dec . 15, 2024 14:06 Back to list

poultry wire mesh factory

Poultry Wire Mesh Factory Ensuring Quality and Safety in Poultry Farming

The poultry industry is a pivotal sector in global agriculture, providing essential food sources and economic support to millions of families. From egg production to meat processing, the demand for poultry products continues to grow, leading to advancements in farming techniques and equipment. Among the critical components that facilitate modern poultry farming is poultry wire mesh, manufactured in specialized factories dedicated to producing high-quality mesh for various poultry applications.

The Importance of Poultry Wire Mesh

Poultry wire mesh serves multiple functions in the farming environment. Primarily, it ensures the safety and security of poultry by providing a protective barrier against predators. It also facilitates proper ventilation and allows for the free movement of air, which is vital in maintaining a healthy environment for the birds. Additionally, poultry wire mesh is used in nesting boxes, feeding troughs, and even as flooring to keep the poultry comfortable and safe.

Features of Quality Poultry Wire Mesh

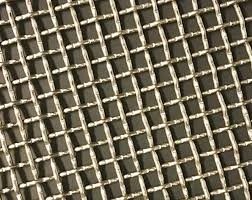

When it comes to poultry wire mesh, quality is paramount. The ideal mesh should be made from durable materials, often galvanized steel or stainless steel, to resist corrosion and wear over time. Strong, well-spaced wires are crucial to ensure that the mesh can withstand the daily rigors of farming life, including elements such as rain, dust, and droppings without compromising its integrity.

Moreover, the mesh should be designed with small openings to prevent chicks or smaller birds from escaping while allowing ample airflow and sunlight. This design consideration helps maintain a comfortable and healthy environment, reducing stress among the flock and promoting optimal growth and productivity.

Manufacturing Process of Poultry Wire Mesh

poultry wire mesh factory

The manufacturing of poultry wire mesh typically begins with selecting high-quality raw materials. Manufacturers usually opt for steel wires that have undergone galvanization, a process that coats the metal with zinc to enhance its resistance to rust and corrosion. After the wire is treated, it is cut to the required length and fed into a mesh weaving machine.

The weaving process involves interlacing the wires to form a grid pattern, which can vary in size depending on the specific requirements of the end user. Some wire mesh may be produced in rolls for flexible applications, while others may be made into panels for straightforward installation. Once the weaving is complete, the mesh is inspected thoroughly for quality assurance, ensuring that it meets industry standards before being packaged and shipped to customers worldwide.

Customization for Specific Needs

One of the key advantages of poultry wire mesh factories is their ability to provide customized solutions. Farmers often have unique requirements based on their farming practices, the type of poultry they raise, and environmental factors specific to their location. Leading manufacturers will collaborate closely with farmers to understand their needs and provide tailored mesh products that ensure maximum efficiency and safety in their operations.

Sustainability and Eco-Friendliness

In recent years, there has been a growing emphasis on sustainability within the poultry farming industry. Many poultry wire mesh factories are adopting eco-friendly practices, such as using recyclable materials and reducing waste during the manufacturing process. By prioritizing sustainable methods, these factories are not only helping to protect the environment but also appealing to consumers who are increasingly concerned about the ecological impact of agricultural practices.

Conclusion

Poultry wire mesh is a fundamental element in the success of poultry farming. With the continuous evolution of farming techniques, the role of dedicated poultry wire mesh factories becomes even more critical. By producing high-quality, durable, and customizable products, these factories play a vital role in enhancing the efficiency and safety of poultry operations, ensuring that farmers can meet the growing demand for poultry products sustainably and responsibly. As the industry continues to advance, the relationship between poultry farming and wire mesh production will undoubtedly remain strong—connecting the farmer's dedication to animal welfare with the essential tools that help them succeed.

-

Weather Resistance Properties of Quality Roofing Nails

NewsAug.01,2025

-

How Galvanised Iron Mesh Resists Corrosion in Harsh Environments

NewsAug.01,2025

-

Creative Landscaping Uses for PVC Coated Wire Mesh Panels

NewsAug.01,2025

-

Common Wire Nail Dimensions and Their Specific Applications

NewsAug.01,2025

-

Choosing the Right Welded Wire Sheets for Agricultural Fencing

NewsAug.01,2025

-

Anti - Climbing Features of Razor Wire Barriers

NewsAug.01,2025