Dis . 05, 2024 15:00 Back to list

hydraulic hose end fittings

Understanding Hydraulic Hose End Fittings

In the realm of fluid power transmission, hydraulic hoses play a pivotal role in connecting various components of hydraulic systems. The integrity and performance of these systems heavily depend on the quality and design of hydraulic hose end fittings. These fittings are crucial components that secure hoses to hydraulic apparatus, ensuring the seamless flow of fluids under pressure. This article delves into the various types, applications, and important considerations regarding hydraulic hose end fittings.

Types of Hydraulic Hose End Fittings

Hydraulic hose end fittings come in several varieties, each designed for specific applications and requirements. The most common types include

1. Bite Type Fittings These fittings bite into the hose when crimped, providing a strong mechanical hold. They are widely used in high-pressure applications due to their robustness.

2. Swage Fittings Utilizing a process called swaging, these fittings create a permanent connection between the hose and fitting. They are ideal for high-pressure environments and offer excellent resistance to leakage.

3. Reusable Fittings As the name suggests, these fittings can be used multiple times. They allow for easy assembly and disassembly, making them suitable for applications where maintenance is frequent.

4. Push-On Fittings These fittings are designed for easy installation without the need for crimping. They are often used in low-pressure applications and are user-friendly.

5. Flared Fittings Common in various hydraulic systems, flared fittings use a conical or tapered end for sealing. This design provides a reliable connection and is often employed in high-temperature environments.

Applications of Hydraulic Hose End Fittings

Hydraulic hose end fittings are utilized across numerous industries due to their versatility. Common applications include

- Construction Equipment Hydraulic systems in excavators, bulldozers, and loaders rely on reliable hose end fittings to ensure safe and efficient operations.

hydraulic hose end fittings

- Agriculture Tractors and other agricultural machinery use hydraulic hoses fitted with the appropriate end fittings to control equipment such as plows and harvesters

.- Manufacturing Hydraulic systems in manufacturing processes—such as presses and automated machinery—depend on robust hose fittings to facilitate the movement and control of materials.

- Automotive In automotive repair and maintenance, hydraulic hose end fittings are essential for systems like braking and power steering.

- Marine Applications From steering mechanisms to winches, hydraulic fittings are paramount in ensuring reliable operation in harsh marine environments.

Considerations When Choosing Hydraulic Hose End Fittings

Selecting the appropriate hydraulic hose end fittings requires careful consideration of various factors to ensure compatibility and performance

1. Pressure Rating It is essential to choose fittings that can withstand the required working pressures without risk of failure.

2. Size and Compatibility The fitting's size must match the hose diameter, and its design should be compatible with the hydraulic system’s overall configuration.

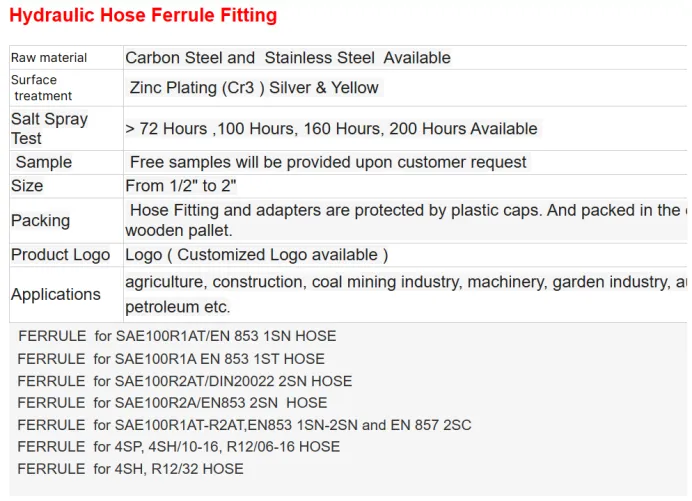

3. Material Selection Depending on the environment and the types of fluids being transported, materials such as stainless steel, brass, or carbon steel may be preferable for longevity and resistance to corrosion.

4. Temperature Resistance Consider the operating temperature range, as excessive heat can degrade both the hose and fittings, leading to potential failures.

5. Installation Method Whether crimped, swaged, or reusable, the method of installation can significantly affect the performance and longevity of the connection.

In conclusion, hydraulic hose end fittings are vital components in hydraulic systems, with their selection influencing the overall reliability and efficiency of various applications. By understanding the types available, their applications, and the factors to consider when choosing them, engineers and maintenance professionals can ensure optimal performance and safety in hydraulic operations. Whether in construction, agriculture, or manufacturing, the right fittings will enhance operational efficiency and maintain the integrity of hydraulic systems.

-

The Power of Iron Wire: A Versatile Solution for Multiple Applications

NewsJun.19,2025

-

Reliable Hydraulic Fittings for Optimal Performance

NewsJun.19,2025

-

Quality Roofing Nails for Every Project

NewsJun.19,2025

-

Hexagonal Wire Mesh: Versatile and Durable Solutions for Every Project

NewsJun.19,2025

-

Enhancing Security with Barbed Wire Solutions

NewsJun.19,2025

-

Binding Wire: The Essential Material for a Variety of Applications

NewsJun.19,2025