marras . 20, 2024 05:22 Back to list

cut wire manufacturer

Understanding the Role of Cut Wire Manufacturers in Modern Industry

Cut wire manufacturers play a vital role in various industrial sectors, providing high-quality wire products that serve numerous applications. These manufacturers produce cut wires that are specifically designed for different uses, ranging from construction and engineering to crafting and automotive industries. This article delves into the significance of cut wire manufacturing, the processes involved, and the diverse applications of cut wires.

What are Cut Wires?

Cut wires are wire products that have been precisely cut to specific lengths and dimensions for a wide range of applications. Typically made from materials such as stainless steel, carbon steel, and aluminum, these wires can vary in diameter and quality based on their intended use. The cutting process can be carried out using different methods, including mechanical cutting, shearing, or laser cutting, ensuring that the finished product meets exact specifications.

The Manufacturing Process

The manufacturing of cut wires involves several stages, beginning with the selection of raw materials. Manufacturers need to consider the physical and chemical properties of the wire, which will determine its suitability for various applications. Once the appropriate material is selected, it undergoes a series of processes that include drawing, annealing, and ultimately cutting to the desired length.

1. Wire Drawing This is the first step where large coils of metal are drawn through a series of dies to produce thinner wires. The wire diameter is reduced while increasing its length. 2. Annealing Following the drawing process, wires often require annealing, a heat treatment that improves ductility and reduces hardness, making the wires easier to cut and shape.

3. Cutting The wire is then precisely cut into specified lengths. This operation can be automated for efficiency, ensuring that large volumes of cut wire can be produced in a short timeframe.

4. Finishing After cutting, some wires may require additional processes such as cleaning, coating, or packaging, depending on their end use.

Applications of Cut Wires

cut wire manufacturer

The applications of cut wires are extensive and varied

. Here are some of the primary industries that make use of cut wire products1. Construction In the construction industry, cut wires are commonly used for reinforcing concrete structures. They provide strength and stability, contributing to the safety and reliability of buildings and bridges.

2. Automotive Cut wires are essential components in many automotive parts, including springs, cables, and electrical wiring. Their ability to withstand tension and fatigue makes them suitable for various applications within vehicles.

3. Crafting and DIY Projects Hobbyists and crafters often utilize cut wires in artistic projects, jewelry making, and DIY home improvements. Their versatility and ease of use make them a popular choice for creative endeavors.

4. Industrial Applications Industries such as manufacturing, aerospace, and electronics rely on cut wires for components that require precise specifications and durability.

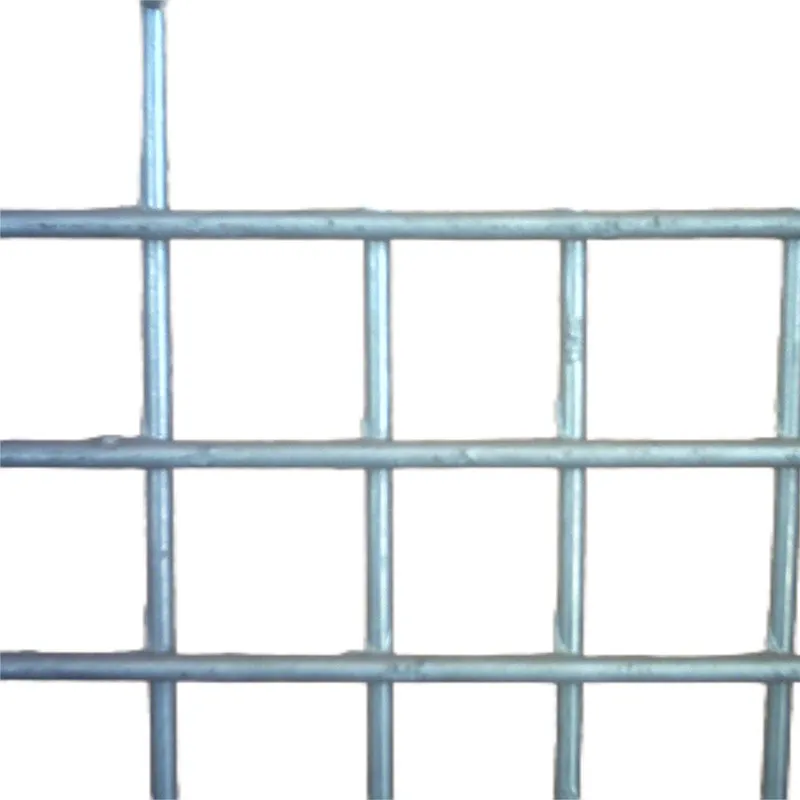

5. Security and Fencing Cut wires are also used in fencing and security applications, helping to create barriers and enclosures for safety and protection.

The Importance of Quality

The quality of cut wires is critical to their performance in any application. Manufacturers must adhere to strict quality control measures, ensuring that the wires meet industry standards and specifications. This includes testing for tensile strength, flexibility, and resistance to corrosion, among other properties. High-quality cut wires not only enhance the functionality of products but also contribute to the longevity and reliability of crucial applications.

Conclusion

Cut wire manufacturers are integral to numerous sectors, supplying essential products that facilitate various applications. By understanding the manufacturing process and the diverse uses of cut wires, industries can appreciate the significance of these seemingly simple components in modern manufacturing and craftsmanship. As technology continues to advance, the demand for high-quality cut wires is likely to grow, ensuring that manufacturers play an increasingly important role in the industrial landscape.

-

Weather Resistance Properties of Quality Roofing Nails

NewsAug.01,2025

-

How Galvanised Iron Mesh Resists Corrosion in Harsh Environments

NewsAug.01,2025

-

Creative Landscaping Uses for PVC Coated Wire Mesh Panels

NewsAug.01,2025

-

Common Wire Nail Dimensions and Their Specific Applications

NewsAug.01,2025

-

Choosing the Right Welded Wire Sheets for Agricultural Fencing

NewsAug.01,2025

-

Anti - Climbing Features of Razor Wire Barriers

NewsAug.01,2025