries can rely on these products to meet their needs. As demand continues to grow in sectors like construction, agriculture, and landscaping, the importance of these manufacturers is likely to increase, paving the way for advancements in material technology and design.

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025