Foglio di rete elettrosaldata

Welded Wire Mesh Sheet Sizes

Materials: Gal. Iron wire (Hot dipped galvanized and Electric galvanized), stainless steel wire, PVC coated wire mesh

Patterns: Welded before weaving, after weaving, galvanized before weaving, and after weaving in square opening or rectangular.

Usi: edilizia, recinzioni, alimentazione e protezione.

Advantages of Using Welded Mesh Sheets

One of the primary advantages of welded mesh sheets is their exceptional durability. Constructed from high-quality steel wires, these sheets are welded at each intersection, providing a robust structure that can withstand heavy loads and adverse conditions. This strength makes them ideal for reinforcing concrete and supporting various structures, which is crucial in applications such as foundations, pavements, and retaining walls.

Additionally, welded mesh sheets excel in terms of ease of installation. The sheets come in pre-fabricated sizes, minimizing on-site labor and reducing installation time. This efficiency is especially beneficial in large-scale projects where timelines are critical. By simplifying the installation process, welded mesh sheets help streamline construction schedules, ultimately reducing overall project costs.

Another significant advantage is the flexibility they offer in design configurations. Welded mesh sheets can be tailored to meet specific project requirements, making them suitable for a wide range of applications, including security fencing, livestock enclosures, and industrial partitions. This adaptability allows engineers and architects to create custom solutions that fit various site conditions and specifications.

Moreover, welded mesh sheets are also resistant to corrosion, especially when coated with protective finishes. This feature extends their lifespan, making them a cost-effective investment over time. By reducing the need for frequent replacements and repairs, welded mesh sheets contribute to sustainability in construction practices.

Welded Mesh Sheets for Security and Fencing

In an ever-evolving landscape of security fencing solutions, welded mesh sheets have emerged as a cornerstone in providing robust protection for various applications. Composed of intertwined wires that are welded together at their intersections, these sheets stand out for their durability and structural integrity, making them an ideal choice for both residential and commercial purposes.

Welded mesh sheets offer a versatile fencing solution, available in various sizes, materials, and finishes to suit diverse needs. They are particularly valued for their strength; the welding process enhances the mesh's resistance to deformation and harsh environmental conditions, ensuring long-lasting performance. Additionally, their uniform design provides an aesthetically pleasing appearance while maintaining visibility, which is especially beneficial in areas where surveillance is a priority.

One of the primary applications of welded mesh sheets is in security fencing, where the need for protection against trespassing and vandalism is paramount. Their robust construction is capable of withstanding attempts at forced entry, making them a preferred choice for securing commercial properties, warehouses, and industrial sites. Moreover, these sheets can also be integrated with additional security features such as barbed wire or electric fencing to enhance their protective capabilities.

In residential settings, welded mesh sheets serve as effective fencing solutions for gardens and yards, providing a safe boundary that deters intruders while allowing homeowners to enjoy unobstructed views. Furthermore, these sheets can be customized to accommodate gates and other entrance structures, ensuring seamless integration into existing fencing systems.

Welded Mesh Sheets for Industrial and Commercial Use

Welded mesh sheets are essential materials in a wide variety of industrial and commercial applications. Known for their durability, versatility, and cost-effectiveness, these mesh sheets are used in industries ranging from construction to manufacturing, agriculture, and more. Whether for reinforcement, safety, or structural support, welded mesh sheets offer an ideal solution to meet the demanding needs of industrial and commercial environments.

1. Industrial Applications of Welded Mesh Sheets

Welded mesh is widely used in industrial settings for various purposes, primarily for its strength and ability to withstand harsh environments. Some of the key industrial applications include:

Reinforcement in Construction Projects: In concrete reinforcement, welded mesh sheets are used to provide structural integrity and improve the strength of buildings, bridges, and roads. The mesh’s uniform grid pattern ensures even load distribution, reducing the risk of cracking or structural failure.

Screening and Sorting in Manufacturing: The welded mesh is used in the manufacturing and recycling industries for screening and sorting materials. Its ability to handle heavy loads and resist wear and tear makes it an excellent choice for separating materials, whether in mining, construction, or material processing.

