Σεπ . 28, 2024 20:34 Back to list

Diamond Mesh Manufacturing Solutions for Superior Quality and Durability

The Evolution and Significance of Diamond Mesh in Modern Manufacturing

In the realm of manufacturing, the diamond mesh has emerged as a pivotal element across various industries. Its unique design and versatile applications have made it a favored choice among manufacturers striving for both functionality and aesthetic appeal. Diamond mesh, characterized by its rhombus-shaped openings, marries strength with flexibility, making it ideal for a myriad of uses ranging from construction to decorative purposes.

The Structure of Diamond Mesh

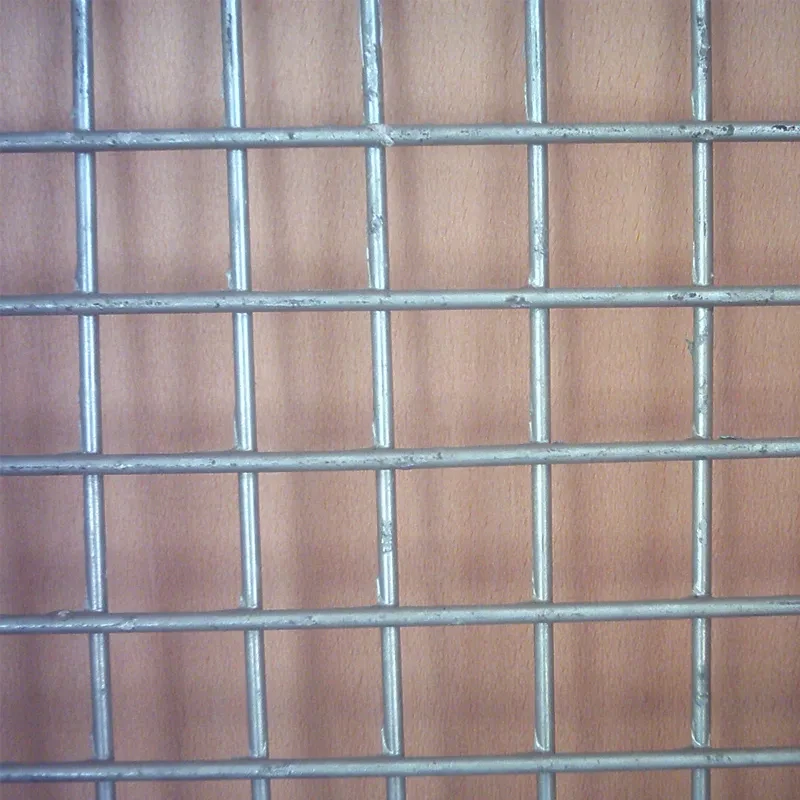

The fundamental structure of diamond mesh comprises interwoven strands of wire that create a continuous and durable grid. This lattice not only serves to provide excellent support but also allows for efficient ventilation, light transmission, and visibility. The diamond pattern optimizes strength while minimizing material usage, making it both an economically and environmentally sensible option for manufacturers.

Materials and Manufacturing Processes

Diamond mesh can be fabricated from various materials, including galvanized steel, stainless steel, aluminum, and plastic. Each material offers distinct advantages; for instance, galvanized steel provides corrosion resistance, making it suitable for outdoor applications, while aluminum offers lightweight durability ideal for easy installation. The manufacturing process can vary, often involving techniques such as welding or weaving to create the desired diamond pattern. Advanced technologies and automated systems have further refined these processes, enhancing precision and scalability to meet growing market demands.

Applications of Diamond Mesh

diamond mesh factory

The applications of diamond mesh are incredibly diverse. In construction, it is used for fencing, security screens, and as reinforcement in concrete structures. Its inherent strength allows it to withstand significant loads, making it a popular choice for safety barriers and construction scaffolds. Moreover, the aesthetic appeal of diamond mesh makes it a suitable option for architectural elements, beautifully combining utility with design.

In industrial settings, diamond mesh can be found in flooring, walkways, and platforms, providing secure footing while allowing for easy drainage. Its use in agriculture is notable as well; for instance, it can be utilized as protective netting for crops or as fencing to safeguard livestock. Additionally, the mesh serves as a foundation for many recreational applications, including sports facilities and playgrounds, adding a layer of safety while promoting an appealing visual aspect to the environment.

The Role of Diamond Mesh Factories

The production of diamond mesh is primarily carried out in specialized factories that focus on the design and manufacture of this versatile product. These factories leverage state-of-the-art machinery and technology to optimize the manufacturing process, ensuring that the diamond mesh produced meets stringent quality standards. Quality control is an essential aspect of manufacturing, as it ensures that the final product is not only durable but also reliable for various applications.

Moreover, the factories often emphasize sustainable practices. This includes using recycled materials when possible and employing energy-efficient production methods to minimize their environmental footprint. As consumers become increasingly conscious of sustainability, diamond mesh factories are adapting to these preferences, thus maintaining their competitive edge in the market.

Conclusion

In conclusion, the diamond mesh factory symbolizes more than just a manufacturing unit; it represents a fusion of tradition and modernity in production techniques, material science, and design philosophy. As industries continue to evolve, the demand for innovative and efficient solutions remains constant, and diamond mesh stands at the forefront. Its myriad applications, coupled with ongoing advancements in manufacturing processes, ensure that diamond mesh will continue to play an integral role in construction, industry, agriculture, and beyond. As society progresses towards a more interconnected and sustainable future, the significance of diamond mesh and its manufacturers will undoubtedly expand, solidifying their place as staples in the landscape of modern manufacturing.

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025