Dic . 23, 2024 06:46 Back to list

Innovative Solutions from Leading Cut Wire Manufacturers for Your Industrial Needs

Understanding Cut Wire Manufacturers A Key Driver in Diverse Industries

In the world of manufacturing and industry, specific materials play a crucial role in the production processes of various goods. One such essential material is cut wire, which is produced by specialized manufacturers known as cut wire manufacturers. These companies cater to a range of sectors, supplying them with high-quality wire products that are essential for both functional and aesthetic purposes.

What is Cut Wire?

Cut wire refers to metal wire that has been cut to specific lengths for use in a variety of applications. This product may be made from different materials, including stainless steel, carbon steel, galvanized steel, and other alloys. The wire can be customized in terms of diameter, length, and finish, making it suitable for a multitude of industries. Common uses of cut wire include construction, agriculture, automotive manufacturing, and home improvement.

Types of Cut Wire

Cut wire manufacturers typically offer a variety of products tailored to meet the specific needs of their clients. Some common types include

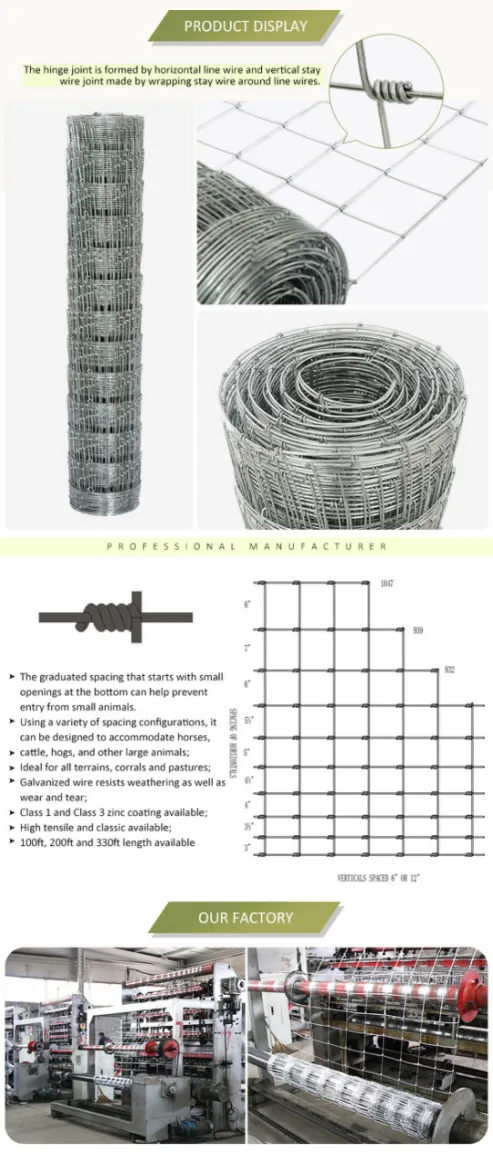

1. Construction Wire Used in concrete reinforcement, fencing, and building frameworks, construction wire is known for its strength and versatility.

2. Agricultural Wire Primarily used in farming, agriculture wire is often used in fencing, trellising, and supporting plant structures.

3. Automotive Wire This type is utilized in the automotive industry for various applications, including spring production and assembly processes.

The Role of Cut Wire Manufacturers

cut wire manufacturer

Cut wire manufacturers are vital players in the supply chain. They transform raw metal wire into useful products according to the specifications provided by their clients. This transformation occurs through a process that includes cutting, straightening, and sometimes additional treatments to enhance the material's properties, such as galvanizing for corrosion resistance.

These manufacturers serve a diverse client base, ranging from large industrial clients to small businesses and individual consumers. The versatility in production allows them to cater to unique requirements, creating custom orders that fulfill specific project demands. Moreover, they often offer additional services such as packaging and logistics to streamline the supply process for their customers.

Quality Assurance and Standards

Quality is paramount in the manufacturing of cut wire. Manufacturers adhere to stringent standards to ensure that their products meet both industry specifications and customer expectations. This involves rigorous quality control processes, including material inspections and tests for tensile strength, corrosion resistance, and other mechanical properties.

Certifications play a crucial role in demonstrating a manufacturer's commitment to quality. Many cut wire manufacturers comply with international standards such as ISO 9001, which denotes a strong focus on quality management systems. This compliance not only enhances the manufacturer's credibility but also instills confidence in clients regarding the reliability of the products.

The Future of Cut Wire Manufacturing

As industries continue to evolve, the demand for specialized cut wire products is set to increase. Innovations in materials science, as well as advances in manufacturing technologies, are expected to drive growth in this sector. Manufacturers are likely to explore eco-friendly practices and materials, aligning with the global trend towards sustainability.

Additionally, the rise of automation and digitalization in manufacturing processes will allow cut wire manufacturers to enhance efficiency, reduce costs, and improve product quality. By leveraging technology, these manufacturers can also better meet the ever-changing needs of their clients and adapt to the challenges of a dynamic market environment.

Conclusion

Cut wire manufacturers play a crucial role in supporting various industries by providing customized wire products that meet specific requirements. From construction to agriculture and automotive sectors, their contributions are indispensable. As the industry continues to evolve with technological advancements and a growing emphasis on quality and sustainability, cut wire manufacturers will undoubtedly remain at the forefront of innovation, delivering solutions that drive progress in numerous fields.

-

Reliable Nails for Every Construction Project

NewsJun.10,2025

-

Reliable Iron Nails for Every Project

NewsJun.10,2025

-

Razor Wire Solutions for Enhanced Security

NewsJun.10,2025

-

Hydraulic Hose Ferrule Fittings: Key to a Strong Hydraulic System

NewsJun.10,2025

-

Field Fencing: Secure Your Property with the Best Solutions

NewsJun.10,2025

-

Euro Fences: The Ultimate Choice for Security and Style

NewsJun.10,2025