Feb. . 18, 2025 05:11 Back to list

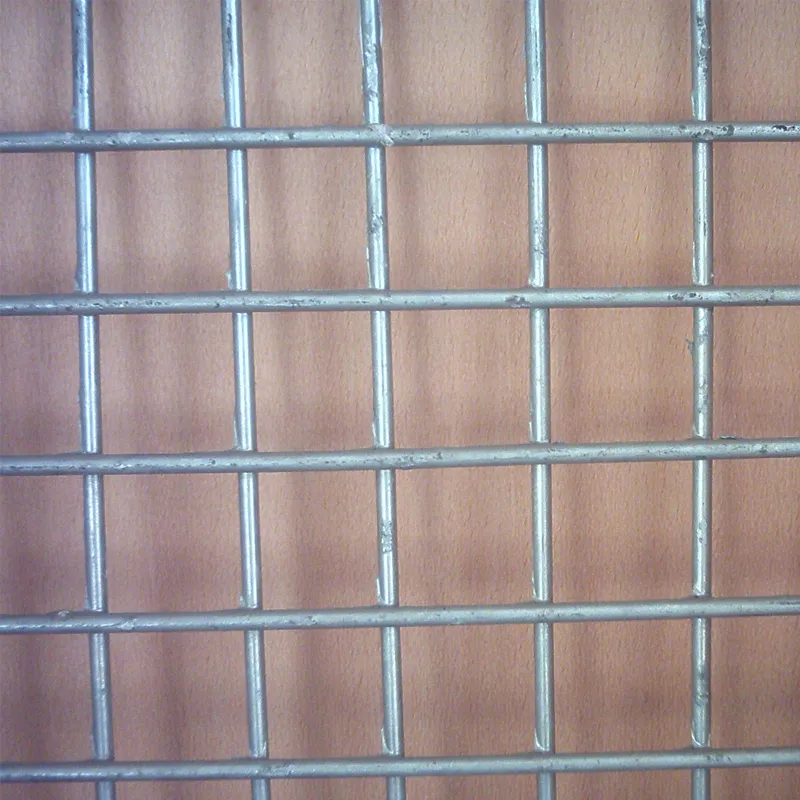

pvc coated wire mesh

PVC coated wire mesh stands as a versatile and reliable product widely used across various industries. Its specific coating offers enhanced durability, corrosion resistance, and aesthetic appeal, catering to both functional and decorative applications. Understanding the true value and multifaceted uses of PVC coated wire mesh is essential for any professional in construction, agriculture, or manufacturing sectors.

Home and garden projects also see the authoritative application of PVC coated wire mesh, illustrating its adaptability beyond industrial use. Garden enthusiasts employ this mesh in landscaping projects to create aesthetically pleasing borders, plant supports, and trellis systems. Its ease of installation and maintenance makes it a favorite among DIY aficionados. Additionally, the color variety available in PVC coatings offers further customization, allowing blends with surrounding decor. Concerning trustworthiness, various certification bodies and regulatory entities recognize PVC coated wire mesh, highlighting its compliance with environmental and safety standards. Certifications such as ISO for quality management and ASTM guidelines for materials ensure consumers and professionals alike of consistent product performance. When considering the environmental impact, PVC coated wire mesh tends to have a reduced ecological footprint. The material is recyclable, with many manufacturers adopting sustainable practices in sourcing raw materials and energy-efficient production methods. This eco-friendly approach not only aligns with global sustainability goals but also appeals to environmentally conscious individuals and organizations. In summary, PVC coated wire mesh stands as a testament to innovation and adaptability across multiple domains. Its remarkable strength, customizable features, and cost-effectiveness make it an indispensable tool for industry professionals and hobbyists alike. Whether addressing safety concerns on agricultural land, reinforcing concrete structures, or beautifying garden spaces, this product offers a reliable solution backed by decades of proven expertise and trustworthiness. As industries continue to evolve, the role of PVC coated wire mesh is poised to expand, meeting new challenges with traditional robustness and innovative design.

Home and garden projects also see the authoritative application of PVC coated wire mesh, illustrating its adaptability beyond industrial use. Garden enthusiasts employ this mesh in landscaping projects to create aesthetically pleasing borders, plant supports, and trellis systems. Its ease of installation and maintenance makes it a favorite among DIY aficionados. Additionally, the color variety available in PVC coatings offers further customization, allowing blends with surrounding decor. Concerning trustworthiness, various certification bodies and regulatory entities recognize PVC coated wire mesh, highlighting its compliance with environmental and safety standards. Certifications such as ISO for quality management and ASTM guidelines for materials ensure consumers and professionals alike of consistent product performance. When considering the environmental impact, PVC coated wire mesh tends to have a reduced ecological footprint. The material is recyclable, with many manufacturers adopting sustainable practices in sourcing raw materials and energy-efficient production methods. This eco-friendly approach not only aligns with global sustainability goals but also appeals to environmentally conscious individuals and organizations. In summary, PVC coated wire mesh stands as a testament to innovation and adaptability across multiple domains. Its remarkable strength, customizable features, and cost-effectiveness make it an indispensable tool for industry professionals and hobbyists alike. Whether addressing safety concerns on agricultural land, reinforcing concrete structures, or beautifying garden spaces, this product offers a reliable solution backed by decades of proven expertise and trustworthiness. As industries continue to evolve, the role of PVC coated wire mesh is poised to expand, meeting new challenges with traditional robustness and innovative design.

Latest news

-

Weather Resistance Properties of Quality Roofing Nails

NewsAug.01,2025

-

How Galvanised Iron Mesh Resists Corrosion in Harsh Environments

NewsAug.01,2025

-

Creative Landscaping Uses for PVC Coated Wire Mesh Panels

NewsAug.01,2025

-

Common Wire Nail Dimensions and Their Specific Applications

NewsAug.01,2025

-

Choosing the Right Welded Wire Sheets for Agricultural Fencing

NewsAug.01,2025

-

Anti - Climbing Features of Razor Wire Barriers

NewsAug.01,2025