Dis . 19, 2024 06:43 Back to list

Cut Wire Manufacturing Solutions for Efficient Production and Quality Assurance

The Importance of Cut Wire Factories in Modern Manufacturing

In today’s fast-paced manufacturing ecosystem, the demand for precision and quality is paramount. One of the unsung heroes in this realm is the cut wire factory, a facility that specializes in the production of cut wire products used across various industries. From construction to electronics, cut wire is essential for numerous applications, and understanding its production process, applications, and impact on the industry is crucial.

What is Cut Wire?

Cut wire refers to metal wire that has been cut into specific lengths to meet the requirements of diverse manufacturing processes. The materials used in cut wire production can vary widely and include stainless steel, carbon steel, copper, aluminum, and more. The wires can be produced in different gauges, lengths, and coatings to cater to the precise needs of various applications.

Production Process

The manufacturing process in cut wire factories involves several key steps. Initially, large spools or coils of wire are drawn and created from raw materials. These wires are then fed into cutting machines designed to slice them into predetermined lengths. Quality control measures are a critical aspect of this process, ensuring that each piece meets the specified criteria.

After cutting, the wires often undergo additional processes such as bending, straightening, or even surface treatments, such as galvanizing or coating. These enhancements help improve the wire's durability and resistance to environmental factors. Once the production process is complete, the finished cut wires are packaged and shipped to various industries, ready to be integrated into a range of products.

Applications of Cut Wire

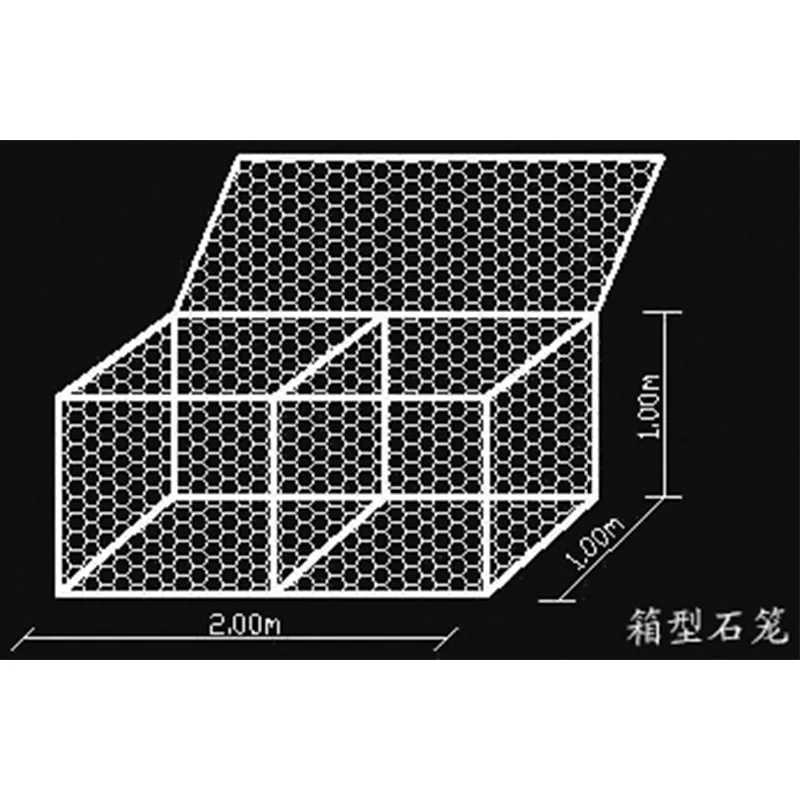

The versatility of cut wire products makes them invaluable across multiple industries. In construction and manufacturing, cut wire is used for applications such as fencing, reinforcement for concrete, and the creation of various fixtures and components. For example, cut wire is vital in producing welded wire mesh, which provides structural support and safety in construction projects.

cut wire factory

In the automotive industry, cut wires are integral in the manufacturing of components such as springs and cables. The electronics sector, too, relies heavily on cut wires for making connections within devices, ensuring both functionality and safety. Additionally, cut wire is utilized in craft and hobby industries, where it serves as the backbone for artistic creations and DIY projects.

Economic Impact

The cut wire industry significantly contributes to the global economy. As demand for metal products continues to grow in tandem with industrialization and urbanization, cut wire factories play a crucial role in meeting these needs efficiently. By providing high-quality cut wires, factories enable manufacturers to operate smoothly, thus enhancing productivity and profitability.

Moreover, cut wire factories create job opportunities, from skilled labor to management positions, bolstering local economies. The factories often invest in advanced machinery and technology, demonstrating a commitment to innovation and efficiency while contributing to sustainable manufacturing practices.

Challenges and Future Perspectives

Despite their importance, cut wire factories face challenges, including fluctuating raw material prices and competition from cheaper imports. To stay competitive, factories must adopt lean manufacturing practices, invest in technology, and prioritize sustainability. Recycling scrap wire and utilizing eco-friendly materials are steps that can not only cut costs but also align with the growing emphasis on environmental responsibility.

Looking ahead, the future of cut wire factories appears promising. With advancements in automation, factories can increase productivity and reduce labor costs. Additionally, the growing trend towards customized products will pave the way for cut wire manufacturers to innovate and tailor their offerings to meet specific market needs.

Conclusion

Cut wire factories are vital players in the manufacturing landscape, providing essential products that support various industries. As they navigate challenges and embrace opportunities for innovation, these factories will continue to be key contributors to economic growth and technological advancement in the manufacturing sector. Understanding their role and significance can help underscore the critical nature of this industry, ensuring it receives the recognition it rightly deserves.

-

Weather Resistance Properties of Quality Roofing Nails

NewsAug.01,2025

-

How Galvanised Iron Mesh Resists Corrosion in Harsh Environments

NewsAug.01,2025

-

Creative Landscaping Uses for PVC Coated Wire Mesh Panels

NewsAug.01,2025

-

Common Wire Nail Dimensions and Their Specific Applications

NewsAug.01,2025

-

Choosing the Right Welded Wire Sheets for Agricultural Fencing

NewsAug.01,2025

-

Anti - Climbing Features of Razor Wire Barriers

NewsAug.01,2025