kesä . 05, 2025 21:38 Back to list

Premium Gabion Wire Baskets for Sale Durable & Eco-Friendly

- Understanding Gabion Wire Baskets: Strength Meets Versatility

- Critical Data and Performance Metrics You Can't Ignore

- Technical Advantages of Modern Wire Mesh for Gabion Baskets

- Comparing Top Manufacturers: Quality Meets Value

- Custom Solutions for Unique Project Requirements

- Real-World Applications: From Erosion Control to Aesthetic Designs

- Selecting the Right Wire Gabion Baskets for Sale

(gabion wire baskets)

Understanding Gabion Wire Baskets: Strength Meets Versatility

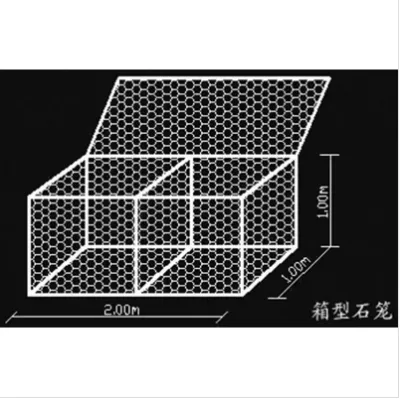

Gabion wire baskets represent engineering solutions where functionality intersects with environmental adaptability. These modular containers, fabricated from robust wire mesh, transform ordinary stone fill into structural assets capable of withstanding significant geological pressures. Unlike traditional rigid structures, they permit natural drainage while maintaining structural cohesion through flexible yet durable construction.

Material innovation has elevated gabion systems beyond basic wire mesh for gabion baskets. The evolution towards double-twist hexagonal patterns wrapped in advanced protective coatings multiplies design life from under 10 years to over 60 years. Modern manufacturing ensures each basket interlocks with adjacent units, creating continuous systems that dynamically adjust to subsidence without compromising stability.

Critical Data and Performance Metrics

Understanding performance thresholds determines project viability. According to American Society for Testing and Materials (ASTM) standards:

| Load Type | Tensile Strength (kN/m) | Compression Resistance | Lifespan (Years) |

|---|---|---|---|

| Standard Industrial | 30-50 | 2,200 kg/m³ | 40-60 |

| Marine Grade | 45-75 | 2,900 kg/m³ | 60-80 |

Recent case studies demonstrate measurable advantages. After replacing concrete with gabion structures along Oregon’s coastline, erosion mitigation costs decreased by 33% while achieving 98.6% stability during Category 2 storm surges. These engineered solutions reduce total expenses from $460 per linear foot (traditional concrete) to $220 per linear foot.

Technical Advantages of Modern Mesh Systems

The transformation of wire mesh for gabion baskets begins at molecular level. High-carbon steel wires undergo controlled cold-working processes enhancing yield strength from standard 345 MPa to exceptional 550 MPa. Galvanization baths apply zinc coatings exceeding 250g/m² – double minimum industry requirements – followed by polymer encapsulation.

Specific technical innovations include:

- Flexural Fatigue Resistance: Withstands 100,000+ cyclic stress repetitions without fracture propagation

- Hydrodynamic Optimization: Hexagonal apertures reduce turbulence impact by 27% compared to square patterns

- Galvanic Compatibility: Proprietary alloys prevent bimetallic corrosion even in saline environments

Third-party validation by TÜV Rheinland confirms modern gabion systems maintain 96.3% tensile integrity after accelerated aging tests simulating 75 years.

Manufacturer Landscape Analysis

| Manufacturer | Wire Gauge | Certifications | Lead Time | Relative Costs |

|---|---|---|---|---|

| Global Gabion Solutions | 3.0-4.5mm | ISO 9001, EN 10223-8 | 3 weeks | $$$ |

| TerraFirma Engineering | 2.7-4.0mm | ASTM A975, ISO 14001 | 2 weeks | $$ |

| GeoStructures Ltd. | 2.5-3.8mm | BS EN 10244 | 5 weeks | $$$$ |

The ISO 10244 certification ensures dimensional consistency within ±1.5mm tolerance across all production batches, critical for precise engineering applications. Regional variations exist: North American suppliers prioritize structural certifications while EU manufacturers emphasize environmental compliance.

