ديسمبر . 05, 2024 15:04 Back to list

mesh for plastering

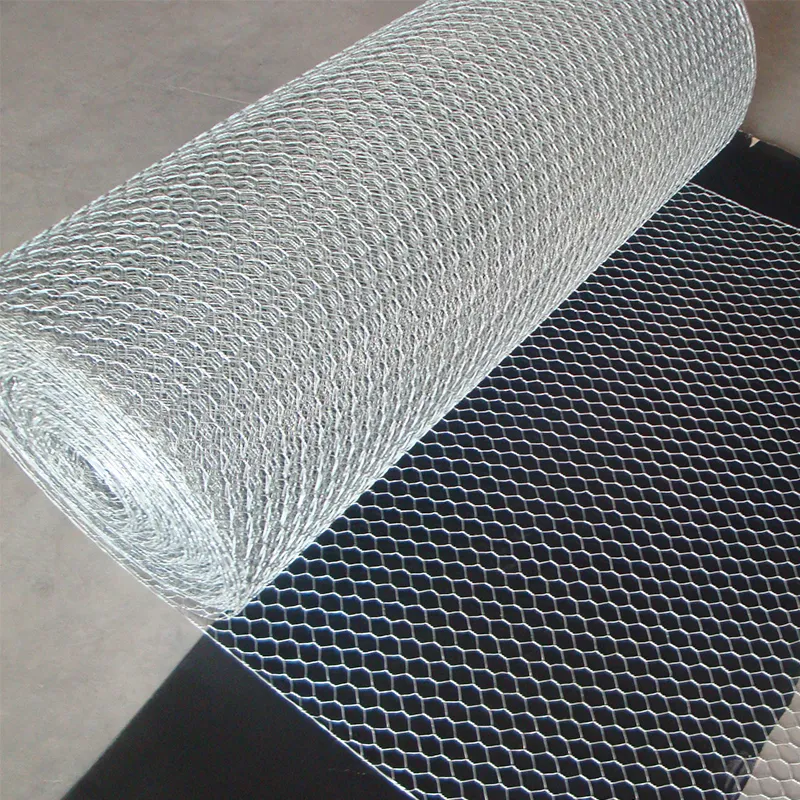

The Importance of Mesh for Plastering in Construction

In the realm of construction, especially when it comes to plastering, the use of mesh is often overlooked but plays a pivotal role in ensuring durability and longevity of plaster finishes. The purpose of this article is to delve into what mesh for plastering is, its benefits, and the best practices for proper implementation.

What is Mesh for Plastering?

Mesh for plastering refers to a reinforcing material typically made from fiberglass, metal, or plastic that is embedded within plaster to enhance its strength and durability. Various types of mesh can be employed, including alkali-resistant fiberglass mesh, stainless steel mesh, and synthetic mesh. Each of these materials offers unique advantages, making it essential to choose the appropriate type depending on the specific application and environmental conditions.

Benefits of Using Mesh in Plastering

1. Crack Prevention One of the most significant benefits of using mesh in plastering is its ability to prevent cracks. As buildings settle over time or experience temperature fluctuations, plaster can be susceptible to cracking. Incorporating mesh during the plastering process provides a structural support that helps distribute stress evenly, drastically reducing the likelihood of cracks developing.

2. Enhanced Adhesion Mesh improves the adhesion of plaster to the substrate. By providing a rough surface, it helps the plaster bond more effectively, ensuring a stronger and more resilient finish. This is especially important when plastering smooth or slick surfaces, where traditional adhesion may falter.

3. Increased Durability The use of mesh increases the overall durability of plaster. This is particularly beneficial in environments that are exposed to harsh weather conditions, such as heavy rain, extreme temperatures, or even high humidity. Mesh-reinforced plaster can withstand more significant stress and is less likely to deteriorate over time.

4. Moisture Resistance Some types of mesh, particularly those made from fiberglass or treated metal, offer improved moisture resistance. This property is essential for exterior applications where exposure to water can lead to degradation of the plaster and subsequent damage to the underlying structure.

5. Improved Aesthetics A well-applied plaster finish with mesh reinforcement often results in a smoother, more uniform surface. This can enhance the overall aesthetic appeal of a project, leading to higher satisfaction for both builders and clients.

mesh for plastering

Best Practices for Using Mesh in Plastering

To ensure that the benefits of mesh are fully realized, several best practices should be observed

1. Proper Selection of Mesh As mentioned, selecting the appropriate type of mesh is crucial. For instance, alkali-resistant fiberglass mesh is commonly used for cement-based plasters while metal mesh may be more suitable for heavy-duty applications.

2. Correct Installation Mesh must be correctly embedded into the plaster to maximize its effectiveness. It should be placed in the middle of the plaster layer and adequately overlapped at the seams to avoid weak points.

3. Layering In thicker plaster applications, multiple layers may be required. Care should be taken to ensure that each layer is given ample time to cure before the next is applied, allowing for better adhesion and structural integrity.

4. Quality Materials Always ensure that high-quality mesh and plaster materials are used to avoid common pitfalls such as peeling or flaking finishes.

5. Professional Application While DIY projects can be fulfilling, engaging experienced professionals for plastering work is often advisable. Their expertise can significantly mitigate issues related to improper installation.

Conclusion

In summary, the integration of mesh in plastering is a crucial element that brings numerous benefits such as crack prevention, enhanced adhesion, and improved durability. By understanding the significance of mesh and adhering to best practices for its application, builders can achieve superior plaster finishes that stand the test of time. As the construction industry continues to evolve, the combination of traditional materials and modern techniques, including the use of mesh, will remain essential for achieving successful and sustainable results in plastering projects.

-

The Role of Field Wire Fence in Grassland Conservation

NewsJul.15,2025

-

Stainless Steel Razor Wire Durability in Coastal Environments

NewsJul.15,2025

-

Enhancing Home Security with Mesh Fences

NewsJul.15,2025

-

Diamond Mesh Wire for Small Animal Enclosures

NewsJul.15,2025

-

Common Wire Nail Tensile Strength Testing for Woodworking

NewsJul.15,2025

-

Barbed Wire Corrosion Resistance Galvanization Techniques

NewsJul.15,2025