Filtration Systems in Heavy Industry: Welded wire mesh sheets are commonly used in filtration applications, such as for air, water, or oil filtration in industrial plants. The mesh provides a reliable barrier while allowing fluid flow, making it essential for processes in industries such as automotive, oil & gas, and chemical processing.

2. Welded Mesh Sheets in Commercial Use

In commercial settings, welded mesh sheets are used for a variety of functional and decorative purposes, as well as for enhancing security. Some of the most notable commercial applications include:

Security Fencing and Barriers: Commercial facilities, including warehouses, factories, and retail outlets, rely on welded mesh sheets for perimeter fencing and security barriers. The mesh’s robust structure prevents unauthorized access, provides clear visibility, and allows for easy monitoring of the premises. It is commonly used for high-security applications in prisons, military installations, and industrial complexes.

Storage and Shelving Systems: Welded mesh sheets are increasingly being used in commercial shelving systems, such as for storage racks in warehouses and distribution centers. The mesh design allows for easy airflow, prevents dust accumulation, and enhances the structural integrity of the shelves.

Retail Display Fixtures: Welded mesh is often used in the retail industry for display racks and shelving units. The open grid design is ideal for displaying products in an organized manner while allowing for ventilation, which is particularly important for items like textiles or electronics.

Welded Mesh Sheet Specification Guide: From ¼" Mesh to Industrial Heavy-Duty Sizes

Selecting the right specifications for welded mesh sheets is critical for ensuring optimal performance in applications ranging from security fencing to industrial reinforcement. YISIZHE, a trusted manufacturer of welded mesh panels, offers a diverse range of precision-engineered products designed to meet residential, commercial, and industrial needs. Below is a detailed breakdown of key specifications to help you choose the perfect solution.

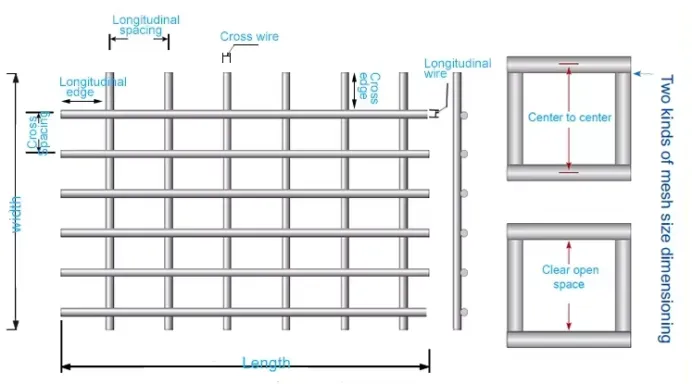

1. Mesh Opening Sizes: Tailored for Every Use Case

Our welded mesh sheets come in multiple mesh sizes, each optimized for specific functions:

¼"×¼" (6mm×6mm): Fine mesh ideal for pet enclosures, insect screens, or decorative barriers, providing protection against small pests while maintaining visibility.

½"×½" (13mm×13mm): Versatile for garden fencing, poultry nets, and window guards, balancing security with ease of installation for weld mesh fence panels.

1"×1" (25mm×25mm): Common in livestock fencing, warehouse partitions, and machine guards, offering robust strength for medium-duty applications.

2"×2" (50mm×50mm)–4"×4" (100mm×100mm): Heavy-duty sizes designed for industrial security, construction site barriers, and large animal enclosures, capable of withstanding high impact and harsh conditions.

2. Wire Gauge (BWG) & Thickness

Wire gauge determines the mesh’s rigidity and load-bearing capacity:

BWG 24 (0.56mm): Thin, flexible wire suitable for light-duty mesh welded panels like indoor partitions or retail displays.

BWG 20 (0.91mm): Medium thickness for general-purpose fencing, garden edging, and weld mesh panels for sale in residential projects.

BWG 16 (1.6mm)–BWG 12 (2.6mm): Thick, durable wire for industrial-grade welded wire sheets, used in warehouse rack reinforcement, heavy machinery guards, and anti-vandal fencing.