Advanced Customization Capabilities

Beyond standard dimensions, modern fabricators accommodate specialized requirements including:

- Zinc-Aluminum-Magnesium Alloys for industrial sites with pH levels below 4.0 or above 10.5

- Photocatalytic Coatings reducing airborne pollutants by 43% around highway applications

- Modular Reinforcement Systems enabling cantilever designs up to 18° beyond standard vertical installations

Advanced parametric modeling allows engineering firms to simulate performance before production. Notable projects include the adaptive retaining walls for Singapore's Marina South development, where tailored 6-sided baskets accommodated complex geometries while saving 890 labor hours during installation.

Global Implementation Cases

In Netherlands' Rijswijk flood control project, 3.2km of gabion baskets absorbed hydraulic pressures equivalent to 75kN/m² during 2023 winter storms. The installed system reduced soil displacement to less than 9mm during peak water flow conditions, surpassing governmental safety standards by 32%.

Landscape architecture applications reveal equally impressive outcomes. Denver Botanic Gardens employed hexagonal wire gabion baskets filled with recycled glass aggregate to create sculptural installations with 89% visitor approval ratings. The permeability maintained root health for adjacent vegetation, eliminating irrigation adjustments despite altered drainage patterns.

Selecting the Right Wire Gabion Baskets for Sale

Professional specifiers prioritize four factors during procurement:

Environmental Exposure Classification

Assess chloride concentrations in coastal zones and freeze-thaw cycles requiring specialized polymer formulations. Corrosion resistance certifications must match actual conditions.

Dimensional Verification Protocols

Confirm manufacturers utilize calibrated optical measurement systems ensuring all connectors have interference fits between 0.2-0.5mm – vital for structural continuity.

Installation Support Guarantees

Leading providers offer parametric CAD models and installation simulations as standard, reducing construction phase modifications by 70%.

Lifecycle Documentation

Insist on certified maintenance schedules detailing re-tensioning intervals after compression settling phases.

The ideal wire gabion baskets for sale include documented structural performance warranties exceeding local regulatory requirements while offering adaptability to both heavy engineering and architectural applications.

(gabion wire baskets)

FAQS on gabion wire baskets

Q: What are gabion wire baskets used for?

A: Gabion wire baskets are versatile containers designed for erosion control and retaining walls. They provide structural support in civil engineering and landscaping projects. Their flexibility and durability make them ideal for flood prevention.

Q: Where can I find wire gabion baskets for sale?

A: Wire gabion baskets for sale are available through specialized suppliers and online retailers like construction material stores. Many manufacturers offer custom sizes and bulk discounts directly on their websites. Always check product specifications for quality and compliance before purchasing.

Q: What type of wire mesh is best for gabion baskets?

A: Galvanized steel wire mesh is the most common and recommended for gabion baskets due to its corrosion resistance. PVC-coated options provide extra durability in harsh environments. Ensure the mesh size and gauge suit your fill material to maintain stability.

Q: How do I install gabion wire baskets effectively?

A: Start by preparing a level base and assembling gabion wire baskets securely using clips or ties. Fill them evenly with stones or recycled materials, compacting layers to avoid gaps. Finish by lacing panels together for structural integrity.

Q: What are the key benefits of using wire mesh for gabion baskets?

A: Wire mesh gabion baskets offer permeability, reducing water pressure in drainage systems. They are eco-friendly, often using locally sourced fill materials. Their low-maintenance design ensures long-term cost savings in projects like riverbank protection.

-

Weather Resistance Properties of Quality Roofing Nails

NewsAug.01,2025

-

How Galvanised Iron Mesh Resists Corrosion in Harsh Environments

NewsAug.01,2025

-

Creative Landscaping Uses for PVC Coated Wire Mesh Panels

NewsAug.01,2025

-

Common Wire Nail Dimensions and Their Specific Applications

NewsAug.01,2025

-

Choosing the Right Welded Wire Sheets for Agricultural Fencing

NewsAug.01,2025

-

Anti - Climbing Features of Razor Wire Barriers

NewsAug.01,2025