Jan . 15, 2025 05:41 Back to list

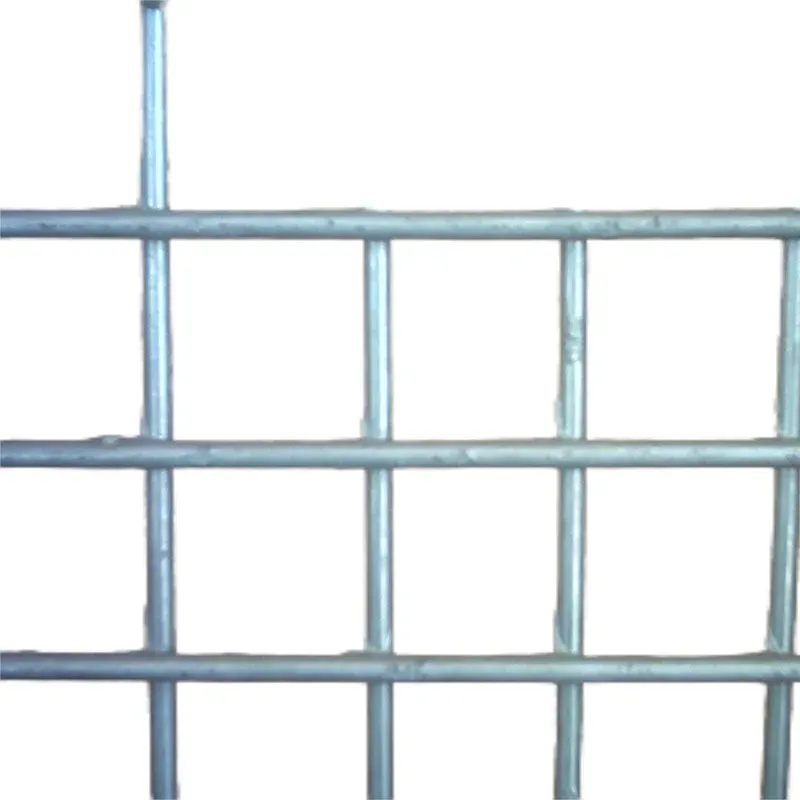

square welded wire mesh

Square welded wire mesh, a staple in various industries, boasts unparalleled versatility and strength, making it an essential material for construction and manufacturing experts worldwide. As experienced users and purveyors of square welded wire mesh, we've amassed significant insights into its myriad applications and advantages, underscoring its authority in the field.

In manufacturing, the expertise embedded in square welded wire mesh's design allows for its application in producing high-security fences, machine guards, and ventilation screens. Such usage demands precision and unwavering quality, elements that this mesh consistently delivers. Manufacturing experts attest to the mesh's durability and security, reassuring stakeholders of its effectiveness in protecting valuable assets. Cost-effectiveness further cements square welded wire mesh’s standing as a preferred material. Its installation simplicity reduces labor time and expense, providing economic advantages without compromising on quality or safety. This expert-backed balance between cost and performance enhances the mesh's status as a prudent investment in long-term projects. Sustainability, an increasingly critical factor in material selection, enhances the product's credibility. The mesh's steel components are recyclable, appealing to environmentally conscious professionals aiming to reduce their project's carbon footprint. The mesh's longevity minimizes the need for frequent replacements, thus contributing to sustainable building practices. True experts recognize the blend of innovation and tradition encapsulated in square welded wire mesh. It combines decades of trusted application with contemporary demands for efficiency and environmental responsibility. As industries evolve, the enduring relevance and authority of square welded wire mesh continue to shine, earning ongoing trust from industry leaders and reinforcing its indispensable role.

In manufacturing, the expertise embedded in square welded wire mesh's design allows for its application in producing high-security fences, machine guards, and ventilation screens. Such usage demands precision and unwavering quality, elements that this mesh consistently delivers. Manufacturing experts attest to the mesh's durability and security, reassuring stakeholders of its effectiveness in protecting valuable assets. Cost-effectiveness further cements square welded wire mesh’s standing as a preferred material. Its installation simplicity reduces labor time and expense, providing economic advantages without compromising on quality or safety. This expert-backed balance between cost and performance enhances the mesh's status as a prudent investment in long-term projects. Sustainability, an increasingly critical factor in material selection, enhances the product's credibility. The mesh's steel components are recyclable, appealing to environmentally conscious professionals aiming to reduce their project's carbon footprint. The mesh's longevity minimizes the need for frequent replacements, thus contributing to sustainable building practices. True experts recognize the blend of innovation and tradition encapsulated in square welded wire mesh. It combines decades of trusted application with contemporary demands for efficiency and environmental responsibility. As industries evolve, the enduring relevance and authority of square welded wire mesh continue to shine, earning ongoing trust from industry leaders and reinforcing its indispensable role.

Next:

Latest news

-

Weather Resistance Properties of Quality Roofing Nails

NewsAug.01,2025

-

How Galvanised Iron Mesh Resists Corrosion in Harsh Environments

NewsAug.01,2025

-

Creative Landscaping Uses for PVC Coated Wire Mesh Panels

NewsAug.01,2025

-

Common Wire Nail Dimensions and Their Specific Applications

NewsAug.01,2025

-

Choosing the Right Welded Wire Sheets for Agricultural Fencing

NewsAug.01,2025

-

Anti - Climbing Features of Razor Wire Barriers

NewsAug.01,2025