Ιαν . 15, 2025 04:12 Back to list

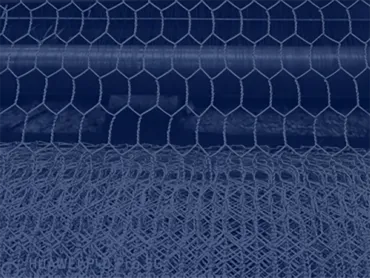

1 2 x 1 2 welded wire

Navigating the world of construction materials can often feel like wandering through a maze—especially when you're searching for something as specific and efficient as 1 2 x 1 2 welded wire. Whether you're a seasoned contractor or an enthusiastic DIY aficionado, understanding the nuances of this product can significantly influence the outcome of your projects. In this exploration, we delve into the transformative potential of 1 2 x 1 2 welded wire, drawing from collective industry expertise and user experiences.

Moreover, its application in agricultural contexts is widespread. The welded wire is adept at withstanding environmental variables, a feature crucial for protecting livestock and crops. Farmers appreciate the material’s robustness against natural elements and potential predators, ensuring both guard and endurance. Here, shared insights underscore its critical role in farm management and its cost-effectiveness over alternatives. When discussing the authoritativeness and trustworthiness of 1 2 x 1 2 welded wire, industry certifications can't be overlooked. Products adhering to ASTM standards are prevalent, guaranteeing a quality that meets rigorous safety and reliability benchmarks. Trust is further reinforced by manufacturers who allow for traceability in their production processes, offering consumers peace of mind about their purchase’s origin and environmental impact. Ultimately, the decision to use 1 2 x 1 2 welded wire in any project is backed by a solid foundation of industry expertise and user testimonies. Its proven performance in diverse scenarios speaks volumes about its effectiveness. Whether enhancing the infrastructure of modern architecture or optimizing the operations on a farm, its benefits are manifold and thoroughly documented by industry experts and end-users alike. Investing in this product is more than just a monetary decision; it’s a commitment to quality and reliability. In a world where cutting corners often leads to failure, opting for a proven product like the 1 2 x 1 2 welded wire is a strategic choice supported by professionals around the globe.

Moreover, its application in agricultural contexts is widespread. The welded wire is adept at withstanding environmental variables, a feature crucial for protecting livestock and crops. Farmers appreciate the material’s robustness against natural elements and potential predators, ensuring both guard and endurance. Here, shared insights underscore its critical role in farm management and its cost-effectiveness over alternatives. When discussing the authoritativeness and trustworthiness of 1 2 x 1 2 welded wire, industry certifications can't be overlooked. Products adhering to ASTM standards are prevalent, guaranteeing a quality that meets rigorous safety and reliability benchmarks. Trust is further reinforced by manufacturers who allow for traceability in their production processes, offering consumers peace of mind about their purchase’s origin and environmental impact. Ultimately, the decision to use 1 2 x 1 2 welded wire in any project is backed by a solid foundation of industry expertise and user testimonies. Its proven performance in diverse scenarios speaks volumes about its effectiveness. Whether enhancing the infrastructure of modern architecture or optimizing the operations on a farm, its benefits are manifold and thoroughly documented by industry experts and end-users alike. Investing in this product is more than just a monetary decision; it’s a commitment to quality and reliability. In a world where cutting corners often leads to failure, opting for a proven product like the 1 2 x 1 2 welded wire is a strategic choice supported by professionals around the globe.

Next:

Latest news

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025