Δεκ . 14, 2024 20:39 Back to list

black anneal wire

The Significance and Applications of Black Anneal Wire

Black anneal wire is a specialized type of wire that has garnered attention in various industrial and construction applications due to its unique properties and versatility. This wire undergoes a specific heat treatment process known as annealing, which significantly alters its physical and mechanical properties, allowing it to serve a broad range of applications effectively. In this article, we delve into the significance, manufacturing process, properties, and diverse applications of black anneal wire.

What is Black Anneal Wire?

Black anneal wire is typically made from low carbon steel, which is subjected to a controlled heating and cooling process. The annealing process not only enhances the wire's ductility and strength but also gives it a characteristic black finish due to the presence of scale and oxidation on its surface. This aesthetic feature makes black anneal wire visually distinct and preferable in certain applications.

Manufacturing Process

The production of black anneal wire begins with cold drawing, a process that reduces the diameter of the wire while increasing its tensile strength. After drawing, the wire is subjected to a heat treatment process in which it is heated to a specific temperature (typically between 600 to 650 degrees Celsius) before being slowly cooled. This annealing process helps relieve internal stresses in the metal, making the wire more ductile and easier to work with. After cooling, the wire is often coated in oil to protect it from corrosion and rust during handling and transportation.

Properties of Black Anneal Wire

One of the primary properties of black anneal wire is its excellent ductility, which allows it to be bent and shaped without breaking. This makes it an ideal material for applications where flexibility is essential. Furthermore, the tensile strength of black anneal wire is often higher than that of other treated wires, making it suitable for load-bearing applications.

Another notable property is its resistance to environmental factors. Although it has a black finish, which may suggest a higher likelihood of corrosion, the oil coating adds a layer of protection. Additionally, the annealing process minimizes brittleness, ensuring that the wire maintains its integrity over time, even in fluctuating temperatures and humidity levels.

black anneal wire

Applications of Black Anneal Wire

Black anneal wire finds extensive use across various industries due to its unique properties. Some common applications include

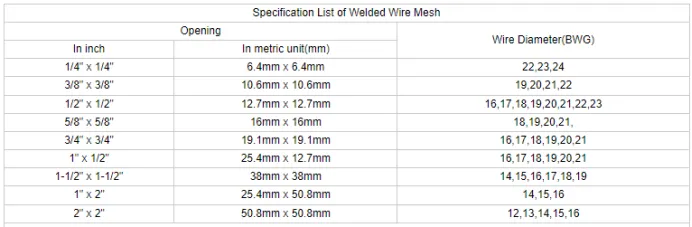

1. Construction and Reinforcement Black anneal wire is widely used in construction for reinforcing concrete structures. The wire's strength and ductility make it an excellent choice for reinforcing bars (rebar) and wire mesh, providing durability and support in building frameworks.

2. Manufacturing and Production In manufacturing, black anneal wire is often used in the production of various products, including springs, industrial fencing, and even automotive components. Its malleability allows for easy styling and reshaping into different forms and components.

3. Agriculture Farmers frequently utilize black anneal wire for fencing and trellising. Its strength helps create robust barriers that can withstand environmental pressures, while its flexibility aids in crafting solutions tailored to various agricultural needs.

4. Craftsmanship and Art Black anneal wire is also popular in art and craft projects. Artists appreciate the wire's malleability, which allows for intricate designs and shapes in sculpture and other artistic endeavors.

5. Electronics and Electrical Applications Due to its conductivity and ease of manipulation, black anneal wire is used in various electronic applications, including winding coils for transformers and inductors.

Conclusion

In summary, black anneal wire represents a vital material in modern industry, weaving its significance into the fabric of construction, manufacturing, agriculture, and art. Its unique combination of strength, ductility, and resistance to environmental factors makes it a preferred choice for numerous applications. As industries continue to evolve, the demand for materials like black anneal wire will undoubtedly persist, underscoring its importance in building a resilient and innovative future.

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025