nov . 08, 2024 19:50 Back to list

cut wire manufacturer

Cut Wire Manufacturers An Overview of Production and Applications

In the ever-evolving landscape of manufacturing, cut wire has emerged as a significant component across various industries. Cut wire refers to lengths of wire manufactured for specific applications, and it serves as a fundamental material in fields such as construction, electronics, and even art. The production of cut wire involves precisely cutting wire into predetermined lengths, and this process is typically undertaken by specialized manufacturers equipped with the necessary technology and expertise.

Manufacturing Process

The manufacturing process of cut wire begins with the selection of raw materials, which can include different types of metal such as steel, copper, or aluminum. Depending on the end-use, manufacturers may choose wire with specific properties; for instance, high tensile strength is critical for construction applications, while electrical conductivity is paramount for electronic applications.

Once the appropriate wire has been selected, it is subjected to several processes. Initially, the raw wire is unwound from coils and may undergo additional treatments, such as annealing, to enhance its properties. After preparing the wire, manufacturers employ cutting machines that can handle various diameters and lengths. Precision is key in this stage to ensure that each cut meets the specified requirements of clients.

Moreover, quality control is an integral part of the manufacturing process. Manufacturers implement rigorous testing protocols to ensure that the cut wire meets industry standards for strength, dimensions, and surface finish. This may involve tensile testing, dimensional measurement, and inspection for surface defects.

Applications of Cut Wire

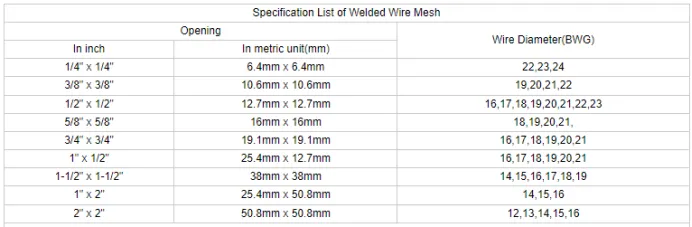

Cut wire finds its applications in numerous sectors. In the construction industry, it is commonly used for reinforcing concrete structures. The wire is often used to manufacture concrete wire mesh, which provides the necessary support to keep concrete from cracking under stress. This application demands cut wire that meets strict compliance regulations regarding strength and durability.

cut wire manufacturer

In the field of electronics, cut wire is utilized in the production of connectors, circuit boards, and various electronic components. The ability to cut wire to specific lengths is essential in achieving the desired performance in electrical applications. Manufacturers often produce cut wire with specific coatings or finishes tailored to resist corrosion and enhance electrical conductivity.

The automotive industry also relies on cut wire for various components, including springs, clips, and fasteners. The precise dimensions and mechanical properties of cut wire play an essential role in the performance and safety of automotive parts. This makes it crucial for manufacturers in this sector to uphold stringent quality standards.

Beyond industrial applications, cut wire also finds its niche in artistic endeavors. Artisans and craftsmen use cut wire for sculpting and crafting. The versatility of cut wire allows artists to create intricate designs, and the variety of metals available offers diverse aesthetic options. From lightweight aluminum to robust steel, cut wire becomes an integral medium in the hands of creative minds.

Market Trends and Innovations

As industries evolve, so too do the demands for cut wire. Recent trends indicate a growing interest in eco-friendly manufacturing processes. Many cut wire manufacturers are now exploring sustainable practices, including the use of recycled materials and environmentally friendly coatings. This shift is driven not only by regulatory pressures but also by consumer demand for more sustainable products.

Furthermore, advancements in technology are facilitating greater automation in the manufacturing process. Automated cutting machines equipped with advanced sensors allow for higher precision and faster production rates, which can significantly reduce lead times and costs for clients. The integration of smart technology also enables better quality control through real-time monitoring of production processes.

Conclusion

Cut wire manufacturers play a critical role in providing a fundamental component for various industries. Through meticulous manufacturing processes and stringent quality control, they ensure that cut wire meets the diverse needs of construction, electronics, automotive, and even artistic applications. As technology progresses and environmental concerns rise, the future of cut wire manufacturing looks poised for innovation and adaptation, ultimately enhancing its significance in the global marketplace.

-

Reliable Nails for Every Construction Project

NewsJun.10,2025

-

Reliable Iron Nails for Every Project

NewsJun.10,2025

-

Razor Wire Solutions for Enhanced Security

NewsJun.10,2025

-

Hydraulic Hose Ferrule Fittings: Key to a Strong Hydraulic System

NewsJun.10,2025

-

Field Fencing: Secure Your Property with the Best Solutions

NewsJun.10,2025

-

Euro Fences: The Ultimate Choice for Security and Style

NewsJun.10,2025