Des . 20, 2024 11:40 Back to list

ss wire mesh manufacturers

The Importance of SS Wire Mesh Manufacturers in Modern Industry

Stainless steel (SS) wire mesh is an essential component in various industries, ranging from construction and agriculture to pharmaceuticals and food processing. Its unique properties, such as corrosion resistance, strength, and versatility, make it a preferred choice for numerous applications. In this article, we will explore the critical role played by SS wire mesh manufacturers and why they are indispensable to modern industries.

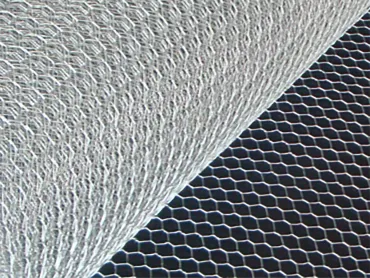

Understanding Stainless Steel Wire Mesh

Stainless steel wire mesh is made from a series of woven wires that create a sturdy and resilient material. It is known for its durability and can withstand harsh environmental conditions, making it an ideal choice for both indoor and outdoor applications. The stainless steel used in the mesh can vary in grade, with 304 and 316 being the most common. Grade 304 offers good corrosion resistance, while grade 316 is designed for more demanding and corrosive environments.

Applications of SS Wire Mesh

1. Construction and Architectural Design In the construction industry, SS wire mesh serves multiple purposes. It is often used in concrete reinforcement, helping to enhance the structural integrity of buildings. Additionally, it is employed in railings, partitions, and decorative elements, where both aesthetic and functional qualities are required.

2. Filtration and Separation SS wire mesh is a vital component in filtration applications, including water purification and air filtration systems. It effectively separates solid particles from liquids and gases, ensuring that the end product meets quality standards. This is particularly important in industries such as pharmaceuticals, where purity is paramount.

3. Agriculture Farmers also rely on stainless steel wire mesh for various purposes, including fencing, animal enclosures, and irrigation systems. Its ability to withstand exposure to moisture and chemicals makes it an ideal choice for outdoor agricultural applications.

4. Food Processing The food industry frequently utilizes SS wire mesh due to its hygienic properties and resistance to rust and corrosion. It is used in equipment, such as sieves, filters, and conveyors, ensuring contaminants don’t compromise food safety.

5. Environmental Applications Given its durability and resilience, SS wire mesh plays a crucial role in environmental applications, such as erosion control and sediment filtration. It helps manage stormwater runoff and protects waterways from sediment and pollutants.

ss wire mesh manufacturers

The Role of SS Wire Mesh Manufacturers

The efficiency and reliability of stainless steel wire mesh can only be ensured through the expertise and precision offered by SS wire mesh manufacturers. These manufacturers are responsible for producing high-quality products that meet specific industry standards and customer requirements. Here are several key functions they perform

1. Customization Manufacturers can tailor wire mesh products to fit the unique needs of various industries. This includes adjusting the mesh size, wire diameter, and material grade, ensuring that the final product meets the specific requirements of the application.

2. Quality Control Reputable SS wire mesh manufacturers implement rigorous quality control processes to guarantee that their products are free from defects. This includes conducting thorough inspections throughout the manufacturing process and adhering to industry certifications.

3. Research and Development Continuous innovation is crucial in meeting the evolving demands of the market. Leading manufacturers invest in research and development to create new products and improve existing ones, ensuring that they stay ahead of technological advancements.

4. Supply Chain Management Efficient supply chain management ensures that manufacturers can deliver products on time and at competitive prices. This is essential in industries where delays can lead to significant financial losses.

5. Customer Service and Support A strong support system is necessary for assisting customers with inquiries, technical specifications, and installation recommendations. Manufacturers that provide excellent customer service help clients make informed decisions and improve their overall experience.

Conclusion

The importance of SS wire mesh manufacturers cannot be overstated. Their role in producing high-quality, reliable products is essential for the smooth operation of various industries. With their commitment to customization, quality control, and innovation, these manufacturers are integral to advancing technology and practices in many sectors. As industries continue to evolve, the contributions of SS wire mesh manufacturers will undoubtedly remain critical in meeting the demands of the modern world.

-

The Power of Iron Wire: A Versatile Solution for Multiple Applications

NewsJun.19,2025

-

Reliable Hydraulic Fittings for Optimal Performance

NewsJun.19,2025

-

Quality Roofing Nails for Every Project

NewsJun.19,2025

-

Hexagonal Wire Mesh: Versatile and Durable Solutions for Every Project

NewsJun.19,2025

-

Enhancing Security with Barbed Wire Solutions

NewsJun.19,2025

-

Binding Wire: The Essential Material for a Variety of Applications

NewsJun.19,2025