3. Material Options: Corrosion Resistance for Every Environment

Galvanized Steel: Hot-dip galvanized (≥240g/m² zinc coating) for superior outdoor durability (10–15 years), ideal for metal mesh panels for fencing in coastal or humid areas.

PVC-Coated: A 0.2–0.4mm PVC layer adds UV and chemical resistance, perfect for weld mesh fence panels for sale in agricultural settings (resists animal waste corrosion) or decorative applications (available in green, black, or custom colors).

Stainless Steel (304/316): Ultimate corrosion resistance for extreme environments, such as marine projects or food-grade industrial filters.

4. Panel Dimensions & Customization

Standard Sizes:

Rolls: Widths from 3ft (0.9m) to 6ft (1.8m), lengths up to 100ft (30m) for easy installation of weld mesh panels for sale.

Flat Panels: Pre-cut to sizes like 4ft×8ft (1.2m×2.4m), ready for immediate use in construction or security projects.

Custom Solutions: Tailor-made welded mesh panels in unique sizes, mesh openings, or wire gauges to meet specific project requirements—from intricate architectural screens to massive industrial partitions.

Why Choose YISIZHE’s Welded Mesh Sheets?

Precision Welding: Automated resistance welding creates strong, uniform joints that are stronger than the wire itself, eliminating loose wires in high-stress applications.

Direct Manufacturer Pricing: Buy weld mesh fence panels for sale directly from the factory, ensuring competitive prices without compromising on quality.

Quality Assurance: Every batch is tested for wire tensile strength and coating adhesion, complying with ASTM and ISO standards for reliability you can trust.

Whether you need fine weldmesh sheets for pet safety or heavy-duty metal mesh panels for fencing for industrial security, YISIZHE has the perfect specifications to meet your needs. Our team of experts is ready to help you select the right product or create a custom solution. Contact us today to explore our welded mesh panels and experience the difference of manufacturer-direct quality and service.

Weldmesh Sheets vs. Woven Mesh Sheets: Strength and Cost-Effectiveness Comparison Analysis

Choosing between welded mesh and woven mesh depends on your project’s needs for strength, durability, and budget. As a leading manufacturer of welded mesh panels and related solutions, YISIZHE breaks down the key differences to help you make an informed decision.

1. Manufacturing Process: Welded Joints vs. Twisted Intersections

Welded Mesh: Produced via automated resistance welding, fusing wire intersections at high temperatures to form solid, permanent joints. This creates weldmesh sheets with uniform, rigid structures ideal for load-bearing applications.

Woven Mesh: Constructed by twisting wires at intersections without welding, resulting in a more flexible but less rigid grid. While suitable for dynamic environments, it lacks the joint strength of welded wire sheets.

2. Tensile Strength & Structural Rigidity

Welded Mesh Advantage:

Weld points are stronger than the wire itself, making welded mesh panels highly resistant to pulling, cutting, or pressure—critical for security fencing, concrete reinforcement, or metal mesh panels for fencing in high-risk areas.

Maintains shape under heavy loads, reducing the risk of deformation in industrial partitions or warehouse racking.

Woven Mesh Limitation:

Twisted joints can loosen over time under stress, making it less suitable for heavy-duty use like weld mesh fence panels for sale in commercial projects.

3. Corrosion Resistance & Lifespan

Coating Compatibility:

Both types can be galvanized or PVC-coated, but welded mesh’s solid joints prevent coating cracks during installation, extending protection in harsh environments. YISIZHE’s hot-dip galvanized weld mesh panels for sale offer 10–15 years of outdoor durability, vs. woven mesh’s 5–10 years in similar conditions.

Stainless Steel Options:

Welded stainless steel mesh (304/316) outperforms woven versions in extreme corrosion (e.g., marine projects), thanks to seamless welded joints that resist saltwater intrusion.

4. Cost-Effectiveness: Initial Investment vs. Long-Term Value

Welded Mesh:

Higher upfront cost due to precision welding, but lower long-term maintenance—ideal for projects prioritizing longevity, like industrial security or infrastructure reinforcement.

Woven Mesh:

Cheaper initially, but frequent replacements for loose wires or damaged joints increase lifecycle costs, making it better for temporary or low-stress uses (e.g., garden fencing).

