Dez . 31, 2024 23:00 Back to list

Cost Analysis of Welded Wire Mesh Rolls for Various Applications

Understanding Welded Mesh Roll Prices Factors and Trends

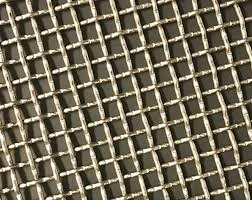

Welded mesh rolls are widely used in various industries and applications, ranging from construction and agriculture to fencing and crafting. These rolls are made from high-quality steel wires that are welded together at junctions, creating a strong, durable mesh. As the demand for welded mesh rolls continues to rise, understanding their pricing dynamics is essential for consumers, manufacturers, and suppliers alike.

What Influences Welded Mesh Roll Prices?

1. Material Costs The primary factor affecting the price of welded mesh rolls is the cost of raw materials. The price of steel can fluctuate based on global market conditions, trade policies, and supply chain disruptions. As steel prices increase, manufacturers may pass on these costs to consumers, resulting in higher prices for welded mesh products.

2. Quality of Material Not all welded mesh rolls are created equal. The quality of the steel used—be it galvanized, stainless, or plain—impacts the cost. Galvanized mesh is often more expensive due to the additional coating process that enhances corrosion resistance, while stainless steel mesh is typically the highest-priced option due to its superior durability and resistance to rust.

3. Mesh Size and Design The size of the welded mesh roll, including the gauge of the wire and the spacing between the welds, significantly influences pricing. Rolls with smaller wire diameters and tighter spacing tend to be more labor-intensive to produce, leading to higher costs. Conversely, larger rolls with fewer weld points may be more affordable but could compromise strength.

weld mesh roll price

4. Production Techniques Advances in manufacturing technology can also affect prices. Automated production lines may reduce labor costs and increase efficiency, allowing manufacturers to offer more competitive pricing. However, specialized production methods that cater to specific applications or industries can increase costs.

5. Market Demand and Seasonal Variability The demand for welded mesh rolls can vary by season, particularly in industries like agriculture and construction. During peak building seasons or when agricultural projects are in full swing, demand may spike, leading to increased prices. Conversely, slow seasons may see reduced prices as suppliers strive to move inventory.

6. Geographical Factors Prices also vary by region due to local demand, shipping costs, and availability of raw materials. Regions with higher production capacities may offer lower prices, while remote areas may incur additional shipping costs, influencing overall pricing.

Trends in Welded Mesh Roll Pricing

As of late 2023, the welded mesh roll market has shown resilience despite global economic uncertainties. A growing emphasis on sustainable construction practices and materials has led to increased investments in high-quality welded mesh, which may affect overall pricing trends. Moreover, with the rise of e-commerce, consumers are increasingly able to compare prices from different suppliers, driving competition and potentially lowering prices.

In conclusion, welded mesh rolls are essential products in numerous industries, and their pricing is influenced by various factors such as material costs, quality, design, production techniques, market demand, and geographical considerations. For those looking to purchase welded mesh rolls, staying informed about these factors and current market trends is crucial for making knowledgeable decisions. As the industry continues to evolve, consumers and businesses should remain adaptable and vigilant to navigate the changing landscape of welded mesh roll pricing.

-

Weather Resistance Properties of Quality Roofing Nails

NewsAug.01,2025

-

How Galvanised Iron Mesh Resists Corrosion in Harsh Environments

NewsAug.01,2025

-

Creative Landscaping Uses for PVC Coated Wire Mesh Panels

NewsAug.01,2025

-

Common Wire Nail Dimensions and Their Specific Applications

NewsAug.01,2025

-

Choosing the Right Welded Wire Sheets for Agricultural Fencing

NewsAug.01,2025

-

Anti - Climbing Features of Razor Wire Barriers

NewsAug.01,2025