Δεκ . 06, 2024 14:56 Back to list

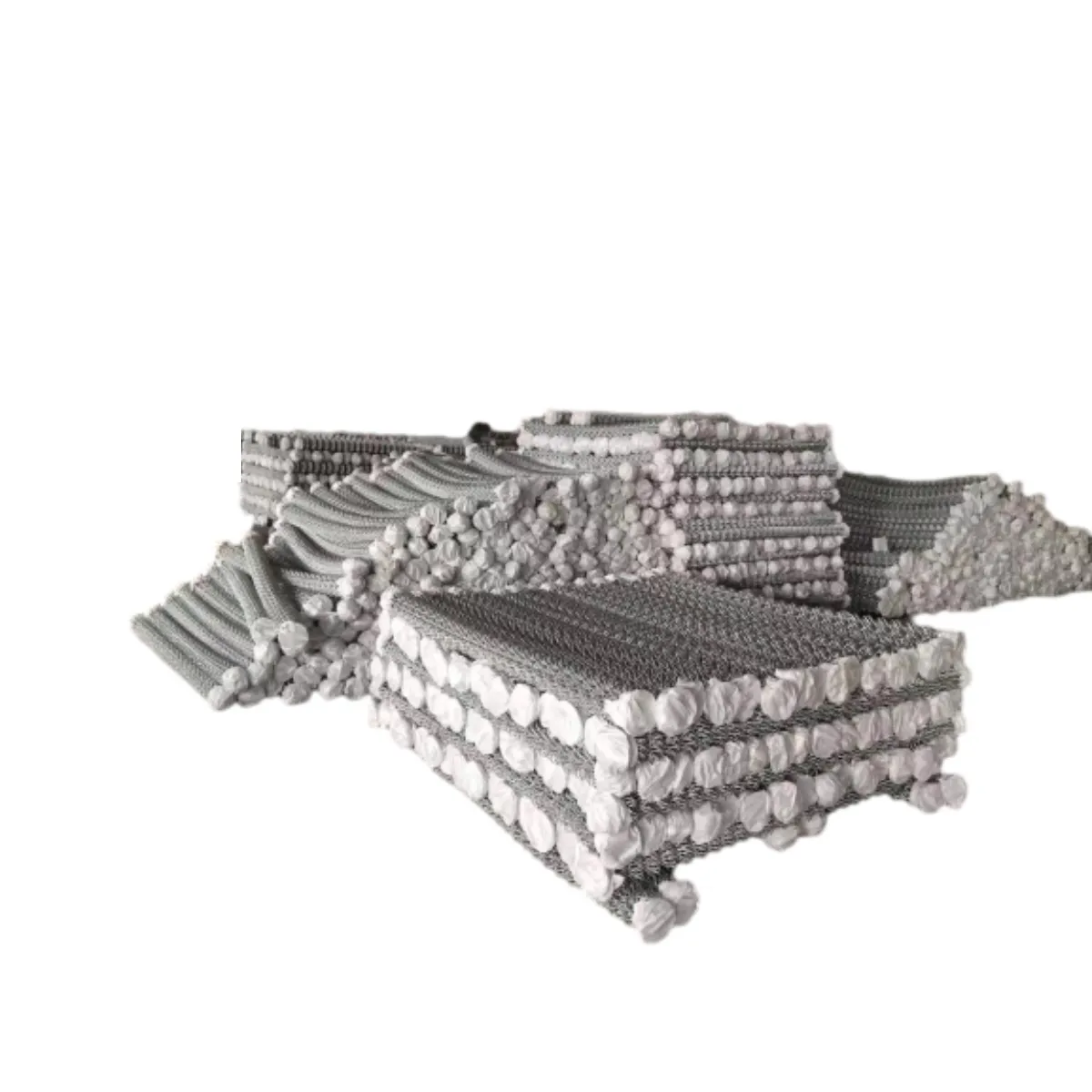

mesh for plastering

Mesh for Plastering The Essential Component for Durable Finishes

Plastering is a crucial aspect of construction and renovation that not only provides an aesthetically pleasing finish but also contributes to the building's structural integrity. Among the various materials used in the plastering process, mesh plays a vital role in ensuring durability and resilience of the plastered surface. This article delves into the significance of mesh for plastering, the types of meshes available, their application methods, and key benefits.

