Okt . 31, 2024 17:35 Back to list

Understanding Hydraulic Hose Ferrules and Their Importance in Fluid Conveyance Systems

Understanding Hydraulic Hose Ferrules An Essential Component in Fluid Power Systems

Hydraulic systems play a crucial role in various industrial applications, from construction machinery to agricultural equipment. At the heart of these systems is the hydraulic hose, which is responsible for transporting hydraulic fluid under high pressure. One of the often-overlooked components essential to the integrity and functionality of a hydraulic hose is the hydraulic hose ferrule.

A hydraulic hose ferrule is a metal sleeve that is crimped onto the ends of a hydraulic hose. This critical component serves several important functions. Firstly, it creates a secure connection between the hose and the fitting, preventing leaks that could compromise the entire hydraulic system. The ferrule helps achieve this by enclosing the hose, which allows the hydraulic fluid to flow seamlessly through the system without escape.

Ferrules are typically made from materials such as brass or stainless steel, known for their high strength and resistance to corrosion. The choice of material plays a vital role in the ferrule's performance, especially in demanding environments where exposure to harsh chemicals or extreme temperatures is common. The durability of the ferrule directly impacts the lifespan of the hydraulic hose assembly.

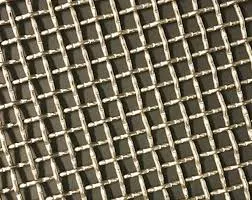

hydraulic hose ferrule

The manufacturing process of hydraulic hose ferrules involves precision engineering to ensure they fit securely onto a variety of hose sizes and types. Properly crimped ferrules are crucial, as improper crimping can lead to hose failure due to excessive pressure. Therefore, it is essential to use specialized crimping tools designed for the specific ferrule and hose combination.

Moreover, different applications may require different types of ferrules. For instance, ferrules designed for high-pressure hydraulic systems are engineered to withstand greater forces than those used in low-pressure applications. Understanding the specific requirements of your hydraulic system is vital when selecting the appropriate ferrule.

Maintenance is also an important aspect of hydraulic systems. Regular inspections of the hose assembly, including the ferrule, can help identify potential issues before they escalate. Signs of wear, such as cracking or deformity in the ferrule, should be addressed promptly to ensure the continued efficiency and safety of the hydraulic system.

In conclusion, hydraulic hose ferrules are integral to the integrity and functionality of hydraulic systems. Their role in securing connections and preventing leaks highlights their importance in maintaining system performance and safety. By understanding their function, choosing the right type, and conducting regular maintenance, operators can ensure that their hydraulic systems operate efficiently and reliably for years to come. Whether in construction, agriculture, or manufacturing, a strong and secure hydraulic hose ferrule is a small, yet vital piece of the larger fluid power puzzle.

-

Weather Resistance Properties of Quality Roofing Nails

NewsAug.01,2025

-

How Galvanised Iron Mesh Resists Corrosion in Harsh Environments

NewsAug.01,2025

-

Creative Landscaping Uses for PVC Coated Wire Mesh Panels

NewsAug.01,2025

-

Common Wire Nail Dimensions and Their Specific Applications

NewsAug.01,2025

-

Choosing the Right Welded Wire Sheets for Agricultural Fencing

NewsAug.01,2025

-

Anti - Climbing Features of Razor Wire Barriers

NewsAug.01,2025