5. Application Scenarios: When to Choose Which

Opt for Welded Mesh if you need:

High security (weld mesh fence panels for sale for prisons, factories)

Structural reinforcement (concrete slabs, retaining walls)

Heavy-duty industrial screening (mining, agriculture)

Opt for Woven Mesh if you need:

Flexible barriers (animal enclosures, temporary partitions)

Aesthetic applications (decorative screens, plant supports)

YISIZHE’s Recommendation: Strength Meets Value

While woven mesh has its uses, welded mesh offers superior performance in most demanding scenarios. Our welded mesh panels feature:

Robust Welding: Automated processes ensure 100% joint integrity, surpassing ASTM standards for tensile strength.

Custom Solutions: Tailored wire gauges, mesh sizes, and coatings to match your project’s exact needs—whether for weld mesh fence panels for sale or industrial-grade mesh welded panels.

Factory-Direct Pricing: Competitive costs without compromising on the durability that welded mesh is known for.

In summary, choose welded mesh for strength, longevity, and security; choose woven mesh for flexibility and light-duty tasks. For projects where performance matters, YISIZHE’s welded mesh panels deliver unmatched reliability and cost-effective durability. Contact us today to discuss which solution is right for you.

Barbed Wire Specification Chart: B.W.G Wire Gauge vs. 3"–6" Thorn Distance Relationship

Understanding the correlation between B.W.G wire gauge and thorn distance is essential for selecting the right barbed wire for security, agricultural, or industrial applications. As a leading barbed wire manufacturer, YISIZHE presents a detailed specification guide to help you match product performance with project requirements.

1. B.W.G Wire Gauge: Defining Strength & Rigidity

B.W.G (British Wire Gauge) measures wire thickness, directly impacting the mesh’s tensile strength and durability:

12×12 B.W.G (2.6mm): Heavy-duty high tensile barbed wire ideal for prison perimeters or industrial security fences, resisting cutting and vandalism.

14×14 B.W.G (1.63mm): Medium thickness for agricultural boundaries and livestock enclosures, balancing strength with cost-effectiveness.

15.5×15.5 B.W.G (1.27mm): Light-duty gauge suitable for temporary fencing or garden barriers, easy to install but less resistant to heavy impact.

2. Thorn Distance: 3"–6" and Application Scenarios

Thorn spacing affects the wire’s anti-intrusion capability and visual deterrence:

3" (76mm) Thorn Distance: Dense thorns for maximum security in types of barbed wire like razor wire hybrids, perfect for high-risk areas requiring extreme protection.

4" (102mm) Thorn Distance: Standard spacing for general-purpose security fencing, commonly used in commercial properties or railway boundaries.

5"–6" (127–152mm) Thorn Distance: Wider spacing for agricultural or ranch fencing, reducing material cost while maintaining animal containment.

3. Material Options for Enhanced Performance

Galvanized Steel: Hot-dip galvanized barbed wire (zinc coating ≥240g/m²) offers 10–15 years of outdoor durability, resisting rust in humid or coastal environments.

Stainless Steel Barbed Wire: 304/316 grade stainless steel for ultimate corrosion resistance, ideal for marine projects, food processing facilities, or harsh chemical environments.

PVC-Coated Variants: A 0.2–0.4mm PVC layer adds UV protection and color customization (green/black), suitable for landscape-integrated fencing or animal husbandry.

4. YISIZHE’s Customization Capabilities

As a trusted barbed wire manufacturer, we offer:

Tailored Combinations: Match specific B.W.G gauges (12–19) with thorn distances (3"–8") to meet unique project needs, from military-grade security to rural boundary marking.

High Tensile Strength: Our high tensile barbed wire exceeds ASTM standards for wire elongation, ensuring minimal sagging even under heavy loads.

Quality Assurance: Every batch is tested for wire tensile strength and zinc coating adhesion, delivering reliable performance across types of barbed wire configurations.

Whether you need dense-thorn barbed wire for perimeter security or lightweight gauges for agricultural use, YISIZHE’s specification chart helps you make an informed choice. Contact us today to discuss how our precision-engineered solutions—including stainless steel barbed wire and high-tensile variants—can enhance your project’s safety and longevity.

