helmi . 10, 2025 10:27 Back to list

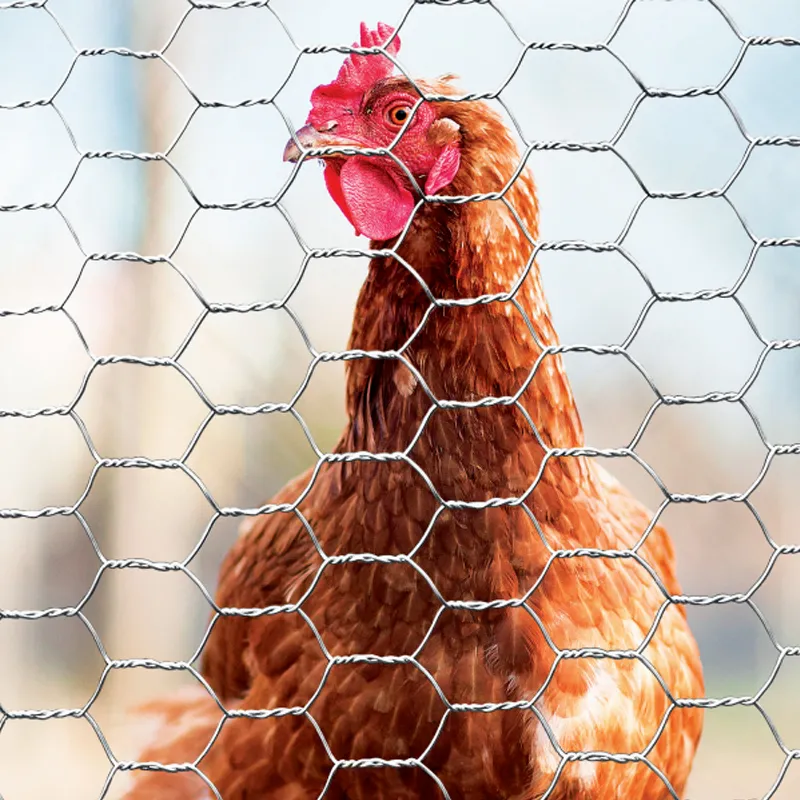

galvanized steel wire mesh

Galvanized steel wire mesh stands as a pivotal material in various industries, revered for its durability, resistance to corrosion, and versatility. With an increasing demand across sectors like construction, agriculture, and industrial settings, understanding the intrinsic qualities and applications of galvanized steel wire mesh can provide insights into why it remains a preferred choice and how it continues to evolve with technological advancements.

The expertise within the industry continually drives innovation in the development and manufacturing of galvanized steel wire mesh. New coatings and applications aim to enhance its resistance to more aggressive chemical environments, thereby widening its usability. For instance, the development of alloy coatings provides further protection and extends the application possibilities of galvanized steel wire mesh in highly corrosive environments, such as marine and chemical industries. The authoritative nature of galvanized steel wire mesh in the market is underpinned by its compliance with international standards and manufacturing processes that guarantee quality and performance. Certifying bodies and industrial standards ensure that products meet specific safety and durability benchmarks, reassuring customers of their reliability. Trustworthiness is further enhanced by the transparent manufacturing processes and rigorous testing that ensure each batch of galvanized steel wire mesh meets the stated specifications. Reputable manufacturers offer lifetime warranties on their products, underscoring their confidence in the material's longevity and performance under specified conditions. Additionally, customer testimonials and case studies provide real-world evidence of the mesh's performance, reinforcing its trustworthy reputation. In an era where environmental sustainability is a significant consideration, galvanized steel wire mesh addresses concerns over eco-friendliness. The zinc coating used in the galvanization process is non-toxic, and the steel itself is recyclable, making it a sustainable choice compared to other materials. This aspect ensures that its use not only meets current performance needs but does so responsibly without compromising future environmental health. In conclusion, galvanized steel wire mesh, with its proven track record of durability, adaptability, and reliability, stands as an essential material across industries. Its continuous development, supported by industry expertise and authoritative standards, ensures that it remains at the forefront of material solutions for emerging challenges. As industries evolve and environmental considerations gain importance, galvanized steel wire mesh's role in providing sustainable, high-performance solutions will likely expand, reinforcing its position as a material of choice.

The expertise within the industry continually drives innovation in the development and manufacturing of galvanized steel wire mesh. New coatings and applications aim to enhance its resistance to more aggressive chemical environments, thereby widening its usability. For instance, the development of alloy coatings provides further protection and extends the application possibilities of galvanized steel wire mesh in highly corrosive environments, such as marine and chemical industries. The authoritative nature of galvanized steel wire mesh in the market is underpinned by its compliance with international standards and manufacturing processes that guarantee quality and performance. Certifying bodies and industrial standards ensure that products meet specific safety and durability benchmarks, reassuring customers of their reliability. Trustworthiness is further enhanced by the transparent manufacturing processes and rigorous testing that ensure each batch of galvanized steel wire mesh meets the stated specifications. Reputable manufacturers offer lifetime warranties on their products, underscoring their confidence in the material's longevity and performance under specified conditions. Additionally, customer testimonials and case studies provide real-world evidence of the mesh's performance, reinforcing its trustworthy reputation. In an era where environmental sustainability is a significant consideration, galvanized steel wire mesh addresses concerns over eco-friendliness. The zinc coating used in the galvanization process is non-toxic, and the steel itself is recyclable, making it a sustainable choice compared to other materials. This aspect ensures that its use not only meets current performance needs but does so responsibly without compromising future environmental health. In conclusion, galvanized steel wire mesh, with its proven track record of durability, adaptability, and reliability, stands as an essential material across industries. Its continuous development, supported by industry expertise and authoritative standards, ensures that it remains at the forefront of material solutions for emerging challenges. As industries evolve and environmental considerations gain importance, galvanized steel wire mesh's role in providing sustainable, high-performance solutions will likely expand, reinforcing its position as a material of choice.

Next:

Latest news

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025