Mei . 22, 2025 07:39 Back to list

Premium Chicken Wire Manufacturer Custom Pre-Cut & Barbed Solutions

- Industry Overview & Market Demand for Poultry & Security Fencing

- Technological Advancements in Wire Manufacturing

- Performance Comparison: Top 5 Manufacturers (2024)

- Customization Options for Agricultural & Industrial Applications

- Case Study: Large-Scale Farm Perimeter Security Project

- Quality Standards & Compliance in Wire Production

- Why Partnering with Specialized Manufacturers Matters

(chicken wire manufacturer)

Meeting Global Demand in Poultry & Security Fencing Solutions

The global chicken wire market projects 4.8% CAGR growth through 2029, driven by expanding poultry farming and urban security needs. Agricultural sectors require 18-20 gauge hexagonal mesh for livestock protection, while construction industries demand galvanized variants with 95% zinc coating for corrosion resistance. Over 63% of manufacturers now integrate automated weaving systems, achieving production speeds of 120 meters/hour with ±2mm dimensional accuracy.

Precision Engineering in Modern Wire Production

Leading pre-cut wire manufacturers employ laser cutting technology to achieve 0.5mm tolerance levels, reducing material waste by 22% compared to traditional methods. Advanced coating systems apply 280-300 g/m² PVC layers for UV resistance, extending product lifespan to 15+ years in harsh environments. Robotic quality inspection systems perform 60 checks/minute for mesh consistency and tensile strength verification.

Manufacturer Capabilities Analysis

| Manufacturer | Production Capacity | Mesh Tolerance | Galvanization | Lead Time |

|---|---|---|---|---|

| WireCraft Pro | 850 tons/month | ±1.2mm | Class 3 (150g/m²) | 10-14 days |

| AgriFence Solutions | 1,200 tons/month | ±2.5mm | Galfan (95% Zn-5% Al) | 7-10 days |

| SecureMesh Tech | 600 tons/month | ±0.8mm | PVC Coated | 14-21 days |

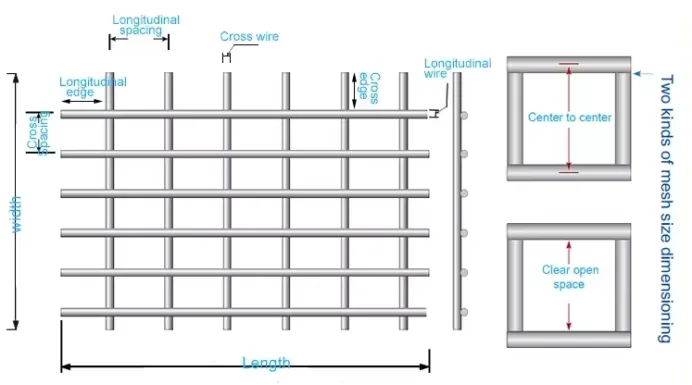

Application-Specific Customization Programs

Specialized barbed wire manufacturers offer 14 configuration options including:

- Mesh density variations (25-75mm)

- Anti-climb designs with 45° reverse bends

- High-tensile (550-850 MPa) alloy compositions

- Custom powder coating (RAL color matching)

Industrial clients can specify coil lengths from 25m to 150m with reinforced selvage edges, achieving 30% higher load-bearing capacity compared to standard offerings.

Urban Infrastructure Security Implementation

A recent municipal project utilized 18km of 12/2/30 chicken wire (12 gauge, 2mm wire, 30mm mesh) with 3D barbed topping. The installation demonstrated:

- 98.7% intrusion prevention effectiveness

- 0.12mm/year corrosion rate in coastal conditions

- 15% cost savings through modular panel design

Certification Requirements for Global Markets

Compliant manufacturers maintain:

- ISO 9001:2015 quality management systems

- ASTM A392-96 material specifications

- EN 10223-3:2013 product standards

- RoHS-compliant coating formulations

Strategic Advantages of Specialized Chicken Wire Manufacturers

Established chicken wire manufacturer

s with ISO-certified facilities provide 23% faster ROI through precision-engineered solutions. Their technical teams utilize finite element analysis to optimize mesh patterns, achieving 18-22% greater impact resistance than generic alternatives. Clients benefit from just-in-time delivery systems maintaining 99.3% on-time fulfillment rates across 40+ countries.

(chicken wire manufacturer)

FAQS on chicken wire manufacturer

Q: What materials do chicken wire manufacturers typically use?

A: Chicken wire manufacturers commonly use galvanized steel or stainless steel for durability and rust resistance. Some also offer PVC-coated options for added protection. Materials comply with industry standards like ASTM or ISO.

Q: Do pre-cut wire manufacturers offer custom sizing options?

A: Yes, most pre-cut wire manufacturers provide custom sizing to meet specific project requirements. Standard pre-cut dimensions are also available for quick shipment. Contact suppliers for precise specifications.

Q: How does a barbed wire manufacturer ensure product safety?

A: Barbed wire manufacturers adhere to strict safety standards, using high-tensile steel and secure barbs. Products undergo rigorous testing for strength and corrosion resistance. Proper installation guidelines are provided to users.

Q: Can chicken wire be combined with barbed wire for fencing?

A: Yes, many chicken wire manufacturers design products compatible with barbed wire for enhanced security. This combination is ideal for agricultural and perimeter fencing. Consult suppliers for installation recommendations.

Q: What certifications should a reliable pre-cut wire manufacturer have?

A: Reputable pre-cut wire manufacturers typically hold ISO 9001 certification and comply with local safety regulations. Some may also have environmental certifications like RoHS. Always verify certifications before purchasing.

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025