Dez . 23, 2024 06:15 Back to list

pre cut wire

The Importance of Pre-Cut Wire in Modern Manufacturing

In the ever-evolving manufacturing landscape, efficiency and precision are paramount. One innovation that has increasingly gained traction is the use of pre-cut wire. This seemingly simple product plays a crucial role in a myriad of applications, from electronics to construction, streamlining processes and reducing costs.

Pre-cut wire refers to wire that has been manufacturer pre-measured and cut to specific lengths, eliminating the need for additional cutting during assembly or installation. This not only saves time but also minimizes errors, ensuring that manufacturers can produce higher-quality products with greater consistency.

Advantages of Pre-Cut Wire

The benefits of using pre-cut wire are numerous. First and foremost, it enhances operational efficiency. In traditional manufacturing settings, workers often spend significant time measuring and cutting wire to the correct length, which can slow down production lines. By utilizing pre-cut wire, manufacturers can dramatically decrease the time spent on these tasks. This allows workers to focus on more complex and value-added activities, ultimately boosting productivity.

Another advantage is the reduction of waste. When wire is cut on-site, there is inevitably excess material that gets discarded. This not only contributes to higher material costs but also poses environmental concerns. Pre-cut wire eliminates excessive waste since it is provided in the exact lengths needed for specific applications. This improved resource management benefits both the bottom line and sustainability efforts.

Pre-cut wire also contributes to improved safety in the workplace. Cutting wire can be hazardous, as it often involves sharp tools and requires careful handling to avoid accidents. By reducing the need for on-site cutting, the risk of injuries can be minimized, providing a safer working environment for employees.

Applications Across Industries

pre cut wire

The versatility of pre-cut wire is evident across various sectors. In the electronics industry, for example, pre-cut wires are widely used for making connections in circuit boards and appliances. This ensures a more reliable and uniform assembly process, ultimately resulting in higher-quality electronic products. Moreover, sectors such as automotive and aerospace benefit from pre-cut wire by ensuring precise lengths for difficult-to-reach areas or intricate designs, enhancing the overall safety and functionality of their products.

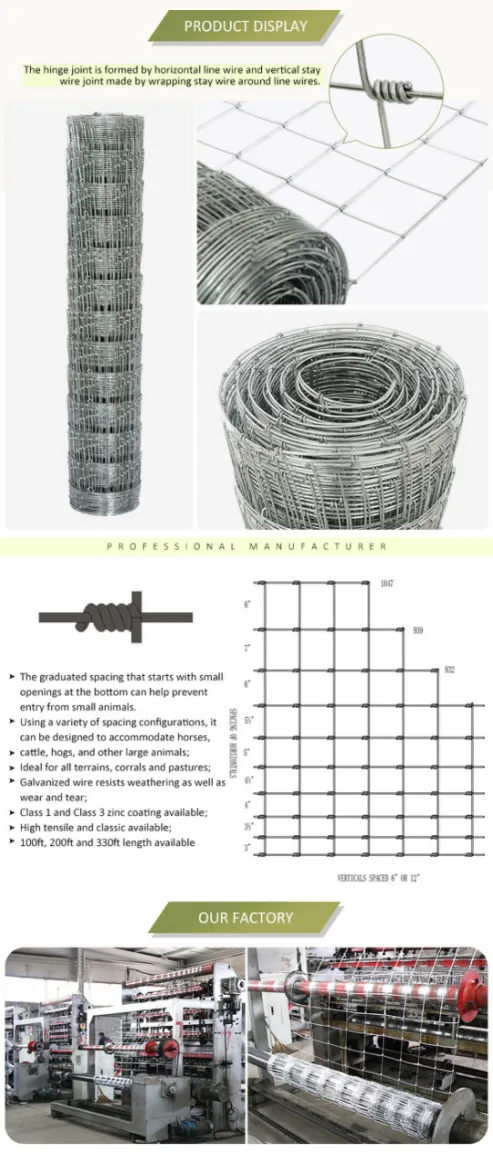

In the construction industry, pre-cut wire can be found in reinforcing and support applications, such as wire mesh panels or concrete reinforcement. The consistent sizing provided by pre-cut wire helps streamline the building process, allowing for quicker installations and improved structural integrity.

Choosing the Right Pre-Cut Wire Supplier

Given the advantages and applications, selecting the right supplier for pre-cut wire is critical. Companies should consider factors such as material quality, precision of cuts, and delivery timeliness. Additionally, customization options can be a deciding factor, as businesses often require specific wire types and lengths that suit their unique processes.

A reputable supplier will not only provide high-quality pre-cut wire but also offer technical support and advice on the best practices for using these products effectively. Establishing a strong relationship with suppliers can also lead to innovations in product offerings, allowing manufacturers to stay ahead of their competitors.

Conclusion

Pre-cut wire is a vital component in modern manufacturing, providing efficiency, precision, and safety improvements across various industries. By eliminating the need for on-site cutting, manufacturers can save time, reduce waste, and enhance the overall quality of their products. As industries continue to embrace the advantages of pre-cut wire, it is evident that this product will play an increasingly important role in shaping the future of manufacturing. As businesses look to optimize their operations, incorporating pre-cut wire into their processes will undoubtedly yield significant benefits, making it a worthwhile consideration for companies aiming for growth and innovation.

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025