joulu . 12, 2024 02:16 Back to list

Hydraulic Hose End Fittings for Optimal Performance and Reliability in Hose Assemblies

Understanding Hydraulic Hose End Fittings An Essential Component in Fluid Power Systems

Hydraulic systems play a crucial role in various industries, from construction to manufacturing and agriculture. At the heart of these systems lies a network of hydraulic hoses and fittings, which are essential for fluid transfer under pressure. Among these fittings, hydraulic hose end fittings are particularly significant as they connect hoses to other components, facilitating efficient fluid movement and ensuring system integrity.

What Are Hydraulic Hose End Fittings?

Hydraulic hose end fittings are specialized connectors designed to strengthen and secure the ends of hydraulic hoses. These fittings come in various shapes, sizes, and materials, tailored to meet the demands of specific applications. Common types of hose end fittings include crimped fittings, reusable fittings, and molded fittings. The choice of fitting type often depends on factors such as pressure ratings, hose specifications, and operational environment.

Types of Hydraulic Hose End Fittings

1. Crimped Fittings These are permanently attached to hoses using a crimping machine, creating a strong bond that can handle high pressures. Crimped fittings are commonly used in applications where reliability and durability are paramount.

2. Reusable Fittings Unlike crimped fittings, reusable fittings can be removed and reattached to hoses without damaging the hose material. This feature makes them ideal for applications requiring frequent maintenance or adjustments. However, proper installation is crucial, as incorrect fitting can lead to leaks or pressure loss.

3. Molded Fittings These fittings are integrated into the hose during the manufacturing process, offering a seamless connection. They provide excellent resistance to pressure and are often used in low-plumbing scenarios.

Material Selection

The material of hydraulic hose end fittings typically varies based on the application environment. Common materials include

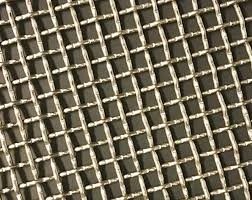

hydraulic hose end fittings

- Steel Strong and durable, steel fittings are widely used in high-pressure applications. They can be treated with various coatings to enhance corrosion resistance. - Stainless Steel Known for its resistance to rust and corrosion, stainless steel fittings are ideal for harsh environments and applications involving chemicals or moisture. - Aluminum Lightweight and resistant to corrosion, aluminum fittings are often used in lower-pressure applications or where weight is a concern.

Importance of Quality and Standards

When it comes to hydraulic hose end fittings, quality is non-negotiable. Low-quality fittings can lead to catastrophic failures, causing leaks, system downtime, or even severe accidents. It is vital to choose fittings that meet industry standards, such as those established by the Society of Automotive Engineers (SAE) or American National Standards Institute (ANSI). These standards ensure that the fittings can withstand specific pressure and temperature ratings while maintaining structural integrity.

Installation and Maintenance

Proper installation of hydraulic hose end fittings is crucial for system performance. It involves

- Selecting the Right Fitting Ensure compatibility between the hose and fitting type. - Correct Assembly Follow manufacturer guidelines for crimping or fitting installation to achieve a secure connection. - Routine Inspections Regular checks for signs of wear, corrosion, or leaks can prevent unexpected failures.

Maintaining hydraulic hose end fittings through proactive measures ensures the longevity and efficiency of hydraulic systems. This involves checking connections, tightening fittings if necessary, and replacing worn-out components promptly.

Conclusion

Hydraulic hose end fittings serve as the lifeline of hydraulic systems, enabling effective fluid transfer essential for various industrial applications. Understanding the types, materials, and importance of these fittings not only helps in selecting the right components but also in maintaining the overall efficiency and safety of hydraulic systems. Investing in high-quality fittings and adhering to proper installation and maintenance practices is vital for optimal performance and safety.

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025