What is Mesh?

Mesh refers to a network of interwoven materials, usually made from metal or synthetic fibers, that act as a reinforcement layer during the plastering process. Its primary purpose is to provide support for the plaster while it cures, preventing cracks and other forms of damage that may occur due to temperature fluctuations, settling, or movement of the building structure.

Types of Mesh for Plastering

There are several types of mesh commonly used in plastering, including

1. Fiber Mesh Typically made from alkali-resistant glass fibers or synthetic fibers, this type of mesh is lightweight and easy to handle. Fiber mesh provides excellent flexibility, making it ideal for surfaces that may undergo slight movements.

2. Steel Mesh Made from galvanized steel, this type of mesh is particularly strong and is often used in industrial applications. Its robust nature provides significant support, making it suitable for areas that experience high stress.

3. Plastic Mesh This is a lightweight and corrosion-resistant option, often used in areas with varying moisture levels. Plastic mesh is easy to work with and can be an economical choice for residential applications.

Application Methods

The application of mesh in plastering involves several steps

1. Surface Preparation Before applying the mesh, the surface needs to be cleaned of dust, grease, or any loose materials. This ensures optimal adhesion of the plaster and mesh.

2. Cutting the Mesh The mesh should be cut into appropriate sizes based on the area being plastered. It is advisable to overlap pieces slightly to ensure complete coverage.

mesh for plastering

3. Adhesive Application A thin layer of adhesive or bedding plaster is applied to the surface. This layer acts as a bonding agent for the mesh.

4. Embedding the Mesh The cut mesh is then laid onto the adhesive layer, using a trowel to press it firmly into place. Care must be taken to avoid air bubbles, as these can weaken the plaster.

5. Applying the Plaster Once the mesh is securely in place, the plaster is applied over it. The mesh should be adequately embedded within the plaster to provide maximum reinforcement.

Benefits of Using Mesh in Plastering

The inclusion of mesh in plastering offers numerous advantages

- Crack Resistance One of the primary benefits of mesh is its ability to minimize cracking in the plaster. By distributing stress evenly over the surface, it prevents localized failures that lead to cracks.

- Improved Bonding Mesh enhances the adhesion of plaster to the substrate, ensuring a longer-lasting and more durable finish. This is particularly important in external applications where weather conditions may affect performance.

- Flexibility Some types of mesh, such as fiber mesh, are highly flexible, allowing them to accommodate slight movements in the structure without compromising the plaster's integrity.

- Moisture Control Certain meshes, especially plastic ones, act as a barrier against moisture ingress, which is crucial in preventing mold growth and degradation of the plaster.

- Time and Cost Efficiency By reducing the likelihood of plaster failure, mesh can save on repair costs and labor time in the long run.

Conclusion

Mesh for plastering is an indispensable component that enhances the performance and longevity of plastered surfaces. Its various types provide options suited for different applications, ensuring that builders and contractors can choose the most appropriate solution for their specific needs. By understanding the importance of mesh and following proper application techniques, one can ensure a durable finish that withstands the test of time, ultimately contributing to the safety and aesthetics of the structure. Whether in residential or commercial projects, the role of mesh in plastering cannot be underestimated, making it a fundamental choice in modern construction practices.

-

Weather Resistance Properties of Quality Roofing Nails

NewsAug.01,2025

-

How Galvanised Iron Mesh Resists Corrosion in Harsh Environments

NewsAug.01,2025

-

Creative Landscaping Uses for PVC Coated Wire Mesh Panels

NewsAug.01,2025

-

Common Wire Nail Dimensions and Their Specific Applications

NewsAug.01,2025

-

Choosing the Right Welded Wire Sheets for Agricultural Fencing

NewsAug.01,2025

-

Anti - Climbing Features of Razor Wire Barriers

NewsAug.01,2025