Barbed Wire Twisting Techniques: Strength Comparison of Positive, Reverse, and Alternating Twists

The twisting method of barbed wire is a critical factor in determining its tensile strength, node stability, and suitability for various security and fencing applications. As a leading barbed wire manufacturer, YISIZHE specializes in three primary twisting techniques—positive twist, reverse twist, and alternating twist—each engineered to balance strength, durability, and cost-effectiveness. Below is a detailed analysis of their technical characteristics and real-world applications.

1. Positive Twist: Single-Direction Simplicity

How It’s Made: Wires are twisted uniformly in one direction (clockwise or counterclockwise), forming barbs at consistent intervals along the main wire.

Strength Profile:

Offers moderate tensile strength, typically resisting 1,500–2,000 pounds of pulling force—suitable for types of barbed wire used in low-to-medium security settings.

Node connections are stable under normal tension but may loosen slightly over time in high-stress environments.

Best For:

Agricultural fencing (livestock containment, ranch boundaries) where basic security and cost-efficiency are priorities.

Temporary barriers or garden edging that require easy installation and lightweight durability.

2. Reverse Twist: Bidirectional Tension Reinforcement

How It’s Made: Barbs are formed by twisting the wire in opposite directions at each intersection, creating a tighter interlock between the main wire and barb points.

Strength Profile:

Delivers higher tensile strength (2,000–2,500 pounds), making it ideal for high tensile barbed wire in commercial or industrial applications.

Reduces the risk of barb detachment under sustained pressure, providing superior resistance to animal impact or minor vandalism.

Best For:

Medium-security perimeters (railway lines, private property enclosures) that require long-lasting durability without excessive cost.

Fencing in regions with moderate weather extremes, where a balance of strength and weather resistance is essential.

3. Alternating Twist (Double Twist): Ultimate Structural Rigidity

How It’s Made: Combines positive and reverse twists in an alternating pattern, locking each barb with dual-directional tension for maximum node stability.

Strength Profile:

Provides the highest tensile strength (2,500–3,000 pounds), making it the go-to choice for security barbed wire in high-risk zones.

Virtually eliminates node loosening, ensuring barbs remain sharp and intact even after years of exposure to harsh weather, heavy loads, or deliberate tampering.

Best For:

High-security environments (prisons, military bases, critical infrastructure) where anti-intrusion and long-term reliability are non-negotiable.

Pairing with stainless steel barbed wire for coastal or corrosive environments, as the robust twist enhances resistance to saltwater or chemical damage.

Key Differences at a Glance

Tensile Strength: Alternating twist > Reverse twist > Positive twist

Node Stability: Alternating twist (virtually no looseness) outperforms reverse twist (minimal movement) and positive twist (moderate flexibility).

Cost vs. Performance: Positive twist is most budget-friendly for basic needs; alternating twist offers the best long-term value in high-stakes security.

Material Compatibility: All twists can be galvanized, PVC-coated, or made from stainless steel, but alternating twist maximizes the benefits of premium materials like stainless steel barbed wire.

Why YISIZHE Leads in Twisting Technology

As a trusted barbed wire manufacturer, we leverage decades of expertise to:

Customize for Your Needs: Recommend positive twist for agricultural simplicity, reverse twist for commercial durability, and alternating twist for impenetrable security.

Optimize Material Synergy: Pair twisting techniques with high-tensile steel or stainless steel to enhance performance in extreme conditions—e.g., alternating-twist stainless steel barbed wire for marine applications.

Guarantee Quality: Every batch undergoes rigorous tension testing and salt-spray corrosion trials to meet or exceed ASTM and ISO standards, ensuring your fencing solution performs as promised, year after year.

Choosing the right twisting technique ensures your barbed wire aligns with your project’s security level, budget, and environmental demands. Whether you need affordable agricultural fencing or indestructible high-security barriers, YISIZHE’s precision-engineered solutions—backed by expert advice on types of barbed wire—deliver the strength and reliability your project deserves. Contact us today to discuss how our twisting technologies can elevate your security infrastructure.

Notizie correlate